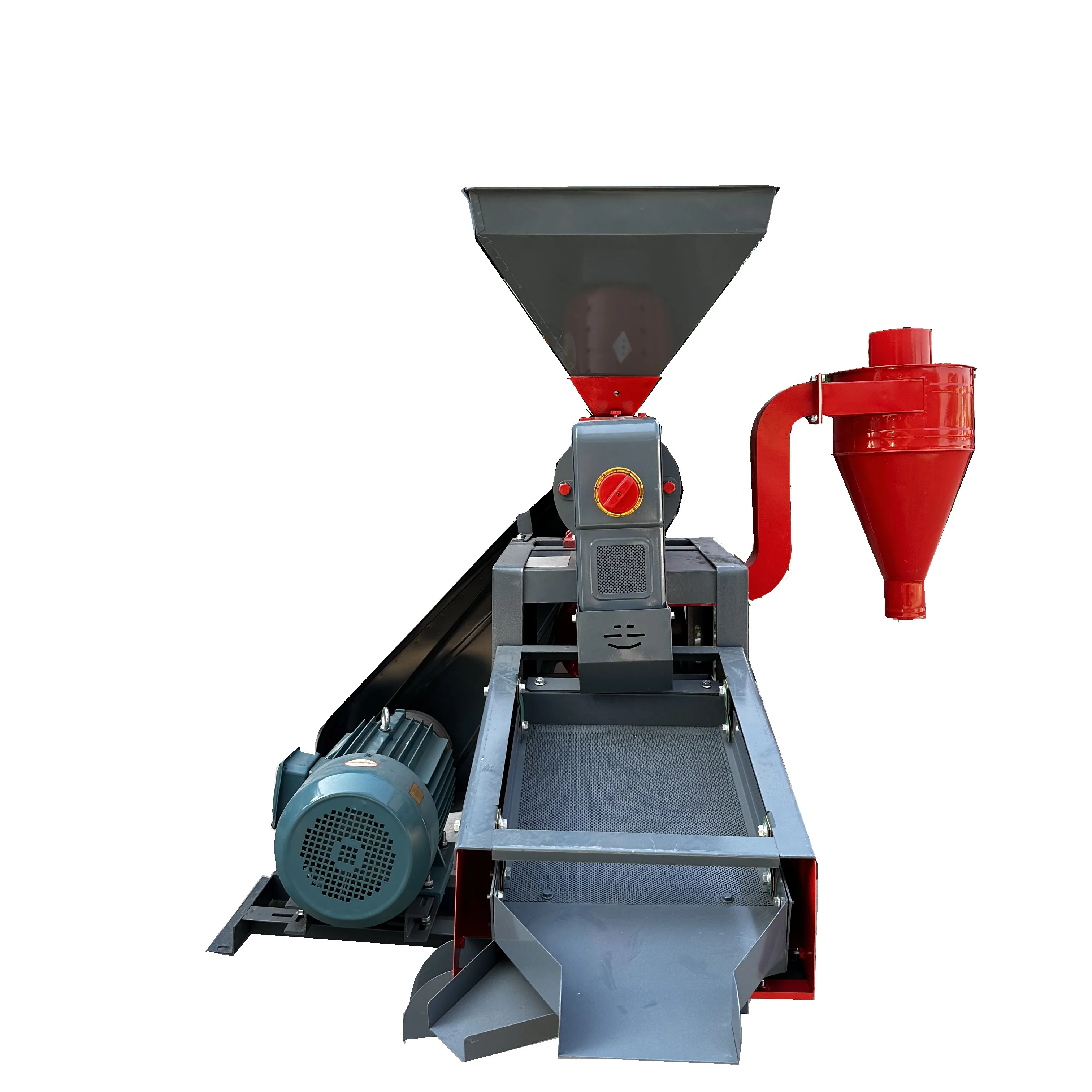

Ammonia sulfate double roller compactor machine with stainless steel in Malaysia

- Category: >>>

- Supplier: Henan Jiuling Machinery Equipment Co. Ltd.

Share on (1601269573916):

Product Overview

Description

Products Description

Stainless Steel Double Roller compactor

The roller compactor is a drying-free granulator, rollers made of high-quality anti-corrosion and wear-resistant stainless steel materials, which can be used for compacting various concentrations and types fertilizer (including organic fertilizer, inorganic fertilizer, biological fertilizer, magnetic fertilizer, etc.) and chemicals,animal feeds,coal etc. and the gearbox is hardened gear reducer, gears are carburized and quenched, gear surfaces are CNC machined and polished, running more smoothly and without noise

Double Roller Extrusion Granulator

The double roller extrusion granulator is the key equipment for compound fertilizer granulation. it has the characteristics of no need for drying after granulation, compact structure, and low energy consumption.lt can be matched with corresponding equipment to form a continuous production line.

The transmission part of the double roller granulator adopts a dual input power transmission method to improve the input power ratio and ensure the lubrication and sealing performance of the transmission gears.

Product details

The all stainless steel machine to prevent chemical raw materials corroding the machine and extend it's service life.

Small power, reliable operation, and low production cost.

The raw material adaptability is wide, and 2.5-40mm particles can be produced. The particle strength is good

Product Advantages

1. Energy saving: compacting dry material, no dryer and cooler, save fuel and electricity

2. No need binders:Granules made by strong extrusion force,no need binder

3. Low investment: No dryer & cooler, the process is simple and the investment is low.

4. Wide range of raw materials: ammonium nitrate, urea, ammonium chloride, calcium nitrate, potassium chloride, potassium sulfate, etc.

5. Environmental friendly: no discharge of industrial waste air and waste water.

Instructions for use:

1. This machine should be started under no-load conditions, and it is strictly prohibited to start it with materials

2. It is strictly prohibited for materials containing iron to enter, in order to avoid breaking the wheel axle.

3. Apply butter to the gear before starting up.

4. Apply butter to the chain and sprocket every 3 days.

5. The bearing seat bearings should be lubricated twice with a grease gun per shift, and the grease inside the bearing chamber should be replaced every three months.

6. Before using the reducer, gear oil must be added once to submerge the large gear by 40-60mm (or two-thirds of the dipstick) before use

Replace the gear oil every four months for production use.

7.After the machine finishes work and the materials are unloaded, it is necessary to clean the internal materials and apply engine oil (waste engine oil is sufficient) to the grinding tool to prevent rust and corrosion.

2. It is strictly prohibited for materials containing iron to enter, in order to avoid breaking the wheel axle.

3. Apply butter to the gear before starting up.

4. Apply butter to the chain and sprocket every 3 days.

5. The bearing seat bearings should be lubricated twice with a grease gun per shift, and the grease inside the bearing chamber should be replaced every three months.

6. Before using the reducer, gear oil must be added once to submerge the large gear by 40-60mm (or two-thirds of the dipstick) before use

Replace the gear oil every four months for production use.

7.After the machine finishes work and the materials are unloaded, it is necessary to clean the internal materials and apply engine oil (waste engine oil is sufficient) to the grinding tool to prevent rust and corrosion.

Product Paramenters

Model | Capacity (t/h) | Power (kw) | Roller size(mm) | Dimension(mm) |

JLJZ-1.0T | 1.0 | 15 | 150*220 | 1450*800*1450 |

JLJZ-1.5T | 1.5 | 22 | 150*300 | 1450*850*1500 |

JLJZ-2.0T | 2 | 30 | 185*300 | 1630*850*1650 |

Roller granulator production line

npk compound Fertilizer Roller compactor Machine double roller granulator is the most commonly used types of granulation equipment, widely used in organic fertilizer and compound fertilizer shaping, petrochemical,food, buding materials, mining and metallurgy, ceramics, and other industries,because it can produce refined granules and provides a highly flexible granulation method. Many variables such as disc angle, speed, feed rate, etc. can be adjusted to control particle size and other characteristics.

No. | Capacity(t/h) | Space(m²) | Power(kw) | Workers |

1 | 1-2 | 2.0K | 170 | 4-7 |

2 | 3-5 | 3.6K | 250 | 4-7 |

3 | 8-10 | 6.3K | 360 | 6-10 |

4 | 15-20 | 7.8K | 600 | 6-10 |

Customer site

30,000T/Year NPK production line feedback from customers in Zimbabwe

Delivery

1.20GP or 40HQ container by sea or train , as well as wooden package

2.Shippment : 10-15 working days once advanced payment.

2.Shippment : 10-15 working days once advanced payment.

Company Profile

Henan Jiuling Machinery Equipment Co., Ltd, which is a famous and large enterprise specialized in researching and developing,

designing, manufacturing and selling organic and compound fertilizer equipment, With more than 18 years of rich production

experience, advanced technical advantages and excellent equipment quality, it has won praise and trust from world-wide. The

company is located in High-tech industrial development zone, Zhengzhou city , Henan province, and we have purchased international

advanced large and medium-sized pecisive Processing Instruments, including 10 CNC processing centers and 3 sets of laser cutting

machines, more than 100 sets of all kinds of equipment in total, to make sure produce the precise working machines.

designing, manufacturing and selling organic and compound fertilizer equipment, With more than 18 years of rich production

experience, advanced technical advantages and excellent equipment quality, it has won praise and trust from world-wide. The

company is located in High-tech industrial development zone, Zhengzhou city , Henan province, and we have purchased international

advanced large and medium-sized pecisive Processing Instruments, including 10 CNC processing centers and 3 sets of laser cutting

machines, more than 100 sets of all kinds of equipment in total, to make sure produce the precise working machines.

Worry free after-sales service

Support customization

Rapid response: real-time online technical consultation.

Quality Assurance: One year warranty (Exclusive wearing spare parts). If any parts are found defectively in quality within guaranty.

Our Services

1.24 hours online technical and business advisory services. | ||||||||

2. Recommend equipment according to raw materials. | ||||||||

3. Provide guidance and free design 3D drawings and CAD site design for your project. | ||||||||

4.Can provide trial video according to customer raw materials. | ||||||||

5.In special cases, it can be shipped quickly. | ||||||||

6.Professional and technical personnel provide equipment installation, commissioning and guidance. | ||||||||

FAQ

1. Will you provide the installation service?

2. These machines can process what kinds of materials?

3. What's Your Quality Guarantee and Certifications?

All of our machine have passed ISO and CE certification, we can guarantee the highest quality and our warranty time is 3 years after shipment date.

4.can we visit your factory before place the order?

You can come Xinzheng airport, Zhengzhou city, We will you pick you up to our factory and to see our customer's fertilizer running plants

2. These machines can process what kinds of materials?

3. What's Your Quality Guarantee and Certifications?

All of our machine have passed ISO and CE certification, we can guarantee the highest quality and our warranty time is 3 years after shipment date.

4.can we visit your factory before place the order?

You can come Xinzheng airport, Zhengzhou city, We will you pick you up to our factory and to see our customer's fertilizer running plants

We Recommend

New Arrivals

New products from manufacturers at wholesale prices