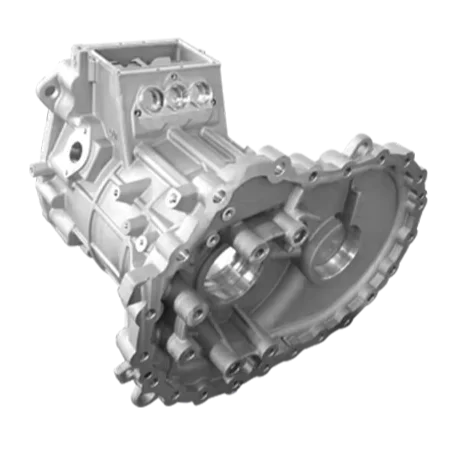

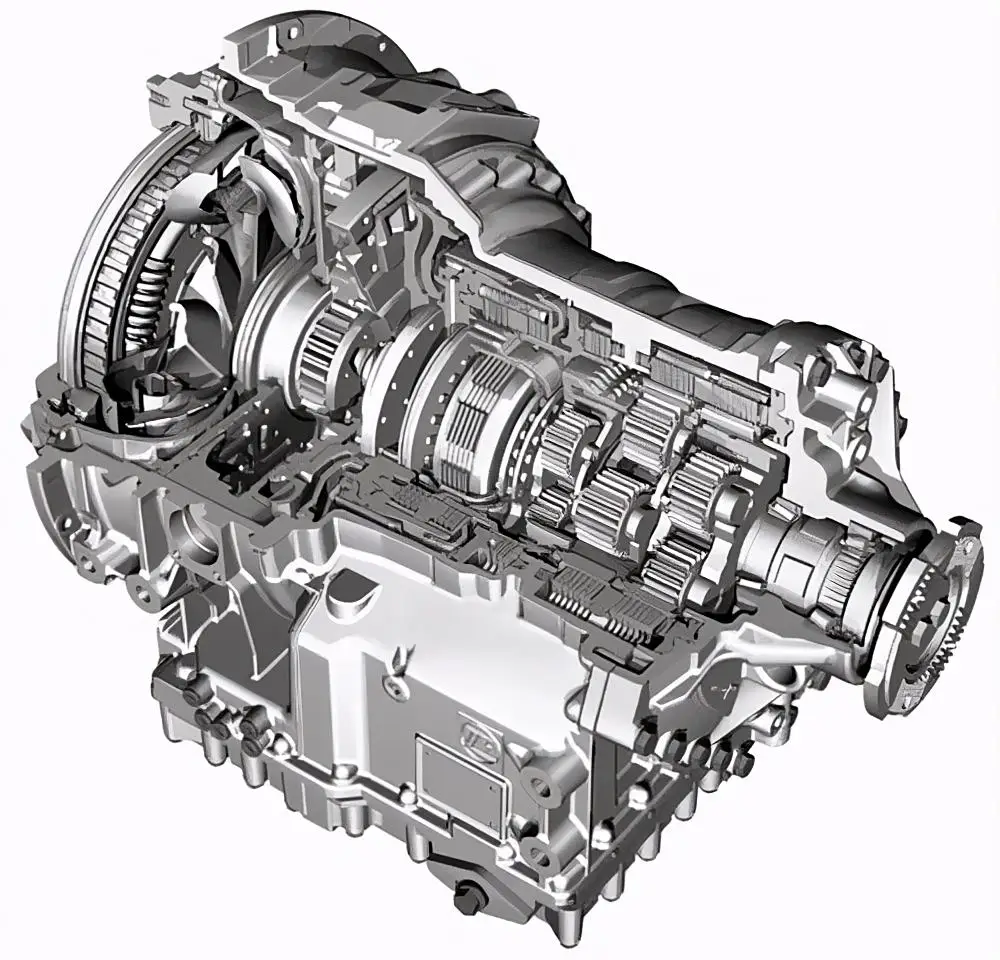

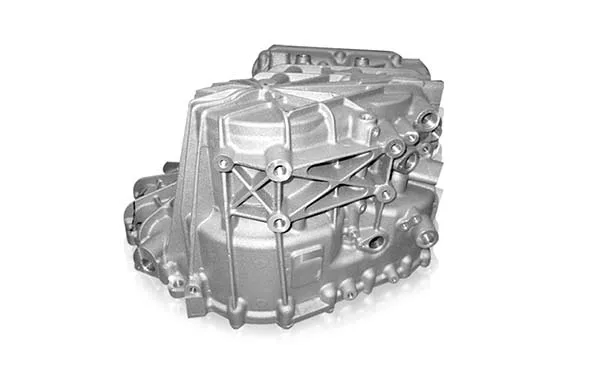

OEM High Pressure Die Casting Company Custom Precision Metal Casting Service Aluminum Die Casting Spare Part casting service

- Category: >>>

- Supplier: Suzhou Jinyun Business Technology Co. Ltd.

Share on (1601272167730):

Product Overview

Description

Customised SOP process

Customers provide drawings

Produced according to customer requirements

Quality control of products and arrangement of shipment

Products Description

Product Material | ADC12、ADC14、A380、A354、A356、ALSi10Mg、ALSi10Mg(Fe)、ALSi12Fe、ALSi8、ALSi9CU3、HA7-M |

Surface Treatment | AL melting, Die casting, Bur Removing, CNC Machining, Cleaning, Plating, Powder Coating, Assembly & 100% leakage test; |

Size | 1、 According to customers' drawings |

Drawing Format | step, dwg, igs, pdf |

Certificates | ISO 9001:2015 & IATF 16949;IEC 62321;ISO 45001;ISO 50001;ISO 14001; |

Our Equipment

Die casting production equipment | More than 60 die-casting production machine. All machines are equipped with automatic idling, automatic spraying system, automatic extractorconveyance belt system and holding furnace big tonnage m/c are equipped with ABB robot arm KUKA Spraying robot in order to improve the operating efficiency and stable quality. 180T,280T,350T,420T,500T,560T,630T,800T,1250T,1600T,2000T,2500T,4000T |

LPG / Natural Gas central melting furnaces | 8 units of LPG / Natural Gas central melting furnaces. Equipped with tool temp control unit andvacuum unit to improve products quality & stability. |

CNC Machining Center & Support | 600 sets of CNC Machine centers (consists of US HAAS VF3, Japan Fanuc T14i-Ee, Taiwan Wintec-MV45, US Akira Seiki)and 5 sets of Korea KIA, LG MAZAK HMC. |

E-Plating & Powder Painting | We have supporting suppliers specialized in powder coating and plating, including Cu, Ag. Ni, Chromating, etc. Meanwhile, we have various of powder coating and plating inspection equipments, such asimpact tester, film thickness tester, color difference tester, gloss tester, salt spray tester. These inspection tools can effectively control the quality of the products and win our customers' trust. |

Software | ANYSAST,MAGMA,PRO-E,MASTER-CAM,AUTO-CAD,SOLIDWORKS |

Main Inspection Equipments | CMM、OBLE Spectrometer、Universal Testing Machine、Metallographic Microscope、ROHS Analyzing Machine、Optical Projector、X-ray NDT Testing Machine、Brinell Hardness Tester |

Quality Policy & System | APQP、SPC、MSA、FMEA、PPAP |

Production workshop show

Die casting workshop

Die casting Tooling workshop

CNC Machining Workshop

Product Quality Inspection Workshop

Cooperating Partners

Why Choose Us

service section: | 1、24-hour manual online; 2、one service team to dock a project; 3、support small language communication; |

Technology section | seven production processes, technical support, quality inspection, mold making, die-casting production, machine production, surface treatment process, supporting facilities; |

Price section | The products are all produced in our own factories, the price is the best in the market and the best cost performance; |

Factory size | We have our own 3 production bases, Weitang auto parts casting factory, Suzhou Jincheng Precision Casting Co., Ltd., Xuzhou Jincheng Precision Manufacturing Co., Ltd., the total asset scale has exceeded 1 billion yuan, covers an area of nearly 300 acres, plant area of 180,000 square meters, with 150 ~ 4,000 tons of fully automated cold chamber die-casting island production line of 60, more than 600 sets of advanced precision machining centers and all kinds of ancillary facilities and large-scale precision measuring instruments and equipment dozens of units. Facilities and large-scale precision measuring instruments and equipment dozens of sets, with an annual output of 50,000 tons of aluminum alloy die-casting parts and components of research and development, production and precision machining capabilities; |

3D view of factory size

FAQ

Q1. Are you a factory or trade company?

We have 3 factories

No. 40, Zhentai Road, Taiping Industrial Park, Xiangcheng District, Suzhou;

No.26 ,Aigehao Road, Weitang Town, Xiangcheng District, Suzhou;

high-tech Industrial Development Zone New District, south of Qianjiang Road, west of Kunlun Road,Xuzhou;

Room 1401-1406, Building 1, Xinhuihu Business Center, No.528 Litai Road, Xiangcheng District, Suzhou, Jiangsu, China; Welcome to visit our factory.

Q2. What kind of production service do you provide?

AL melting, Die casting, Bur Removing, CNC Machining, Cleaning, Plating, Powder Coating, Assembly & 100% leakage test;

Q3. How about the lead time?

Mold: 3-5 weeks

Mass production: 3-4 weeks

Q4. How about your quality?

♦We have got ISO9001:2015 and IATF16949 certificates.

♦We will make the operation instruction once the sample is approved.

♦We will 100% inspect the products before shipment.

♦Transactions can be through Alibaba's trade assurance.

Q5. How long should we take for a quotation?

After receiving detailed information(your 2D/3D drawings or samples), we will quote you within 2 days.

Q6. What is your quotation element?

Drawings or Sample, Material, Finish, and Quantity.

We have 3 factories

No. 40, Zhentai Road, Taiping Industrial Park, Xiangcheng District, Suzhou;

No.26 ,Aigehao Road, Weitang Town, Xiangcheng District, Suzhou;

high-tech Industrial Development Zone New District, south of Qianjiang Road, west of Kunlun Road,Xuzhou;

Room 1401-1406, Building 1, Xinhuihu Business Center, No.528 Litai Road, Xiangcheng District, Suzhou, Jiangsu, China; Welcome to visit our factory.

Q2. What kind of production service do you provide?

AL melting, Die casting, Bur Removing, CNC Machining, Cleaning, Plating, Powder Coating, Assembly & 100% leakage test;

Q3. How about the lead time?

Mold: 3-5 weeks

Mass production: 3-4 weeks

Q4. How about your quality?

♦We have got ISO9001:2015 and IATF16949 certificates.

♦We will make the operation instruction once the sample is approved.

♦We will 100% inspect the products before shipment.

♦Transactions can be through Alibaba's trade assurance.

Q5. How long should we take for a quotation?

After receiving detailed information(your 2D/3D drawings or samples), we will quote you within 2 days.

Q6. What is your quotation element?

Drawings or Sample, Material, Finish, and Quantity.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices