Manual Brick Making Machine In Papua New Guinea Extrusion Screw Chinese Block Machine

- Category: >>>

- Supplier: Gongyi Shield Machinery Manufacturing Co. Ltd

Share on (1601270790607):

Product Overview

Description

Products Description

Gongyi Dunpai Machinery Factory produces a non-steam aerated block brick laying machine (Lightweight bricks making machine) which mainly passes waste resources such as fly ash, slag, sand and other waste resources through the brick making machine to produce lightweight bricks. The production process is simple, the investment is small, and the cost is low. Good quality, environmental protection and energy saving.

Technical Parameters

Product Name:Electronic Batching Machine

Boundary Dimension:5.60*1.80*2.80m

The raw materials are proportioned and weighed by the automatic batching system.

Boundary Dimension:5.60*1.80*2.80m

The raw materials are proportioned and weighed by the automatic batching system.

Technical Parameters

Product Name: Foaming Stirring Mainframe

Power:11kw

Boundary Dimension:4.00*2.20*2.00m

The machine mixes raw materials and foaming machine to form slurry.

Power:11kw

Boundary Dimension:4.00*2.20*2.00m

The machine mixes raw materials and foaming machine to form slurry.

Technical Parameters

Product Name:Demoulding Machine

Power:4.5kw

Boundary dimension:6.00*2.50*2.20m

Lift the mold by the ferry car for holding mold, and then transport it to the cutting machine.

Power:4.5kw

Boundary dimension:6.00*2.50*2.20m

Lift the mold by the ferry car for holding mold, and then transport it to the cutting machine.

Technical Parameters

Product Name:Surface Cutting Machine

Power:11kw

Power:11kw

Boundary Dimension:3.25*0.5*1.90m

Make the surface of the semi-production flat.

Make the surface of the semi-production flat.

Technical Parameters

Product Name: Saw Blade Cutting Machine

Power:4.5kw

Boundary Dimension:2.00*2.00*2.00m

We can use the cutting machine to cut the semi-finished product according to your need.

Power:4.5kw

Boundary Dimension:2.00*2.00*2.00m

We can use the cutting machine to cut the semi-finished product according to your need.

Technical Parameters

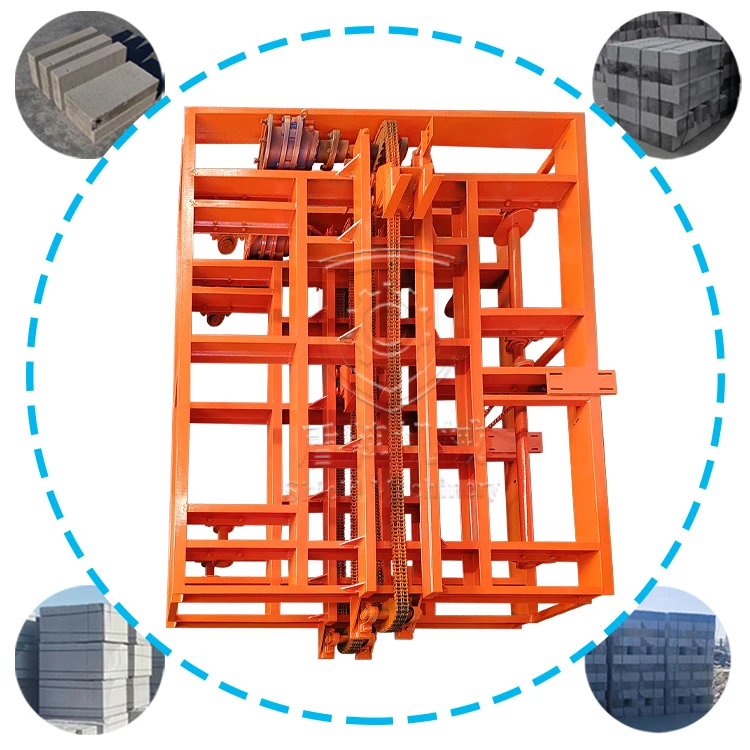

Product Name:Palletizing Machine

Boundary Dimension:1.40*1.50*1.33m

Stacker Machine is used for brick clamping, and crane and forklift can be used.

Boundary Dimension:1.40*1.50*1.33m

Stacker Machine is used for brick clamping, and crane and forklift can be used.

Technical Parameters

Product Name:Rail Changing Trolley

Boundary dimension:1.40*1.40*0.80m

Ferry car from one track to another track for continuous production.

