Laser code system for inside and outside bottle caps UV laser marking machine Laser marking with variable data Qr code traceable

- Category: >>>

- Supplier: Guangzhou Bimeigao Intelligent System Technology Co. Ltd.

Share on (1601271313144):

Product Overview

Description

FEATURES AT A GLANCE

Bottle cap coding, collection, detection, and traceability integrated equipment

Equipment composition: The plastic bottle cap laser marking system mainly consists of eight parts: variable data coding system,

cap sorting system, buffer feeding mechanism, bottle cap spacing mechanism, ultraviolet laser marking system, visual scanning

recognition and removal system, air purification system, and point sorting mechanism.

Function and configuration: Adopting an automatic feeding waterfall type capping mechanism, the automatic feeding function is

achieved. Two sets of high-speed online marking ultraviolet laser systems simultaneously laser mark the inner and outer codes of

the bottle cap, which can identify the two-dimensional code and character code on the surface of the product. Two sets of code

reading visual recognition systems are used to automatically recognize the inner and outer codes of the cap and associate variable

data. For those that cannot be recognized, automatic online reading and elimination are carried out to ensure the readability of

the inner and outer codes of the bottle cap, ensuring that the pass rate of bottle cap coding after elimination is ≥ 99.9%.

Main functions of the bottle cap online labeling system

1) Marking function: It can mark Chinese and English text, time and date, serial number, etc., and output Chinese and English,

graphics, and various QR codes. The font library is fully functional and can support personalized special characters;

2) QR code marking function: It can realize variable data transmission of the QR code system, generate various variable QR code

data, and upload data functions;

3) Data system function: Based on different data systems, it can achieve real-time communication between network and serial ports,

receive data encoding, or directly read MDB databases, TXT, and Excel files;

4) Anti tampering code function: customizable area codes for dealer management, anti-counterfeiting and anti smuggling measures.

5) Production tracking function: It can save data such as production shifts, time, and content for easy supervision and tracking.

6) Automatic counting and packing function: The system marks completion while achieving automatic counting. There are two channels

at the counting and packing port. When box A is full, it switches to box B to start packing and emits an audible and visual alarm

to remind the operator to replace the empty box. This cycle continues.

cap sorting system, buffer feeding mechanism, bottle cap spacing mechanism, ultraviolet laser marking system, visual scanning

recognition and removal system, air purification system, and point sorting mechanism.

Function and configuration: Adopting an automatic feeding waterfall type capping mechanism, the automatic feeding function is

achieved. Two sets of high-speed online marking ultraviolet laser systems simultaneously laser mark the inner and outer codes of

the bottle cap, which can identify the two-dimensional code and character code on the surface of the product. Two sets of code

reading visual recognition systems are used to automatically recognize the inner and outer codes of the cap and associate variable

data. For those that cannot be recognized, automatic online reading and elimination are carried out to ensure the readability of

the inner and outer codes of the bottle cap, ensuring that the pass rate of bottle cap coding after elimination is ≥ 99.9%.

Main functions of the bottle cap online labeling system

1) Marking function: It can mark Chinese and English text, time and date, serial number, etc., and output Chinese and English,

graphics, and various QR codes. The font library is fully functional and can support personalized special characters;

2) QR code marking function: It can realize variable data transmission of the QR code system, generate various variable QR code

data, and upload data functions;

3) Data system function: Based on different data systems, it can achieve real-time communication between network and serial ports,

receive data encoding, or directly read MDB databases, TXT, and Excel files;

4) Anti tampering code function: customizable area codes for dealer management, anti-counterfeiting and anti smuggling measures.

5) Production tracking function: It can save data such as production shifts, time, and content for easy supervision and tracking.

6) Automatic counting and packing function: The system marks completion while achieving automatic counting. There are two channels

at the counting and packing port. When box A is full, it switches to box B to start packing and emits an audible and visual alarm

to remind the operator to replace the empty box. This cycle continues.

PRODUCT SPECIFICATIONS

Equipment composition

Laser marking system

The main function is to perform online dynamic QR code marking on the inner and outer codes of bottle caps;

Waterfall type capping machine

The main function is to organize the bottle cap, with the cap facing in one direction, and output it to the laser marking system

for marking. The host adopts variable frequency speed regulation and the main material is made of stainless steel.

Wind supply channel

The system is followed by a capping machine, which transports the bottle caps to the laser marking conveyor line in the direction

of use.

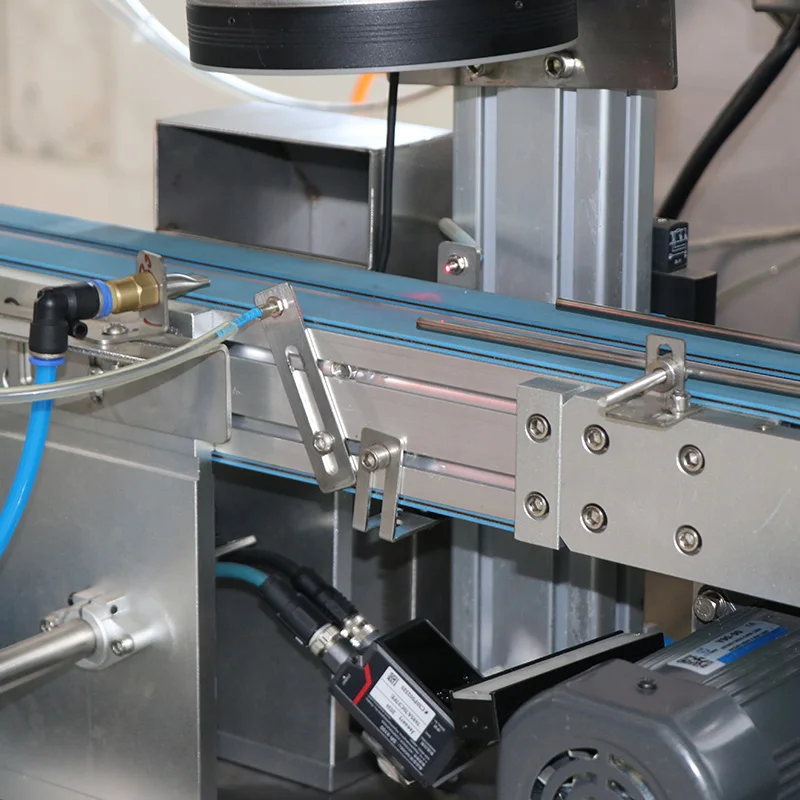

Split cover mechanism system

The device pulls the bottle cap apart and transports it to the vacuum conveyor belt, using a micro servo motor controlled cap

separation system. The split cap is made of wear-resistant metal encapsulation material, and hand cranked clamping can be used for

bottle caps of different sizes, requiring equal spacing between bottle caps.

Vacuum adsorption conveying system

This system is connected to a cap separation system, which uses vacuum adsorption to transport bottle caps for stable QR code

coding and marking by two sets of laser machines. This system is controlled by servo power.

Positive and negative bottle cap mechanism

The mechanism connects the upper and lower conveyor lines to complete the turning of bottle caps on both sides;

Laser marking system

The main function is to perform online dynamic QR code marking on the outer code of bottle caps;

Code reading recognition system

The system includes detection lenses, controllers, industrial intelligent cameras, etc., which can be used to detect the

readability of QR codes on bottle caps after labeling, and to reject bottle caps that fail to read information.

Data code association

The software system implements the association of data inside and outside the bottle cap and generates the outer box code to

complete the three in one process, and the printer prints the label code.

Electrical control system

This system is used to control the entire production line, including the air supply channel, cover separation mechanism system,

vacuum conveyor belt, and visual code reading system.

Pneumatic control system

This system is used to control the entire production line. Including gas source distributor, filter, cylinder, flow control valve,

solenoid valve, etc.

Air purification system

This system is used for vacuuming and filtering the gases and dust emitted by the laser machine during operation.

Laser marking system

The main function is to perform online dynamic QR code marking on the inner and outer codes of bottle caps;

Waterfall type capping machine

The main function is to organize the bottle cap, with the cap facing in one direction, and output it to the laser marking system

for marking. The host adopts variable frequency speed regulation and the main material is made of stainless steel.

Wind supply channel

The system is followed by a capping machine, which transports the bottle caps to the laser marking conveyor line in the direction

of use.

Split cover mechanism system

The device pulls the bottle cap apart and transports it to the vacuum conveyor belt, using a micro servo motor controlled cap

separation system. The split cap is made of wear-resistant metal encapsulation material, and hand cranked clamping can be used for

bottle caps of different sizes, requiring equal spacing between bottle caps.

Vacuum adsorption conveying system

This system is connected to a cap separation system, which uses vacuum adsorption to transport bottle caps for stable QR code

coding and marking by two sets of laser machines. This system is controlled by servo power.

Positive and negative bottle cap mechanism

The mechanism connects the upper and lower conveyor lines to complete the turning of bottle caps on both sides;

Laser marking system

The main function is to perform online dynamic QR code marking on the outer code of bottle caps;

Code reading recognition system

The system includes detection lenses, controllers, industrial intelligent cameras, etc., which can be used to detect the

readability of QR codes on bottle caps after labeling, and to reject bottle caps that fail to read information.

Data code association

The software system implements the association of data inside and outside the bottle cap and generates the outer box code to

complete the three in one process, and the printer prints the label code.

Electrical control system

This system is used to control the entire production line, including the air supply channel, cover separation mechanism system,

vacuum conveyor belt, and visual code reading system.

Pneumatic control system

This system is used to control the entire production line. Including gas source distributor, filter, cylinder, flow control valve,

solenoid valve, etc.

Air purification system

This system is used for vacuuming and filtering the gases and dust emitted by the laser machine during operation.

Main functions of the bottle cap online labeling system

1) Marking function: It can mark Chinese and English text, time and date, serial number, etc., and output Chinese and English,

graphics, and various QR codes. The font library is fully functional and can support personalized special characters;

2) QR code marking function: It can realize variable data transmission of the QR code system, generate various variable QR code

data, and upload data functions;

3) Data system function: Based on different data systems, it can achieve real-time communication between network and serial ports,

receive data encoding, or directly read MDB databases, TXT, and Excel files;

4) Anti tampering code function: customizable area codes for dealer management, anti-counterfeiting and anti smuggling measures.

5) Production tracking function: It can save data such as production shifts, time, and content for easy supervision and tracking.

6) Automatic counting and packing function: The system marks completion while achieving automatic counting. There are two channels

at the counting and packing port. When box A is full, it switches to box B to start packing and emits an audible and visual alarm

to remind the operator to replace the empty box. This cycle continues.

1) Marking function: It can mark Chinese and English text, time and date, serial number, etc., and output Chinese and English,

graphics, and various QR codes. The font library is fully functional and can support personalized special characters;

2) QR code marking function: It can realize variable data transmission of the QR code system, generate various variable QR code

data, and upload data functions;

3) Data system function: Based on different data systems, it can achieve real-time communication between network and serial ports,

receive data encoding, or directly read MDB databases, TXT, and Excel files;

4) Anti tampering code function: customizable area codes for dealer management, anti-counterfeiting and anti smuggling measures.

5) Production tracking function: It can save data such as production shifts, time, and content for easy supervision and tracking.

6) Automatic counting and packing function: The system marks completion while achieving automatic counting. There are two channels

at the counting and packing port. When box A is full, it switches to box B to start packing and emits an audible and visual alarm

to remind the operator to replace the empty box. This cycle continues.

This is the vibrating lens of a laser machine. Its role is to scan the light emitted by the laser head. During the scanning

process, the vibrating lens will vibrate at high speed along the X and Y axes. This enables laser scanning in a two-dimensional

plane. When the laser is focused through the focusing mirror, a certain light spot is formed on the processed material. This light

spot can cut and carve the material. The performance of the vibrating lens directly affects the machining accuracy and speed of

the laser machine. Therefore, when choosing the laser machine, we must pay attention to the selection of the vibration lens.

process, the vibrating lens will vibrate at high speed along the X and Y axes. This enables laser scanning in a two-dimensional

plane. When the laser is focused through the focusing mirror, a certain light spot is formed on the processed material. This light

spot can cut and carve the material. The performance of the vibrating lens directly affects the machining accuracy and speed of

the laser machine. Therefore, when choosing the laser machine, we must pay attention to the selection of the vibration lens.

uv laser marking machine technical parameters | ||

Scope of application | Bottle cap printing two-dimensional code, ceramic cutting, FPCB cutting, PCB drilling, ITO film etching, glass engraving, microhole processing and other plastic, silicone, metal or non-metal surface marking | |

Equipment type | UV-X330/X530/X100/X150/X200 | |

Laser power | 3W/5W/10W/15W/20W | |

Laser type | Pulsed UV Solid Laser (wavelength 355) | |

Electricity demand | 220V,AC50/60HZ,1KVA | |

Maximum straight line scale | 13000MM/S | |

Operating interface | 10 inch integrated touch screen/computer | |

Positioning mode | Focus red light, preview red light | |

Marking format | 70MM-800MM(selectable) | |

Communication interface | USB/RS232/Net interface | |

Title goes here.

UV laser marking machine uses ultraviolet laser output wavelength of 355 nm laser. The laser beam has a very high energy after focusing, and can generate enough heat energy on the surface of various materials to vaporize the surface material or change the color

UV laser marking machine uses ultraviolet laser, short wavelength, high energy, high power density, so the carved text pattern is very fine. Also, it doesn't produce a laser pattern, so it doesn't leave a scorch mark. At the same time, it will not produce harmful substances, more environmentally friendly.

Laser coding technology is a non-contact processing method that will not cause any pollution to the product itself. Moreover, the effect of laser coding is very clear and durable..

Company certificate

SALES AND SERVICE NETWORK

SIMILAR PRODUCTS

FAQ

1.Who are We?

Our factory is located in Guangdong, China and was established in 2009.

2. How can I get the best machine for me?

You can tell us your working material, detail work by picture or video so that we can judge whether our machine can meet your needs or not. Then we can give you the best machine depends on our experience.

3. This is the first time I use this kind of machine, is it easy to operate?

We will send you manual and guide video in English, it can teach you how to operate the machine. If you still can not learn how to use it, we can help you by video connection online help you.

4.What can you buy from us?

We supply laser machines and production solution. Laser machines include CO2 laser marking machine, UV laser marking machine, Optical Fiber laser marking machine. Production solution include visual positioning system, visual inspection equipment and system, anti-counterfeiting anti-channeling traceability system, production management system, quality assurance system, marketing system, etc. Laser marking machine and visual inspection equipment can be customized.

5.Why do you buy from us instead of other suppliers?

The factory was established 15 years ago, is a high-tech technology enterprise, has a professional R & D design, manufacturing, sales after-service in our factory, R&D is our most important department. We are focusing on solving marking,labeling,sorting,inspection,tracking integrated production applications.

6.How long is the delivery time?

In order to ensure the quality of products, so that customers receive high-quality laser machines. Our company has strict process of materials incoming inspection, putting in storage, materials picking, machine production, quality inspection, warehouse-out inspection. For standard machines, it would be 5-7 working days; For non-standard machines and customized machines according to client's specific requirements, it would be 15 to 30 working days.

Our factory is located in Guangdong, China and was established in 2009.

2. How can I get the best machine for me?

You can tell us your working material, detail work by picture or video so that we can judge whether our machine can meet your needs or not. Then we can give you the best machine depends on our experience.

3. This is the first time I use this kind of machine, is it easy to operate?

We will send you manual and guide video in English, it can teach you how to operate the machine. If you still can not learn how to use it, we can help you by video connection online help you.

4.What can you buy from us?

We supply laser machines and production solution. Laser machines include CO2 laser marking machine, UV laser marking machine, Optical Fiber laser marking machine. Production solution include visual positioning system, visual inspection equipment and system, anti-counterfeiting anti-channeling traceability system, production management system, quality assurance system, marketing system, etc. Laser marking machine and visual inspection equipment can be customized.

5.Why do you buy from us instead of other suppliers?

The factory was established 15 years ago, is a high-tech technology enterprise, has a professional R & D design, manufacturing, sales after-service in our factory, R&D is our most important department. We are focusing on solving marking,labeling,sorting,inspection,tracking integrated production applications.

6.How long is the delivery time?

In order to ensure the quality of products, so that customers receive high-quality laser machines. Our company has strict process of materials incoming inspection, putting in storage, materials picking, machine production, quality inspection, warehouse-out inspection. For standard machines, it would be 5-7 working days; For non-standard machines and customized machines according to client's specific requirements, it would be 15 to 30 working days.

7. Do you arrange shipment for the machines?

Yes, we have freight agents for sea shipping, air shipping. If you choose our freight agents, you just need to pay the shipping cost to us, our freight agency will arrange the shipment for you. Of course you can choose your own freight agency to arrange shipment, we will prove you the EXW price, your freight agency need to pick up the machine from our factory.

Yes, we have freight agents for sea shipping, air shipping. If you choose our freight agents, you just need to pay the shipping cost to us, our freight agency will arrange the shipment for you. Of course you can choose your own freight agency to arrange shipment, we will prove you the EXW price, your freight agency need to pick up the machine from our factory.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices