Manufacturers Supply Green Silicon Carbide Micro Powder For Reaction Sintering Silicon Carbide Ceramic Products

- Category: >>>

- Supplier: Henan Dahua New Material Co. Ltd.

Share on (1601272525111):

Product Overview

Description

Products Description

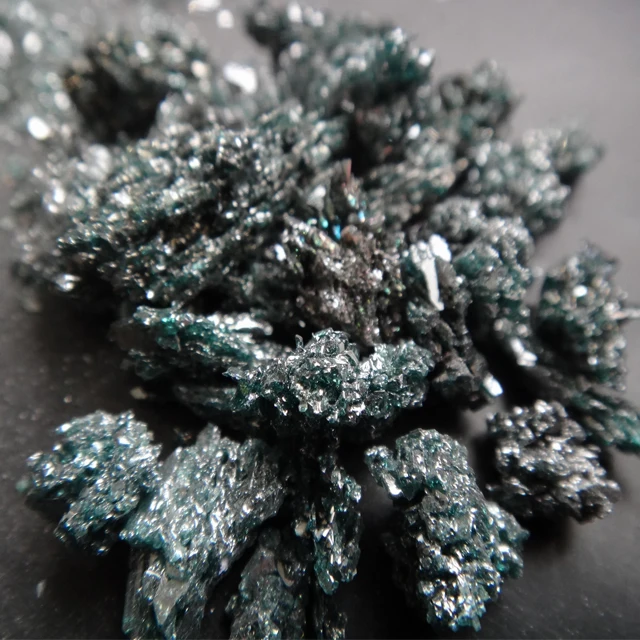

The production method of green silicon carbide powder is basically the same as that of black silicon carbide, but the requirements for raw materials are different. Green silicon carbide is made of petroleum coke and high-quality silica as the main raw materials, and salt is added as an additive. It is smelted by resistance furnace at high temperature. The crystallized crystal has high purity and high hardness, and its hardness is between corundum and diamond.

The preparation method of green silicon carbide can be divided into two kinds

Green silicon carbide powder has stable properties, mainly used in reactive sintering, non-pressure sintering, recrystallization sintering, metal anti-corrosion surface spraying, locomotive braking device, honeycomb ceramics, silicon carbon rod new technology and other fields. Our company produces F240, F1200, W20, W14, 90#,150# and other reaction sintered ceramics special silicon carbide powder, mainly used in the field of silicon carbide products grouting molding, extrusion molding, good fluidity, high purity, good particle shape, reasonable particle size distribution, bulk density, well received by customers!

Product model

Specification

item | value |

SiC | 99.35% |

Fe2O3 | 0.03% |

SiO2 | 0.10% |

F.C | 0.07% |

PH | 7.0 |

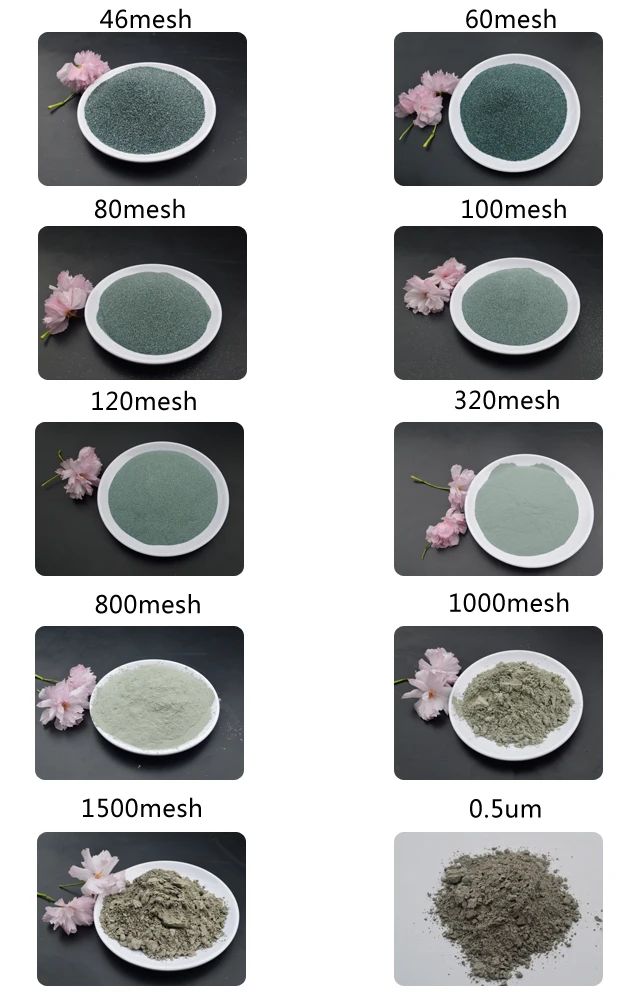

Model number | F46 F60 F80 F90 F100 F150 F220 W28 W20 W14 W7 W5 W1.5 W0.5 |

Product application

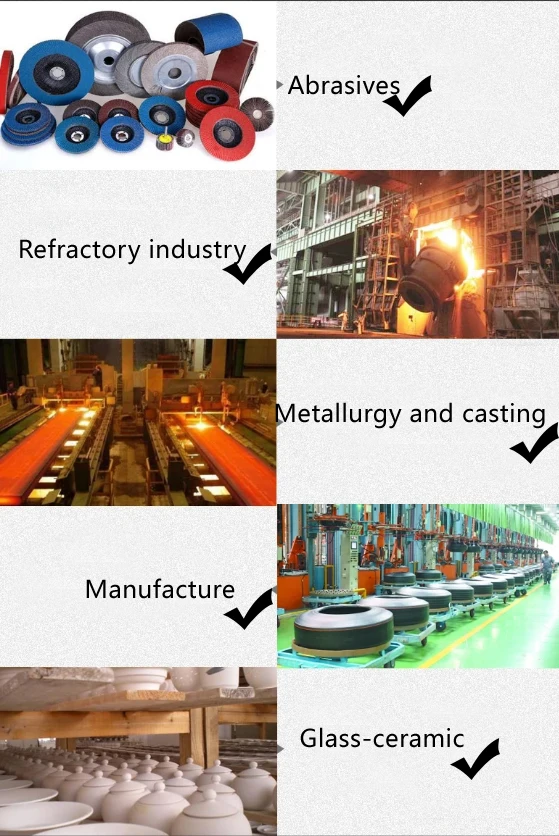

Abrasive tools. Green silicon carbide is used to manufacture abrasive abrasives such as grinding wheels, sandpaper, sand belts,whetstones, grinding blocks, grinding heads and grinding pastes. These products play a key role in the processing of metal and non-metal materials, such as the cutting and finishing of wafers in the semiconductor, solar photovoltaic industry, piezoelectric crystal industry and other fields.

Functional ceramics. Green silicon carbide because of its high thermal conductivity, high thermal strength and good heat resistance, is used to manufacture sheet kiln furniture, this material has a wide range of applications in the ceramic industry,such as in the baking and sintering process of ceramic glaze as an ideal indirect material.

Metallurgical dressing. Green silicon carbide because of its high hardness and wear resistance, is used as a wear-resistant pipe,bucket lining and other materials, its wear resistance even exceeds cast iron and rubber, so it is also used in aviation runwayand other occasions.

Refractory and corrosion-resistant materials. Green silicon carbide because of its high temperature and corrosion resistance, is usde in the production of high temperature silicon carbon rod heating element, far infrared source substrate and so on.

Other applications. Green silicon carbide can also be used to make silicon carbon rods for electric heating elements, as well as for honing cylinder liners and fine grinding high-speed steel tools.

Functional ceramics. Green silicon carbide because of its high thermal conductivity, high thermal strength and good heat resistance, is used to manufacture sheet kiln furniture, this material has a wide range of applications in the ceramic industry,such as in the baking and sintering process of ceramic glaze as an ideal indirect material.

Metallurgical dressing. Green silicon carbide because of its high hardness and wear resistance, is used as a wear-resistant pipe,bucket lining and other materials, its wear resistance even exceeds cast iron and rubber, so it is also used in aviation runwayand other occasions.

Refractory and corrosion-resistant materials. Green silicon carbide because of its high temperature and corrosion resistance, is usde in the production of high temperature silicon carbon rod heating element, far infrared source substrate and so on.

Other applications. Green silicon carbide can also be used to make silicon carbon rods for electric heating elements, as well as for honing cylinder liners and fine grinding high-speed steel tools.

Company Profile

Henan Dahua New Materials Co., LTD., specializing in the production of white corundum sand, particle size sand, white corundum powder, brown corundum, silicon carbide, silicon carbide powder, high aluminum ceramic ball, plate corundum, fused spinel,sintered spinel, fused mullite, reduced iron powder, chromium iron ore and other high-grade abrasives and refractory materials of modern enterprises, now has a fully automatic intelligent control dumping furnace, With an annual output of thousands of tons of high-quality corundum and refractory materials, located in Xingyang City, Henan Province, the company adheres to the development strategy of "science and technology Xing factory", advanced production equipment, strong technical force, complete testing equipment, stable product quality, and the ability to independently develop and produce new products in the industry. The company's quality assurance system is perfect, strict implementation of ISO9001 standards, product performance is stable, safe and reliable. The company vigorously introduce advanced professional production equipment and automatic production line, manufacturing by the majority of customers benefit products, we with stable quality, first-class service, reasonable prices, welcome domestic and foreign merchants to the factory to negotiate benefit products.

Certifications

Product packaging

Packaging can be customized according to customer requirement.

FAQ

1. How long is the delivery time?

Delivery time is determined by specific quantity.

2. How about the product quality?

The company strictly controls the quality of products, strict inspection of products before shipment.

3. What is the minimum order quantity?

Any amount is fine.

4. How about after-sales service?

We provide after-sales service, if it is confirmed that the problem is ours, we provide the appropriate after-sales service.

5. What are the advantages of the product?

Applicable to a variety of scenarios, simple operation, wide range of application.

Platform price is the reference price, the actual transaction price contact customer service consultation.

Delivery time is determined by specific quantity.

2. How about the product quality?

The company strictly controls the quality of products, strict inspection of products before shipment.

3. What is the minimum order quantity?

Any amount is fine.

4. How about after-sales service?

We provide after-sales service, if it is confirmed that the problem is ours, we provide the appropriate after-sales service.

5. What are the advantages of the product?

Applicable to a variety of scenarios, simple operation, wide range of application.

Platform price is the reference price, the actual transaction price contact customer service consultation.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices