Customized 15K ultrasonic steel mold booster and horn ultrasonic plastic welder mold

- Category: >>>

- Supplier: Wuxi Marcia Technology Co. Ltd.

Share on (1601273459631):

Product Overview

Description

Company Profile

Ultrasonic Welding Tool manufacturer

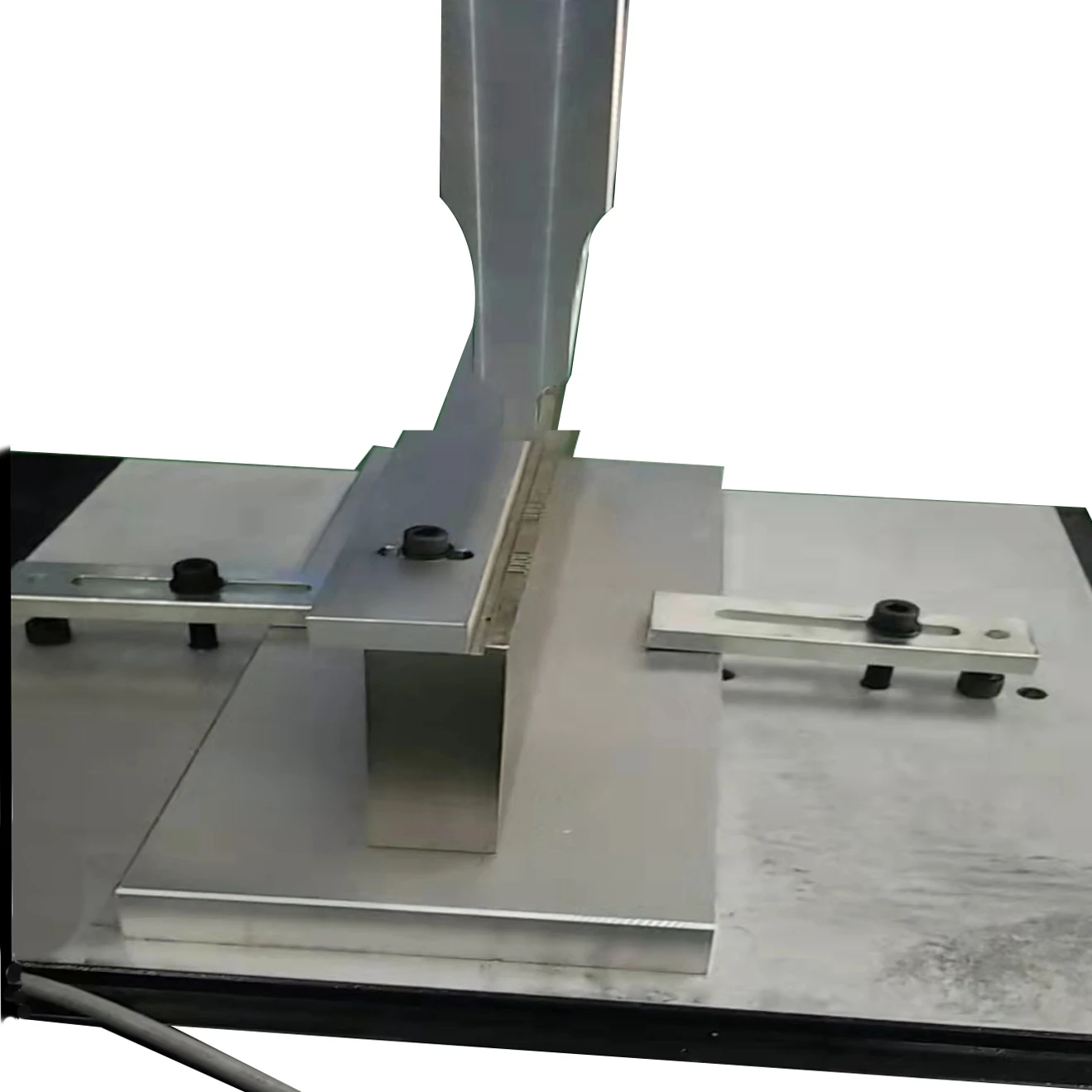

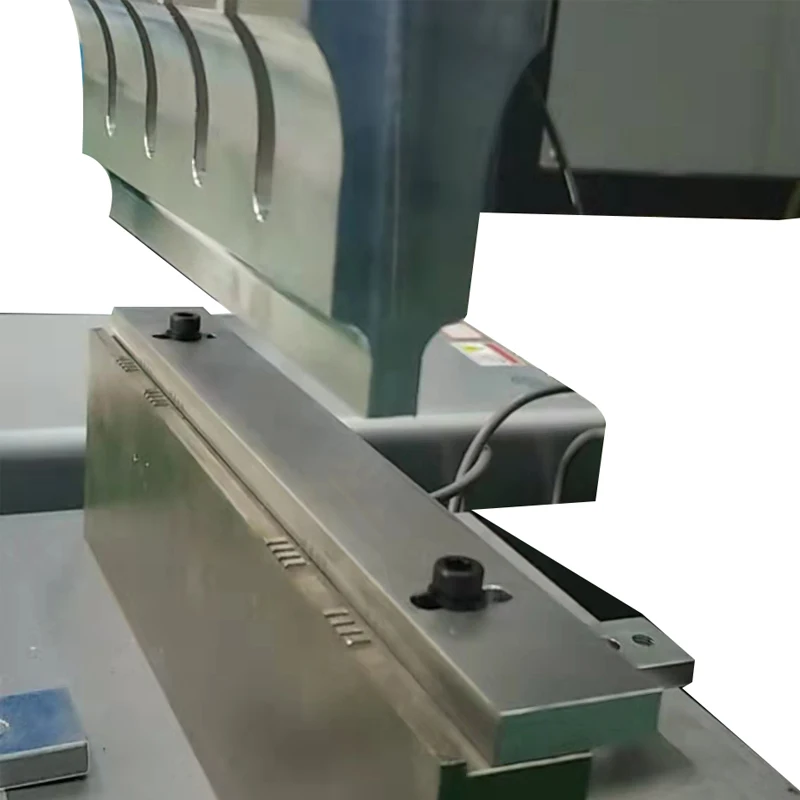

Ultrasonic mold needs different mold heads for different welding objects, whether it is near field welding or transmission welding, it needs mold heads to achieve welding effect of welding end faces.

Design of ultrasonic molds are not simple as its shape. Improper use of the mold and processing or untuned welding head, will bring expensive losses to your production it will destroy the welding effect, or even more serious will directly lead to the damage of the transducer or generator.

CNC machining center for Ultrasonic welding horn

The main products supply range including plastic welding equipment, such as hot melt welding equipment, high frequency welding equipment, ultrasonic welding equipment; customization services including welding mold tooling customization, bottle mold customization, mold core mold cavity thread and other molding parts customization, as well as related plastic.