Technical Parameters

Product Name:Mold

Boundary dimension:1.20*1.20*0.60m

Pour the slurry into the mold and wait for chemical foaming.

Production line layout

Gongyi Dunpai Machinery Factory produces a non-steam aerated block bricklaying machine ( Lightweight bricks making machine) which has many advantages:

1.Simple operation, technical guidance ;

2.Diverse models, accept customization;

3.No need to assemble, plugand play;

4.Precision machining, humanized design ;

5.The first domestic patent brick making.

Finished product display and application

Lightweight bricks are also called polystyrene foam bricks or steam-free aerated block bricks. It can be used in various building facilities, and has the advantages of heat preservation, heat insulation, sound insulation, etc., and has good earthquake resistance, compression resistance and waterproof performance. More environmentally friendly than ordinary bricks, so it is now used more.

Specification

Foam Concrete Non Autoclaved Aerated Brick Block | ||||

Model | Capacity | Power | ||

CLC-50 | 50 m³/day | 27.5 KW | ||

CLC-100 | 100 m³/day | 84.5 KW | ||

CLC-200 | 200 m³/day | 179 KW | ||

CLC-300 | 300 m³/day | 317.6 KW | ||

Notes:Can be customized according to customer needs | Can be customized according to customer needs | |||

Our Advantages

The main advantage of our block making machine.

1.Our block machine is one of our newly designed block making machine with less power.

2.It adopts full automatic spiral material laying method, so the material in the mould is well-distributed. With simple operation and high productivity, when producing hollow blocks, it has an advantage over the large hydraulic block machines.

3.It uses Mode 350 speed reducer to raise and lower the mold, so it greatly increases the usage life of the speed reducer.

4.The blocks made by this machine has high strength and accurate size.Its performance and product quality are comparable to the large equipment.

Company Profile

Gongyi Shield Machinery Manufacturing Co., Ltd. is an enterprise specializing in machinery development, manufacturing and exporting. The company was founded in 1985, with an annual turnover of more than 2 million dollars. The company now mainly produces and sells new building materials machinery and equipment, renewable resources utilization machinery and equipment. The company has passed the ISO9001 management system and EU CE certification, adopting advanced manufacturing technology and humanized design concepts, as well as exquisite welding automation technology and 6S testing and acceptance management system. It ensures the scientific advancement, quality standardization and management systemization of the equipment. After more than 30 years of R & D and manufacturing of all staff, has now formed a scientific research, manufacturing and sales as one of the specialized machinery manufacturing production enterprises, the products have been sold to more than a dozen countries around the world, by the user's wide range of unanimous praise.

Packaging&Shipping

Packaging:First, wrap the mechanical equipment with lastic wrap, and then put the wrapped mechanical quipment into the wooden box after packaging.

Shipping:First by truck to the port, and then by sea to the destination.

Shipping:First by truck to the port, and then by sea to the destination.

FAQ

1.What are the required raw materials?

Main materials: water, cement Auxiliary materials: polystyrene particles / sand / stone powder / fly ash / tailings / slag / construction waste (any one can be used) foaming agent.

Electronic batching machines, conveyors, foam mixing machines, mold lifting ferry machines, cutting machines, palletizers, ferry cars, traction equipment.

3.how is the quality of the final aerated blocks produced by your machine?

According to the different raw materials and formulas, the compressive strength of the bricks produced by our equipment is between 2.5-4.7N/mm². The exclusive formula will be provided based on the material you will choose before the purchase ends.

4.what kinds of NON-AAC block-making machines do you provide?

Based on the different techniques of foaming we produce chiemical type and physical type.

Based on the different capicities you will need ,we produce the following basic type: QT-C-50;QT-C-100;QT-C-200;QT-P-50;QT-P-100;QT-P-200; Daily output ranges from 50 cubic meters to 200 cubic meters or more.

5.What are the advantages of autoclaved aerated block production equipment compared with traditional autoclaved equipment?

√ 60-90% investment cost savings, because we use the developed formula to replace the boiler autoclave.

√ There is no exhaust gas, waste water, solid waste discharge, and the energy saving rate is more than 50%.

√ Minimal site, labor requirements, and high production efficiency. Daily output of 100 party lines only 4-5 people, no heavy

physical and hazardous work.

√ No specific production environment is required. Normal temperature and pressure can guarantee product quality.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices