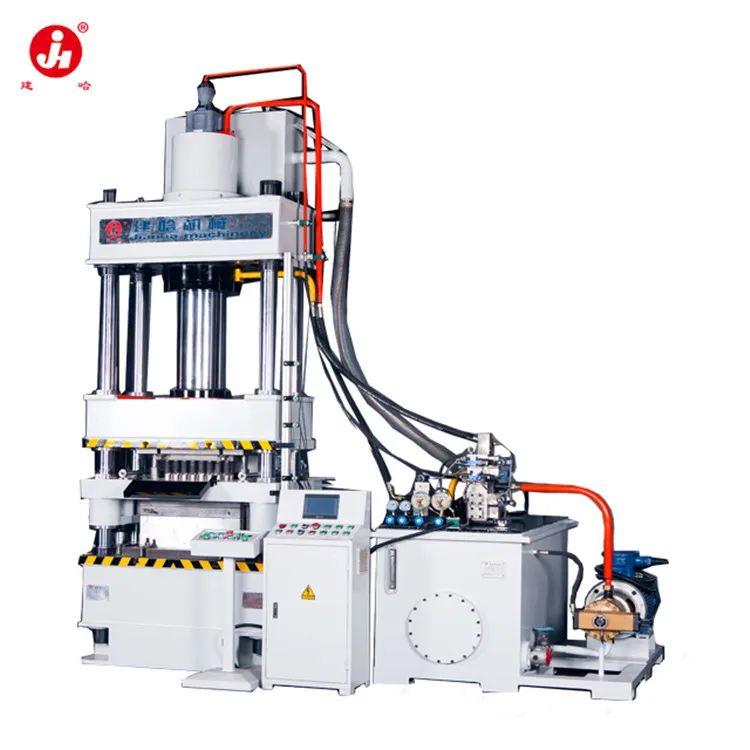

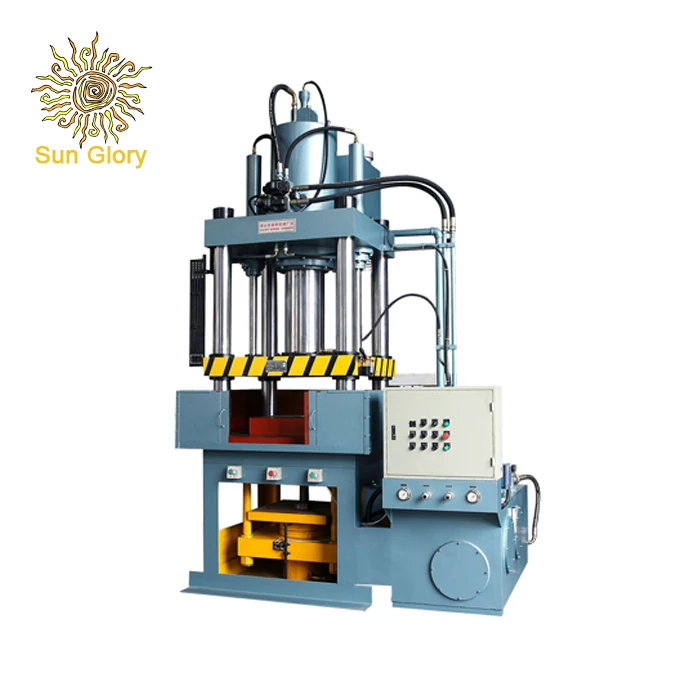

200 ton hydraulic press deep drawing hydraulic press machine automatic hot press machine

- Category: >>>

- Supplier: Tengzhou Dingrun Forging Machinery Plant

Share on (1601272061198):

Product Overview

Description

200 ton hydraulic press deep drawing hydraulic press machine automatic hot press machine

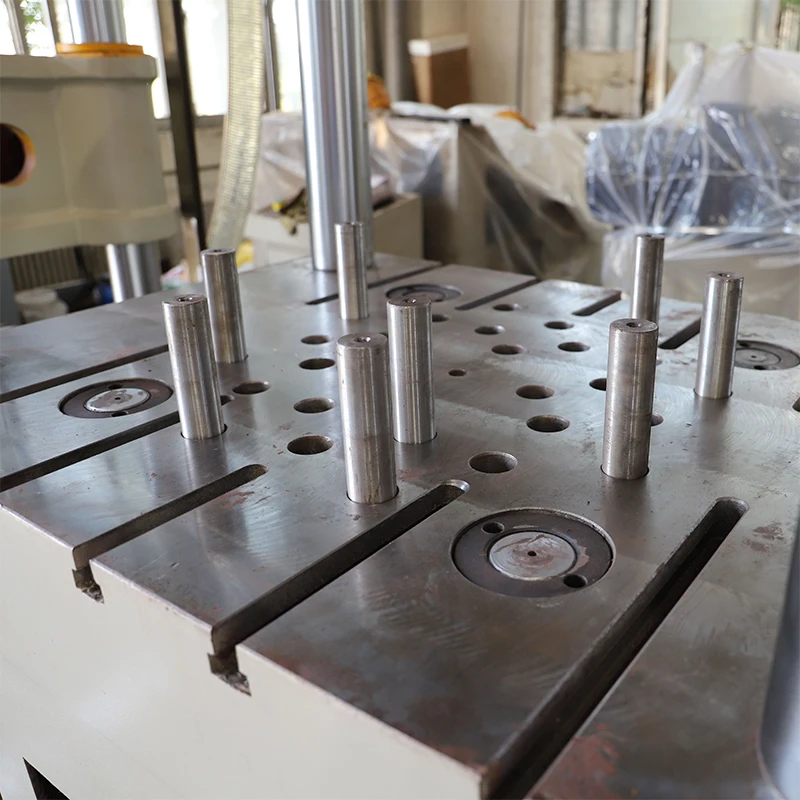

Three-beam four-column hydraulic press This series of hydraulic presses are general-purpose hydraulic presses, also known as universal hydraulic presses. It is mainly used for stretch forming, rummaging, bending and stamping of metal sheet parts, and can also be used for general pressing processes.

Specification

Project | 200t-A-K | 200t-B-K | 250t-Z |

Maximum liquid pressure (Mpa) | 25 | 25 | 25 |

Slider stroke (mm) | 400 | 500 | 400 |

Maximum opening height (mm) | 800 | 800 | 800 |

Table size (mm) | 660*660 | 660*660 | 800*800 |

Down speed of empty range (mm / S) | 30 | 100 | 32 |

Working speed (mm / S) | 6-12 | 6-12 | 6-15 |

Return speed (mm / S) | 20 | 100 | 26 |

Motor power( kw) | 7.5 | 7.5 | 11 |

Oil pump displacement (ml / R) | 40 | 40 | 40 |

Jacking force (t) | 20 | 20 | 30 |

Ejection stroke (mm) | 200 | 200 | 200 |

Approximate weight (t) | 3 | 3.4 | 3.9 |

It is suitable for thermosetting plastics (BMC/DMC, SMC), thermoplastic composites (GMT, LFT) and other fiber-reinforced plastics, composite products, and rubber products. Widely used in automobiles, building materials, ships, military industry, aerospace, locomotives, energy, electronic equipment and other industries. FRP molding hydraulic press is mainly suitable for molding of LFT-D, SMC, BMC, GMT, FRP, GRP, RTM and other thermosetting and thermoplastic materials. It is applied to the molding process of thermosetting and thermoplastic products such as parts and components in automobiles (bumpers, bottom guards, deflector ceilings, etc.), railway vehicles (high-speed train interiors), building materials/construction (cement baffles, buried pipes, etc.) and electronics/electrical fields (meter boxes, etc.).

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

Tengzhou Dingrun Forging Machinery Factory is a hydraulic machine manufacturer integrating R&D, sales and service, dedicated to four-column hydraulic presses, pull Stretching machine, forming machine, single-pipe hydraulic press, gantry hydraulic press, frame hydraulic press, 200-ton hydraulic press, 300-ton hydraulic press. 315 Ton hydraulic press, 400 ton hydraulic press, 500 ton hydraulic press, 800 ton hydraulic press, 1000 ton hydraulic press and other hydraulic machinery products. Produce The products are suitable for stretching, pressing, bending, flanging, cold extrusion, punching and other processes of metal materials. The hydraulic presses produced by our company are all One year warranty, Yisheng maintenance. The product has passed multiple certifications such as EU CE certification, and has a number of product innovation patents and honorary certificates Book. Products are exported to countries and regions such as America, Africa, Europe, Middle East and Southeast Asia

FAQ

Q:How about your machine quality?We are worry about the quality.

A:Woda is a mature brand in China. through our several years research in technology , our design including strcture and detailed sercurity and precision has enhanced greatly, and can match all the CE standard or mor strict standard.Our machines distribute worldwide to about 20 countries where there are metal plate industry.And where there are our machines, there are good reputation and terminal user satisfaction.

Q:Why Choose your company?

A:We can provide customized services according to customer requirements. We also have professional R &D team and fast response sales team. Strictly control each step of QA &QC system processes. We have an after sale service team than can quickly solve any problem you may have in the use.

Q:How to select your machine?

A: you can tell me your specifications ,we can choose the best model for you . we also have some regular model for you to

choose.You can also provide the drawings, size , photos of the products, we can design the suitable machine for you according to your requirements. After the machine is finished, you can also provide samples and we will test it for you.

A:Woda is a mature brand in China. through our several years research in technology , our design including strcture and detailed sercurity and precision has enhanced greatly, and can match all the CE standard or mor strict standard.Our machines distribute worldwide to about 20 countries where there are metal plate industry.And where there are our machines, there are good reputation and terminal user satisfaction.

Q:Why Choose your company?

A:We can provide customized services according to customer requirements. We also have professional R &D team and fast response sales team. Strictly control each step of QA &QC system processes. We have an after sale service team than can quickly solve any problem you may have in the use.

Q:How to select your machine?

A: you can tell me your specifications ,we can choose the best model for you . we also have some regular model for you to

choose.You can also provide the drawings, size , photos of the products, we can design the suitable machine for you according to your requirements. After the machine is finished, you can also provide samples and we will test it for you.

We Recommend

200 Тонн гидравлический пресс универсального для порошкового формова

$24,000.00-25,600.00

Square/Cylindrical Mineral Block Animal Licking Salt Block Tablet Making Machine

$14,000.00-16,000.00

1000 Ton to 2000 Ton 4 Column Hydraulic Press Roof for Electric Vehicle

$30,600.00-100,000.00

New Arrivals

New products from manufacturers at wholesale prices