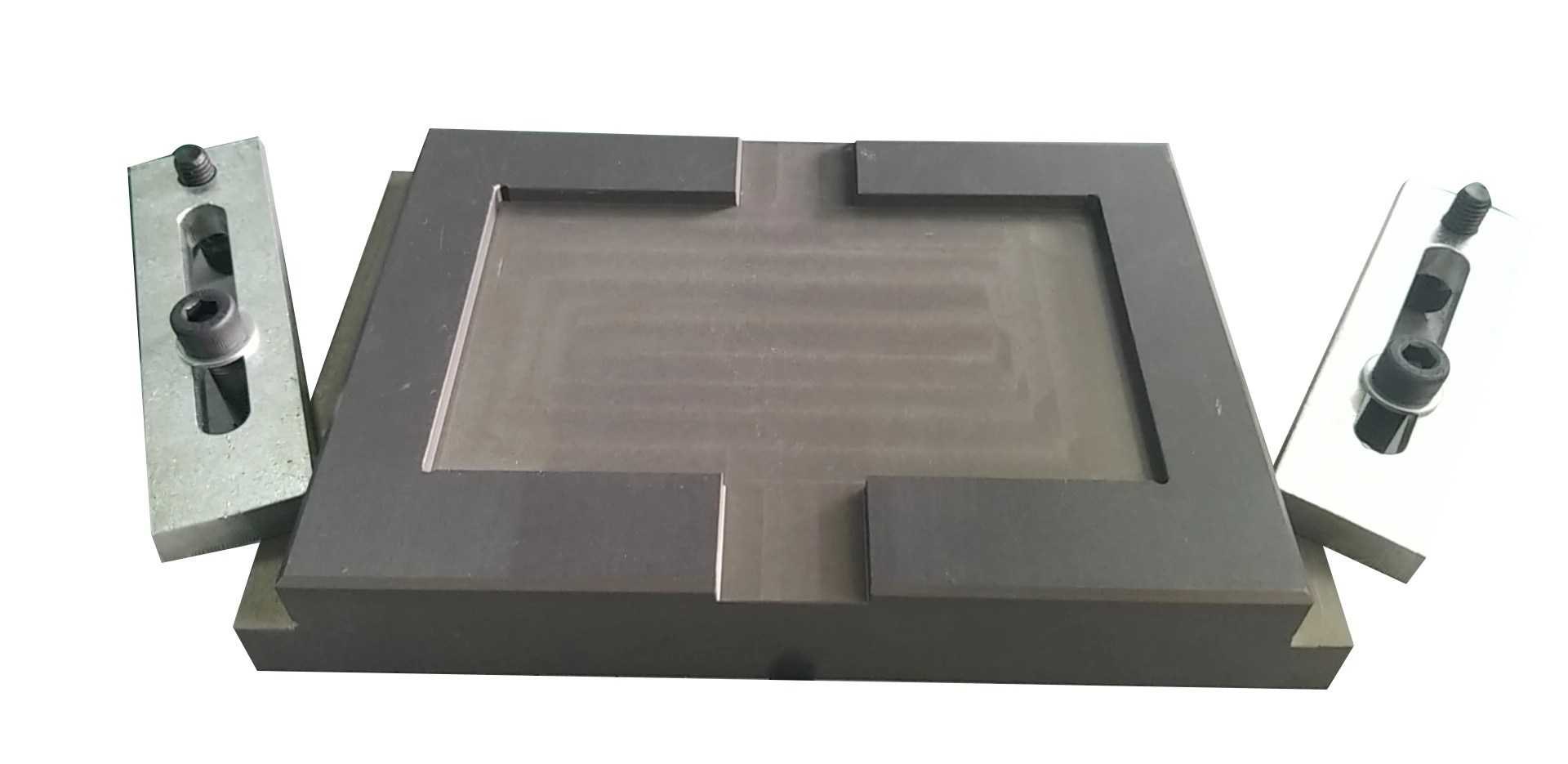

Details Images

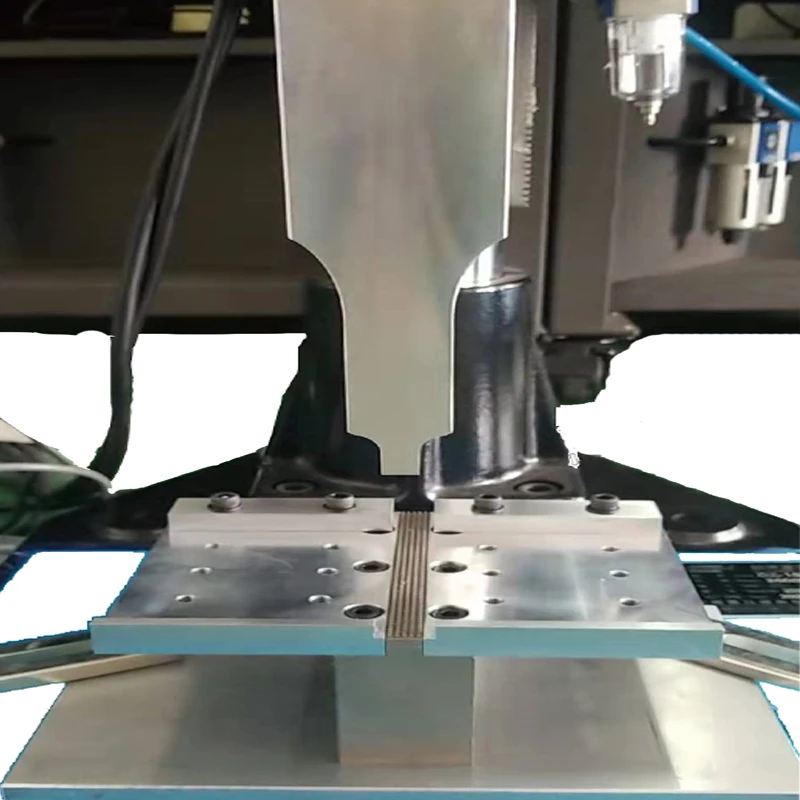

Each set of welding head and mold Produced by us , whether standard products, or customized according to customer requirements, are made of original materials, at the same time after repeated testing of welding head shape strength and audio and other parameters after many tests, can meet strict standard requirements, so that the welding head and mold match well.

Products Description

20Khz | paper cup ultrasonic welding machine |

20khz 15khz | face mask machine; plastic welding machine |

28khz | portable plastic spot welder |

35khz | portable plastic spot welder |

18khz | non-woven fabric welding machine, ultrasonic lacing machine |

20khz | PSA plastic slabs welding machine |

Product packaging

Recommend Products

Ultrasonic Mold Application Range

I: Automobile: ultrasonic wave can be controlled by computer program to implement the welding of large and irregular parts such as: bumper, front and back doors, lamps, brake lights, etc

II: Home appliances: The appropriate adjustment can be used for portable solar lamp shade, steam ironing door TV shell power rectifier TV shell screw fixed seat fly swatter washing machine take off the sink and other household appliances that need to be sealed firmly and beautiful

III : Packing: tube sealing, special packing belt connection

IV : Other commercial use: from communication equipment, computer industry printing equipment to memory products, etc.

II: Home appliances: The appropriate adjustment can be used for portable solar lamp shade, steam ironing door TV shell power rectifier TV shell screw fixed seat fly swatter washing machine take off the sink and other household appliances that need to be sealed firmly and beautiful

III : Packing: tube sealing, special packing belt connection

IV : Other commercial use: from communication equipment, computer industry printing equipment to memory products, etc.

FAQ

How can I make the correct welding mold for replacement work against the existing welding machine?

1. Concerning the welding horn, please make sure the ultrasonic frequency first ,20khz or 15khz.

Then measure the welding zone dimension ,namely length by width. Last one is to measure the installation screw size .

Then measure the welding zone dimension ,namely length by width. Last one is to measure the installation screw size .

2 ,refer to the welding roller , it is better to supply the relation drawing , if it is impossible .

Please show us your final product welding shape , and please measure the shaft end dimension which is necessary .

Please show us your final product welding shape , and please measure the shaft end dimension which is necessary .

How about the procedure after getting your order?

1. Around 5 business days for us to make the machine against your order.

2. Related testing video , machine pictures are sent to you before packing

3. Packing procedure pictures for you

4. Arrange the shipping for you, and keep you informed the tracking number

5 .Our technical support service member will be engaged for the coming set up job and guide you to run the machine smoothly .

Technical support from us not only limited by email communication ,as well as the instant messages, video chatting .

we will create a service group for your side as whatsapp ,messengers, wechat etc.

6.Periodical following up for machine operation

2. Related testing video , machine pictures are sent to you before packing

3. Packing procedure pictures for you

4. Arrange the shipping for you, and keep you informed the tracking number

5 .Our technical support service member will be engaged for the coming set up job and guide you to run the machine smoothly .

Technical support from us not only limited by email communication ,as well as the instant messages, video chatting .

we will create a service group for your side as whatsapp ,messengers, wechat etc.

6.Periodical following up for machine operation

How about the preparation work for running an ultrasonic welding machine ?

1, Ultrasonic welding machine comes with 220 Volt.(Please check your power supply, sometimes

2, transformer is needed)

3, An air compressor is needed

4, A hose which will connect the machine and air compressor.

Namely ,Ultrasonic welding machine a hose an air compressor

5,Tips about the hose:

Please make sure the air hose of welding machine first , If the hose of your air compressor different, please just add an adapter to join the two different hoses.

2, transformer is needed)

3, An air compressor is needed

4, A hose which will connect the machine and air compressor.

Namely ,Ultrasonic welding machine a hose an air compressor

5,Tips about the hose:

Please make sure the air hose of welding machine first , If the hose of your air compressor different, please just add an adapter to join the two different hoses.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices