Top Grade DN60 MO Melting Electrode Rod Pure Smooth Moly Melting Electrode Rod For Petrochemical

- Category: >>>

- Supplier: Wobo Industrial Group Corp.

Share on (1601272623234):

Product Overview

Description

High-Performance Molybdenum Electrodes: Durability and Precision for Industrial Applications

Top Quality 99.95% Moly Eletrode High Melting Point Molybdenum Eletrode For Glass Oven

Products Description

Our Molybdenum Electrodes offer unmatched performance in high-temperature environments. With their excellent thermal and electrical conductivity, these electrodes ensure efficient and precise industrial operations. Built for longevity, they resist wear and oxidation, making them ideal for glass melting, steel manufacturing, and other demanding processes.

Crafted from high-purity molybdenum, these electrodes are engineered to withstand extreme temperatures, up to 2,623°C (4,753°F), without losing their structural integrity. Their high melting point and low thermal expansion properties reduce the risk of deformation, even under intense heat. Available in various sizes and custom specifications, our molybdenum electrodes deliver consistent and reliable results across a range of industrial applications, including the glass, electronics, and metallurgy sectors.

Product Parameters

Molybdenum electrodes are widely used in various industrial applications due to their excellent electrical conductivity, high melting point, and resistance to corrosion. Here are some key parameters and properties of molybdenum electrodes:

Product Name | Molybdenum Eletrode |

Melting Point | 2,623°C (4,753°F) |

Density | 10.2 g/cm³ |

Thermal Conductivity | 138 W/mK |

Diameter | 2-150mm |

Length | Available upon request |

Product Advantage

1. High Melting Point: Withstands extreme temperatures, ensuring longevity in high-heat environments.

* Benefit:Reduced replacement frequency, leading to cost savings.

2. Superior Conductivity: Excellent electrical and thermal conductivity for efficient energy transfer.

* Benefit:Boosts process efficiency and performance.

3. Corrosion Resistance: Exceptional resistance to chemical corrosion and oxidation.

* Benefit:Ensures durability even in harsh conditions, maintaining consistent quality.

4. Low Thermal Expansion: Minimal dimensional change when exposed to high temperatures.

* Benefit:Maintains precision and stability in critical applications.

5. Customizable Sizes: Available in standard and custom dimensions.

* Benefit:Tailored to meet specific industrial requirements, enhancing versatility.

Customer Reviews

James P., Glass Manufacturer

"These molybdenum electrodes have significantly improved our glass melting operations. Thedurability and thermal conductivity are second to none!"

Lisa T., Metallurgical Engineer

"We switched to these electrodes in our steel plant and noticed immediate improvements in efficiency and cost savings."

Relative Products

Molybdenum Tube

Molybdenum Special Shape

Molybdenum Crucible

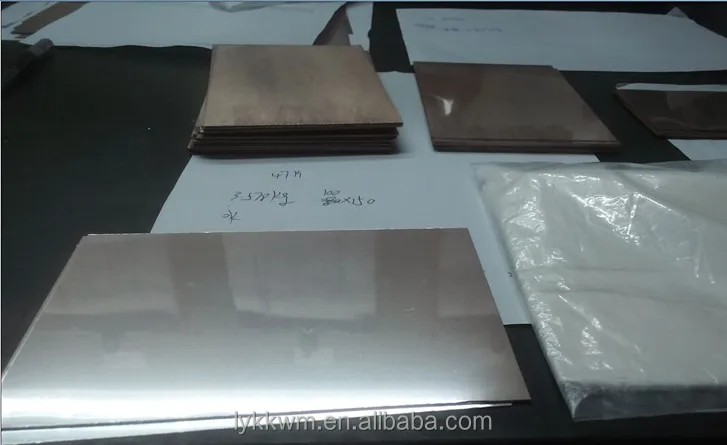

Molybdenum Copper Alloy

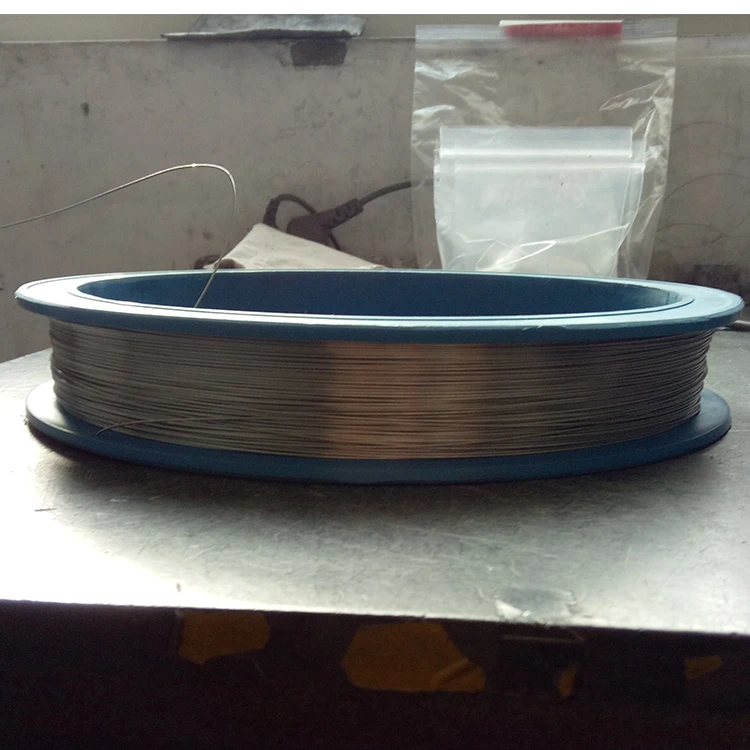

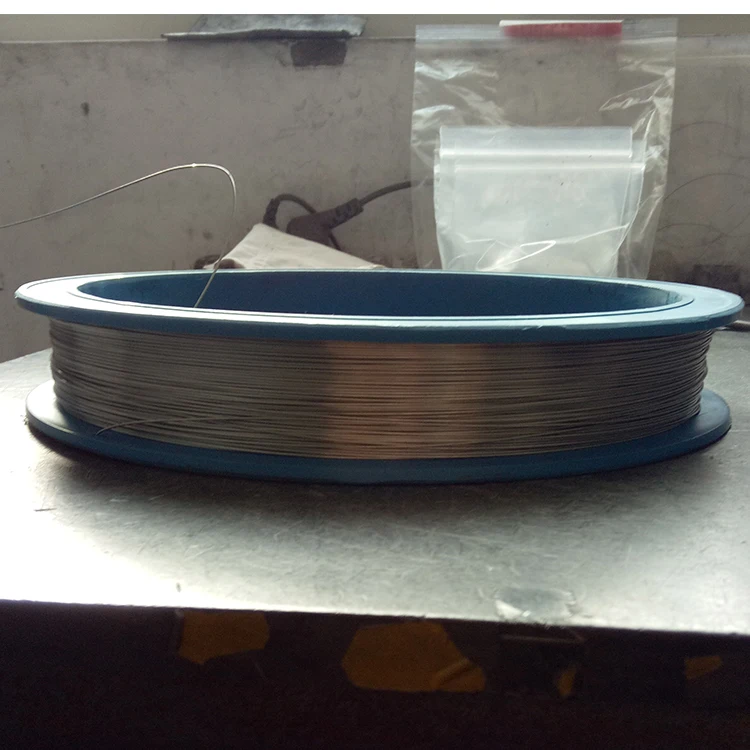

Molybdenum Wire

Molybdenum Target Material

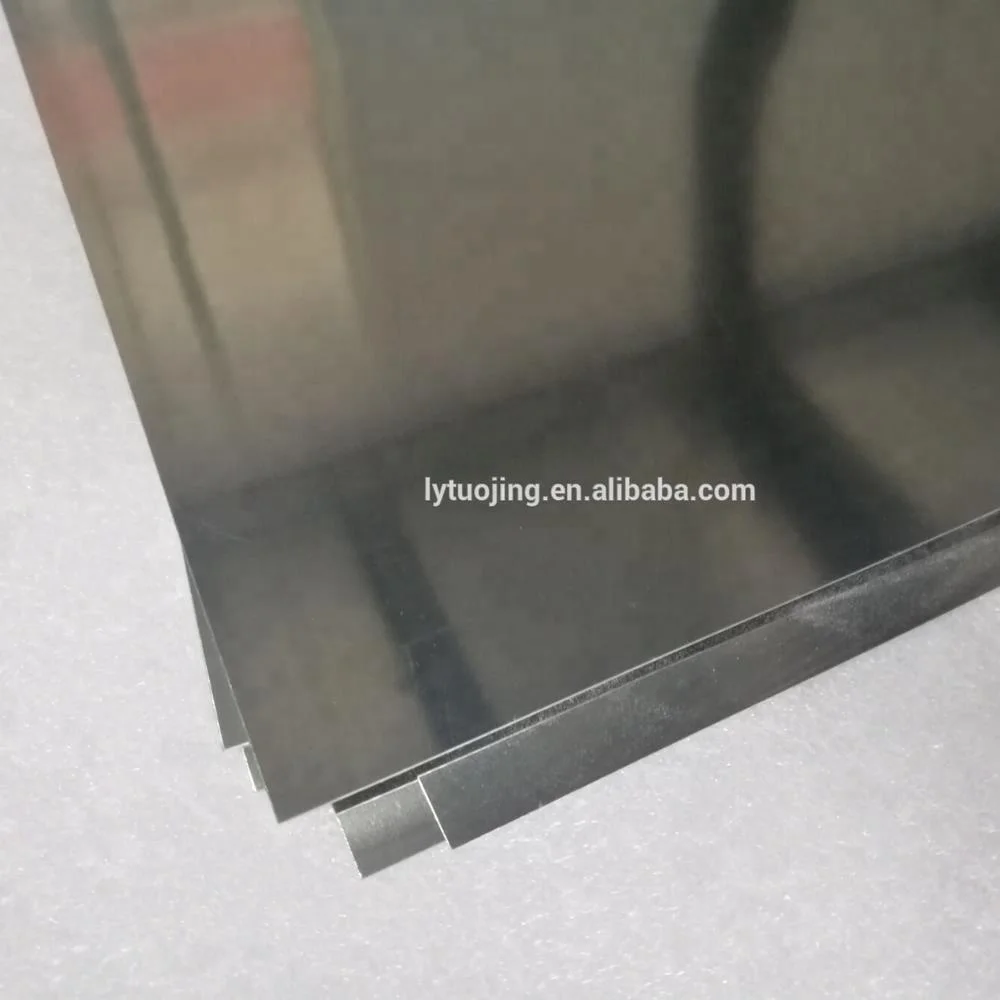

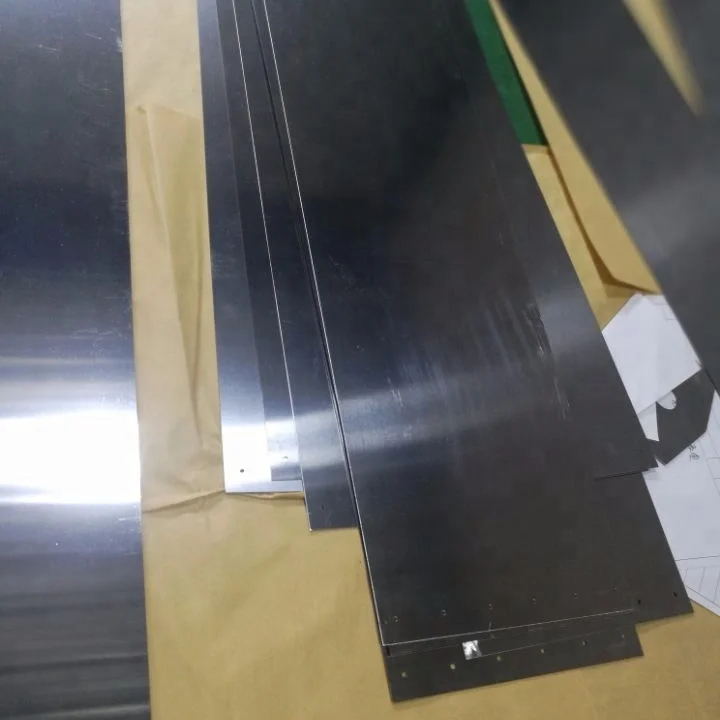

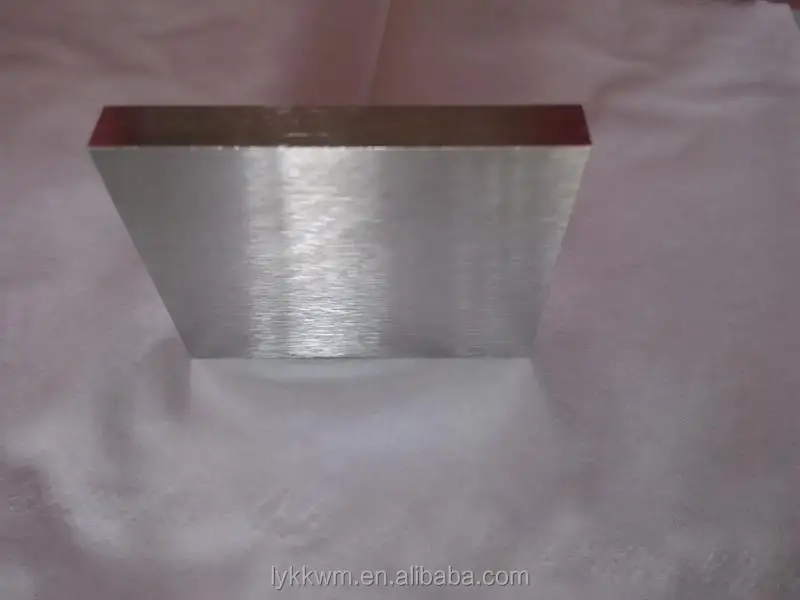

Molybdenum Sheet

Molybdenum Rod

Molybdenum Nut

Molybdenum Foil

Molybdenum Heater

Molybdenum Evaporating Boat

Molybdenum Bar

Molybdenum Sinter Boat

Molybdenum Screw

Product Application

Molybdenum electrodes are used in a variety of industrial applications due to their unique properties. Here are some key application areas:

Glass Melting

Welding

Electronics

Electrochemical

Lighting

Medical Equipment

Company Profile

Wobo's products cover the fields of new energy, energy, metallurgy, petrochemical, electronics, food, machinery, building materials, medicine, new materials, petrochemical, chemical fiber, heat treatment, glass, national defense and aerospace, and are sold to more than 100 countries and regions.

We strive to provide products with the highest quality and service, and complete with the highest standards. All our products have undergone rigorous testing, and now we have obtained CE, ISO, ASME . Our goal is 100% customer satisfaction, we will provide high-quality products and value-added services.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices