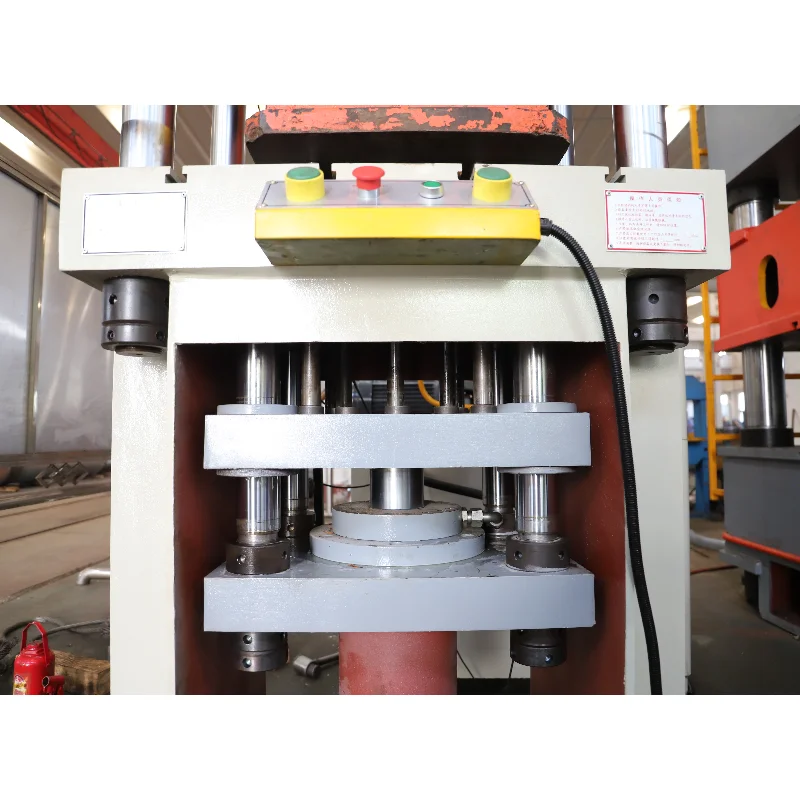

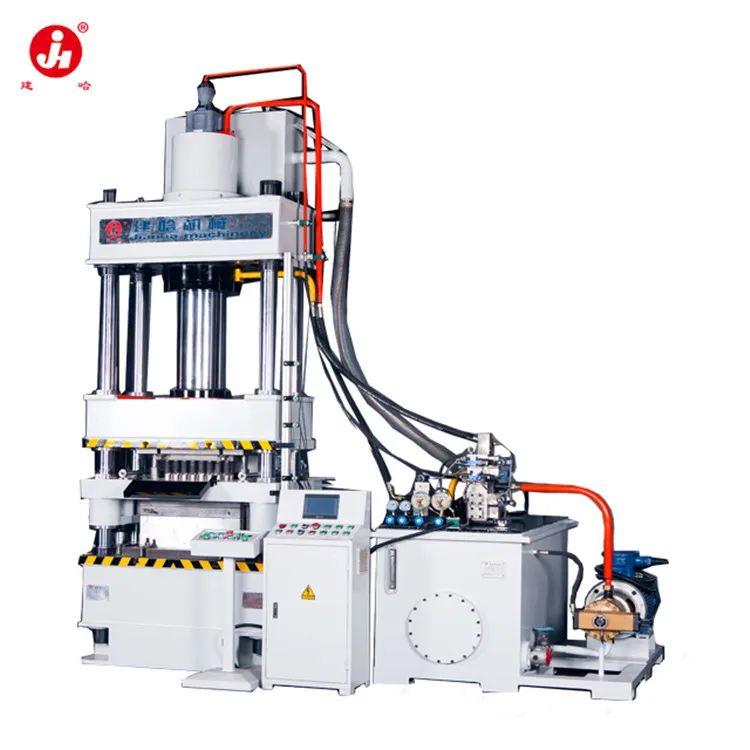

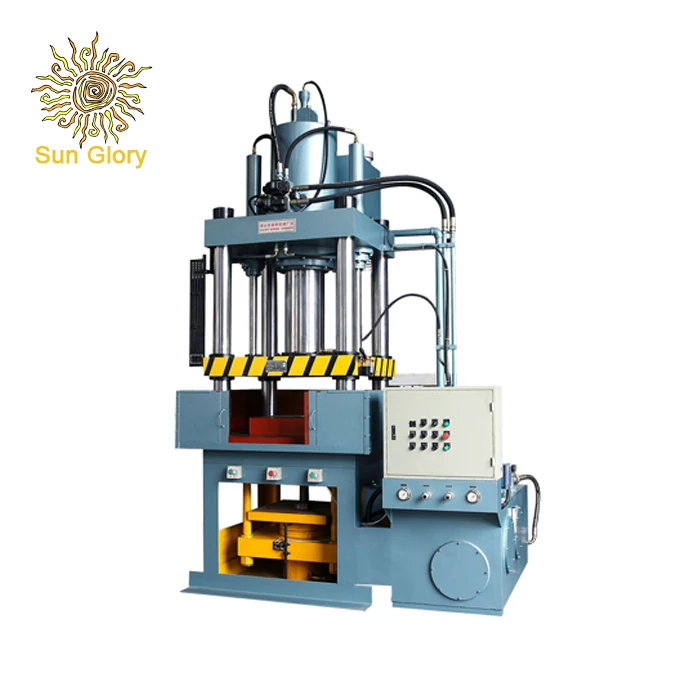

deep drawing hydraulic press machine 100 ton vertical four column hydraulic press

- Category: >>>

- Supplier: Tengzhou Dingrun Forging Machinery Plant

Share on (1601271703899):

Product Overview

Description

kitchenware,kitchensink,basin,bowl,pot Fire extinguishers, gas tanks, lunch boxes, trays, heads, floor drains, bathtubs, and other

products suitable for cold extrusion and stretch molding.etc.making machine.

transparent, standardized, fast delivery.

press machine site installation, on-site training, routine maintenance, continuous return visit, customer care.

Is it independent research and development production? We have a strong technical team and a complete modern production workshop for four columns hydraulic press,and has a number of patented technology.

support the site installation, commissioning, technical guidance,and after-sales maintenance support.

production capacity is very strong, conventional models try to ensure that the spot.

Whether to support OEM services, custom processing? you can tailor the design and provide a set of solutions.

Is the machine voltage adjustable and the pressure is adequate?

| ||||||||

We Recommend

200 Тонн гидравлический пресс универсального для порошкового формова

Square/Cylindrical Mineral Block Animal Licking Salt Block Tablet Making Machine

1000 Ton to 2000 Ton 4 Column Hydraulic Press Roof for Electric Vehicle

New Arrivals

New products from manufacturers at wholesale prices