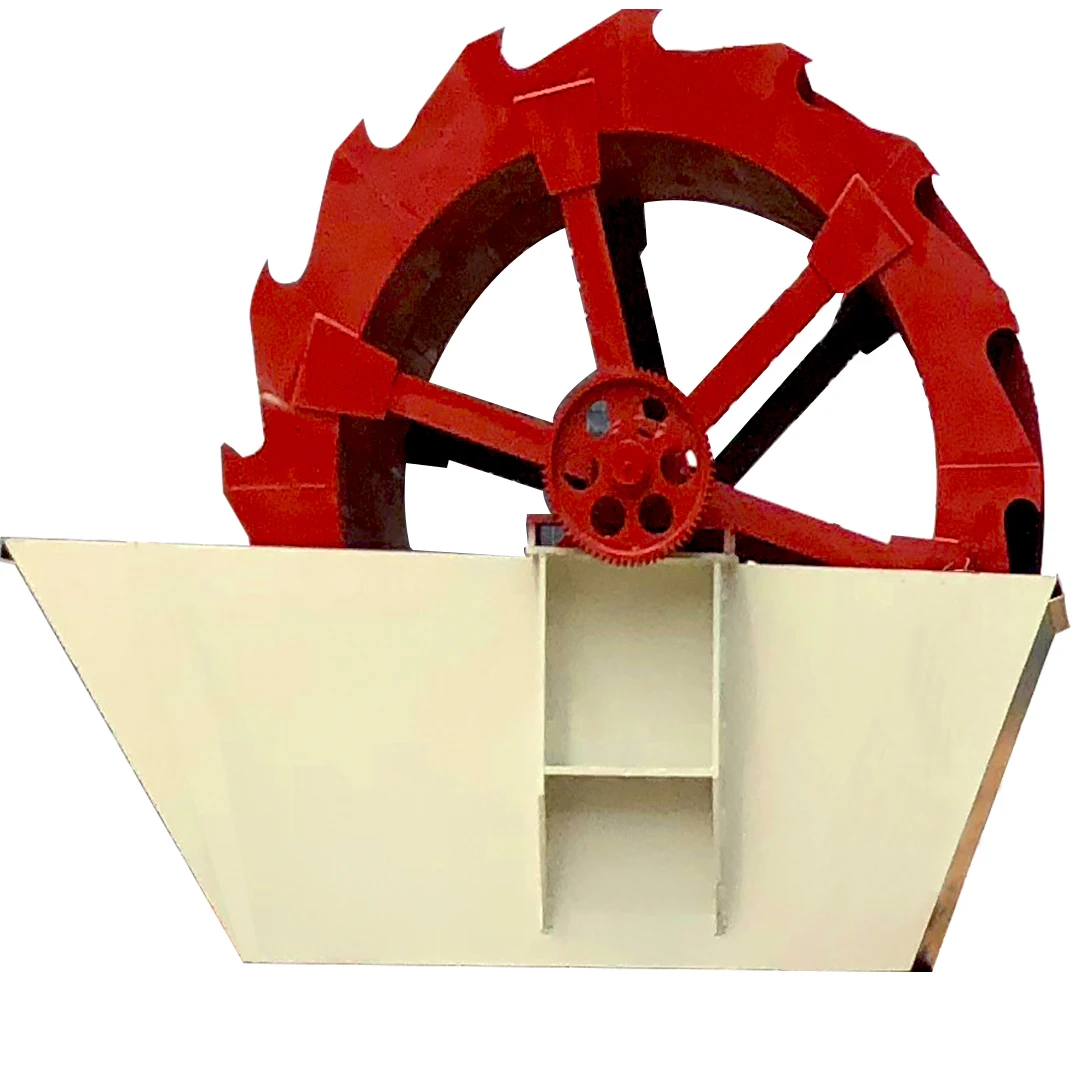

Large spiral sand washing machine equipment complete set of assembly line trough mobile bucket wheel sand washing machine drum

- Category: >>>

- Supplier: Henan Gaoda Machinery Manufacturing Co. Ltd.

Share on (1601269602675):

Product Overview

Description

Wheel sand washing machine product introduction: Bucket sand washing machine is an essential equipment for water-washing sand making used in conjunction with the sand making machine. The sand washing machine can wash away stone powder and impurities from the mixed sand produced by the sand making machine, thereby Improve the quality of sand.

Technical parameters

Model | XSD2610 | XSD2816 | XSD3016 | XSD3620 |

Impeller diameter(mm) | 2600 | 2800 | 3000 | 3600 |

Infeed(mm) | ≤10 | ≤10 | ≤10 | ≤10 |

Throughput(t/h) | 20~60 | 30~60 | 70~120 | 80~160 |

Motor | Y160L-8 | Y180L-8 | Y200L-8 | Y225S-8 |

Power(KW) | 7.5 | 11 | 15 | 18.5 |

Water consumption(t/h) | 10-30 | 10-40 | 10-60 | 20-110 |

Weights(T) | 2.7 | 5.5 | 6.1 | 9.7 |

Dimensions (L x W x H)(mm) | 3254×2060×2622 | 3810×2820×2883 | 3810×2820×3083 | 4624×3443×3680 |

Working principle of the wheel sand washing machine: When the wheel sand washing machine is working, the motor drives the impeller to rotate slowly through the V-belt, reducer, and gear. The sand enters the washing tank from the feeding trough and tumbles under the driving of the impeller. And grind each other to remove impurities covering the surface of the sand and gravel, and at the same time destroy the water vapor layer coating the sand grains to facilitate dehydration; at the same time, add water to form a strong water flow, which can promptly take away impurities and foreign objects with small specific gravity, and discharge them from the overflow outlet washing tank , to complete the cleaning effect. The clean sand and gravel are taken away by the blades, and finally the sand and gravel are poured from the rotating impeller into the discharge trough to complete the cleaning effect of the sand and gravel.

Advantages of wheel sand washing machine:

1.Simple structure and stable operation.

2.Separate the bearings from water and materials to avoid premature damage to the machine caused by contamination and rust.

3.Suitable for various working environments.

4.There is less loss of washed materials and high washing efficiency, which can fully meet the requirements of high-grade materials.

5. The service life is relatively long and there are almost no wearing parts.6. Repair is rarely required, so the cost can be greatly reduced.

1.Simple structure and stable operation.

2.Separate the bearings from water and materials to avoid premature damage to the machine caused by contamination and rust.

3.Suitable for various working environments.

4.There is less loss of washed materials and high washing efficiency, which can fully meet the requirements of high-grade materials.

5. The service life is relatively long and there are almost no wearing parts.6. Repair is rarely required, so the cost can be greatly reduced.

Guangxi Liuzhou Powder Production Line

African gold mine washing project

Indonesian tailings washing complete process

Q: How long is your delivery time?

A: 7-10 days for the stock, 15-30 days for the mass production.

Q: How long is the warranty? Does your company supply the spare parts?

A: One year. Spare parts for you at lowest cost.

Q: If I need the complete crushing plant can you help us to build it?

A: Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

Q: What are the special advantages of the Jaw crusher equipment?

A: These Jaw crushers have features of a deep, symmetrical crushing chamber, easy settings adjustment, a large feed opening for its size, and an ideal nip angle that offers smooth material flow and high reduction efficiency.

A: 7-10 days for the stock, 15-30 days for the mass production.

Q: How long is the warranty? Does your company supply the spare parts?

A: One year. Spare parts for you at lowest cost.

Q: If I need the complete crushing plant can you help us to build it?

A: Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

Q: What are the special advantages of the Jaw crusher equipment?

A: These Jaw crushers have features of a deep, symmetrical crushing chamber, easy settings adjustment, a large feed opening for its size, and an ideal nip angle that offers smooth material flow and high reduction efficiency.

Company Information

Henan Gaoda Mechanical Manufacturing Co., Ltd. is located on the Central West Road of Gongyi City, Henan Province. It is a professional manufacturer of mining equipment and environmental protection equipment, with many years of technical strength and experience. The main products developed and produced are: crushing equipment, sand making equipment, screening and washing equipment, mobile crushers, mobile screening equipment, sand washing and recovery equipment, dehydration screens, vibrating screen separators, etc. 5 major series and nearly 50 products, which are widely sold to various parts of China as well as Indonesia, Iran, Russia, Pakistan, India, South Africa and other 10 countries.

We Recommend

Silica Sand Washing and Flotation Process for Pure SiO2

$30,500.00-35,000.00

High Efficiency Mining Quarry Bulk Stone Rock Vibrating Feeder

$8,500.00-10,000.00

Factory Direct Sale 60 Ton Mining Dump Truck Heavy Mining Equipments Truck

$25,000.00-41,000.00

New Arrivals

New products from manufacturers at wholesale prices