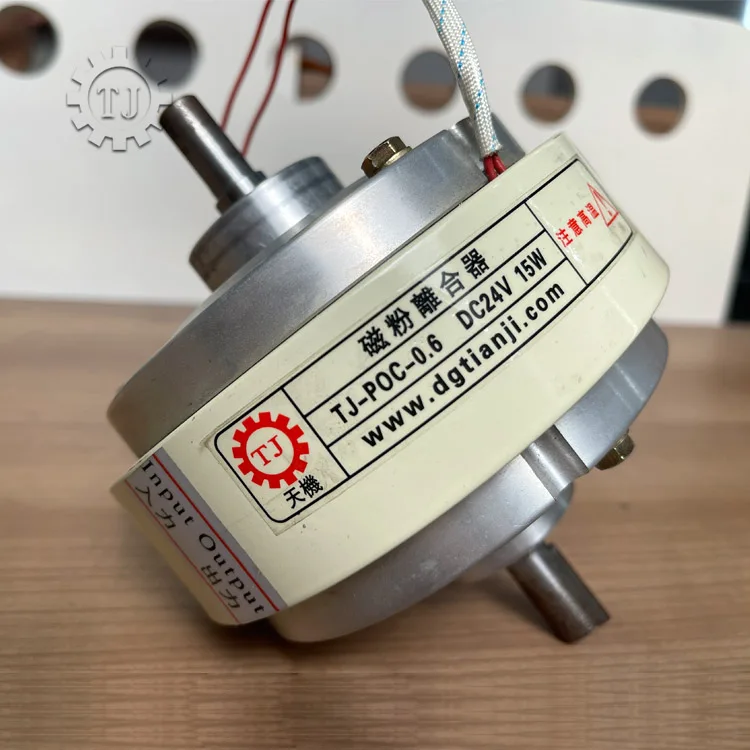

High Quality Industrial Machinery parts Micro Magnetic Powder Clutch For Slitting Machine

- Category: >>>

- Supplier: Dongguan Taiji Speed Reducer Clutch Co. Ltd.Dongguan Ltd.

Share on (1601271920900):

Product Overview

Description

Product Description

Brief introduction of magnetic powder clutch:

A magnetic powder clutch is a special type of electromagnetic clutch which does not

use friction plates. Instead, it uses a fine powder of magnetically susceptible material (typically stainless steel) to

mechanically link an otherwise free wheeling disc attached to one shaft, to a rotor attached to the other shaft. When a magnetic field is applied to the powder, it forms chains connecting the disc and rotor. The strength of the chains depends on the strength of the magnetic field. We use the finest materials available for magnetic components to yield high friction indexes, as well as premium non-asbestos linings to improve response time and extend working life. We will be reliable brake supplier for you.

use friction plates. Instead, it uses a fine powder of magnetically susceptible material (typically stainless steel) to

mechanically link an otherwise free wheeling disc attached to one shaft, to a rotor attached to the other shaft. When a magnetic field is applied to the powder, it forms chains connecting the disc and rotor. The strength of the chains depends on the strength of the magnetic field. We use the finest materials available for magnetic components to yield high friction indexes, as well as premium non-asbestos linings to improve response time and extend working life. We will be reliable brake supplier for you.

Notes

1.Don’t overload, meanwhile cool to appropriate temperature The value of the torque/rotational speed/slip power should be less than the rated value. The cooling mode(natural cooling/forced air cooling/water cooling) should depend on the maximum slip power when it works and the cooling air should pass the water and oil filter. The temperature detector and the alarm should be

installed to prevent high temperature which can affect the service life of the magnetic powder.(the highest temperature is 80 degree)

installed to prevent high temperature which can affect the service life of the magnetic powder.(the highest temperature is 80 degree)

2.Concerning the service life The life of the magnetic powder clutch and brake rely on the life of the magnetic powder. Generally speaking, its service life is 4500-7500hours in the state of non overloaded; but its service life can extend several times in some cases, such as: the working torque of the magnetic powder clutch/brake,relative slip rotational speed and slip power can be reduced to 50%-70% of the rated value. This is to say, the margin can be enlarged as soon as possible when designing.

3.Concerning the torque After the magnetic powder clutch and brake working, the magnetic powder will be in grinding at the beginning which leads to the torque decreasing slightly, but the gap can be compensated through adjustment the current..

3.Concerning the torque After the magnetic powder clutch and brake working, the magnetic powder will be in grinding at the beginning which leads to the torque decreasing slightly, but the gap can be compensated through adjustment the current..

Micro powder clutch Product Features:

(1) High-precision torque control.

(2) Superior durability, long life , portability.

(3) The stability of a fixed superior torque characteristics.

(4) Continuous operation of the use of sliding.

(5) Link sleek, non-shock.

(6) Suitable for high-frequency operation.

(7) Lightweight, maintenance-free, long life.

Application Range:

Slitting and slitting machine, compound rewinding machine, laminating machine, laminating machine, film machine, printing and dyeing machine, coating machine, printing machine, paper machine machinery, bag making machinery, paper making machinery, wire and cable machinery, winding machine , wire machinery, bale bag machinery, textile machinery, weaving machinery, woodworking machinery, test equipment, simulation load, precision tension control of various machinery.

Generally used in industrial machinery winding and unwinding devices, other general industrial machinery.

1. Fast response. Dry design means instant reaction to commands.

(1) High-precision torque control.

(2) Superior durability, long life , portability.

(3) The stability of a fixed superior torque characteristics.

(4) Continuous operation of the use of sliding.

(5) Link sleek, non-shock.

(6) Suitable for high-frequency operation.

(7) Lightweight, maintenance-free, long life.

Application Range:

Slitting and slitting machine, compound rewinding machine, laminating machine, laminating machine, film machine, printing and dyeing machine, coating machine, printing machine, paper machine machinery, bag making machinery, paper making machinery, wire and cable machinery, winding machine , wire machinery, bale bag machinery, textile machinery, weaving machinery, woodworking machinery, test equipment, simulation load, precision tension control of various machinery.

Generally used in industrial machinery winding and unwinding devices, other general industrial machinery.

1. Fast response. Dry design means instant reaction to commands.

2. Durability. Excellent heat dissipation and quality materials mean long life, even under high frequency and high performance conditions.

3. Easy to install and maintain. Sealed bearing race eliminates the need for removal of the center core. No dust brush is needed, and operation is simper and easier.

4. No adjustment of the motor. The motor is designed so that it does not need adjustment of the friction surface, and once it is installed only very minor adjustments are needed.

5. Sure motion. One-piece plate will not slip even under the strongest vibration for longer life.

6. Adjustable torque. Torque levels can be increased or decreased by changing the current, making it suitable for a variety

of applications.

of applications.

Specification

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

DongGuan TaiJi Speed Reducer Clutch company is a professional industrial transmission parts manufacturer, which headquarter in Taiwan. After many years efforts with all staffs , from general-purpse prodcuts to the new products development and now could provide different products to our clients.We always insist on the "Diligence,Honesty,Trust " in order to win constantly support from our customers and aslo establish "TianJi" Brand to the public with a good image.

FAQ

1.When can I get the quotation?

We usually quoted within 24 hours after receiving your inquiry. If you are very urgent to get the price, please call us or tell us in your email, so that we can regard your inquiry priority.

2.How should I place an order?

Please let us know the model number based on our specs for powder clutch, powder brake, air clutch, air brake, electromagnetic clutch, electromagnetic brake and safety chucks, other transmisson parts.

For air shafts,air adapter please show us your drawing, or let us know your request, and then we will provide you drawing for confirmation.

3.What’s your MOQ basis?

Normally, we don’t have MOQ request, except the customized mini clutches/brakes.

4.What about the lead time for production?

Honestly, it depends on the order quantity and the type of our products. For powder clutch, powder brake, tension controller,which is about 3-5 days. For safety chucks, air shafts which need about 15-30days.

5.What is the term of shipment ?

We can arrange with EXW, FOB, CIF…etc. You can choose the most convenient one or cost-effective way.

More concerned for our products , please do not hesitate to inquiry now!

We usually quoted within 24 hours after receiving your inquiry. If you are very urgent to get the price, please call us or tell us in your email, so that we can regard your inquiry priority.

2.How should I place an order?

Please let us know the model number based on our specs for powder clutch, powder brake, air clutch, air brake, electromagnetic clutch, electromagnetic brake and safety chucks, other transmisson parts.

For air shafts,air adapter please show us your drawing, or let us know your request, and then we will provide you drawing for confirmation.

3.What’s your MOQ basis?

Normally, we don’t have MOQ request, except the customized mini clutches/brakes.

4.What about the lead time for production?

Honestly, it depends on the order quantity and the type of our products. For powder clutch, powder brake, tension controller,which is about 3-5 days. For safety chucks, air shafts which need about 15-30days.

5.What is the term of shipment ?

We can arrange with EXW, FOB, CIF…etc. You can choose the most convenient one or cost-effective way.

More concerned for our products , please do not hesitate to inquiry now!

We Recommend

New Arrivals

New products from manufacturers at wholesale prices