Ultra High Pressure Mechanical Water Heat Exchanger Tube Cleaning Equipment Machine, 40k PSI

- Category: >>>

- Supplier: Jiangsu Fedjetting Tech Co. Ltd

Share on (1601273982929):

Product Overview

Description

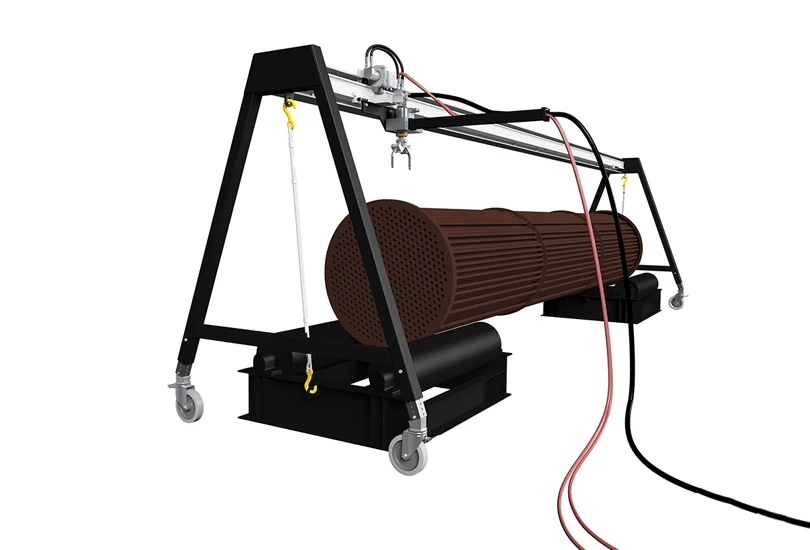

Heat Exchanger Cleaning Equipment

Fedjetting Hydro Blasting Machine

Durable I-beam structure, can withstand about 500lbs, jet reaction force, minimize deviation

Adjustable frame height: "A" frame height can be adjusted from 5-9 ft (1.5-2.7m) to adjust the optimal jet target distance according to the tube bundle size and reduce the loss of jet impact force

Adjustable frame height: "A" frame height can be adjusted from 5-9 ft (1.5-2.7m) to adjust the optimal jet target distance according to the tube bundle size and reduce the loss of jet impact force

Products Insight

The Bundle Blaster system offers a powerful and affordable automated solution for external cleaning of heat exchangers, evaporators, condensers, and other industrial tube bundles. This system is ideal for contractors and plants interested in low maintenance, cost-effective, easy-to-use equipment. The Bundle Blaster is safer and more effective than traditional hand-held methods of shell side cleaning, and 1/3 of the cost of trailer mounted systems.

Features

1. High mobility and easy transportation

2. Various cleaning head types, please choose a concentrated impact nozzle or a large area coverage nozzle according to the project requirements

3. Standard lengths are 24 ft (7.3m) and 36 ft (11m) Adjustable "A" frame with built-in locking wheel and anchor hook

4. Compatible with various pressure and flow levels to maximize cleaning efficiency

5. Easy adjustment of automatic limit devices to match stroke length and tube bundle length for continuous and efficient operation

6. Remote control panel to independently adjust speed and linear speed

7. Modular assembly structure for easy disassembly and transportation

8. Optional use of rollers to rotate the entire cleaning tube bundle for comprehensive cleaning of the outer surface of the tube bundle

9. Simple maintenance and low cost

2. Various cleaning head types, please choose a concentrated impact nozzle or a large area coverage nozzle according to the project requirements

3. Standard lengths are 24 ft (7.3m) and 36 ft (11m) Adjustable "A" frame with built-in locking wheel and anchor hook

4. Compatible with various pressure and flow levels to maximize cleaning efficiency

5. Easy adjustment of automatic limit devices to match stroke length and tube bundle length for continuous and efficient operation

6. Remote control panel to independently adjust speed and linear speed

7. Modular assembly structure for easy disassembly and transportation

8. Optional use of rollers to rotate the entire cleaning tube bundle for comprehensive cleaning of the outer surface of the tube bundle

9. Simple maintenance and low cost

Application

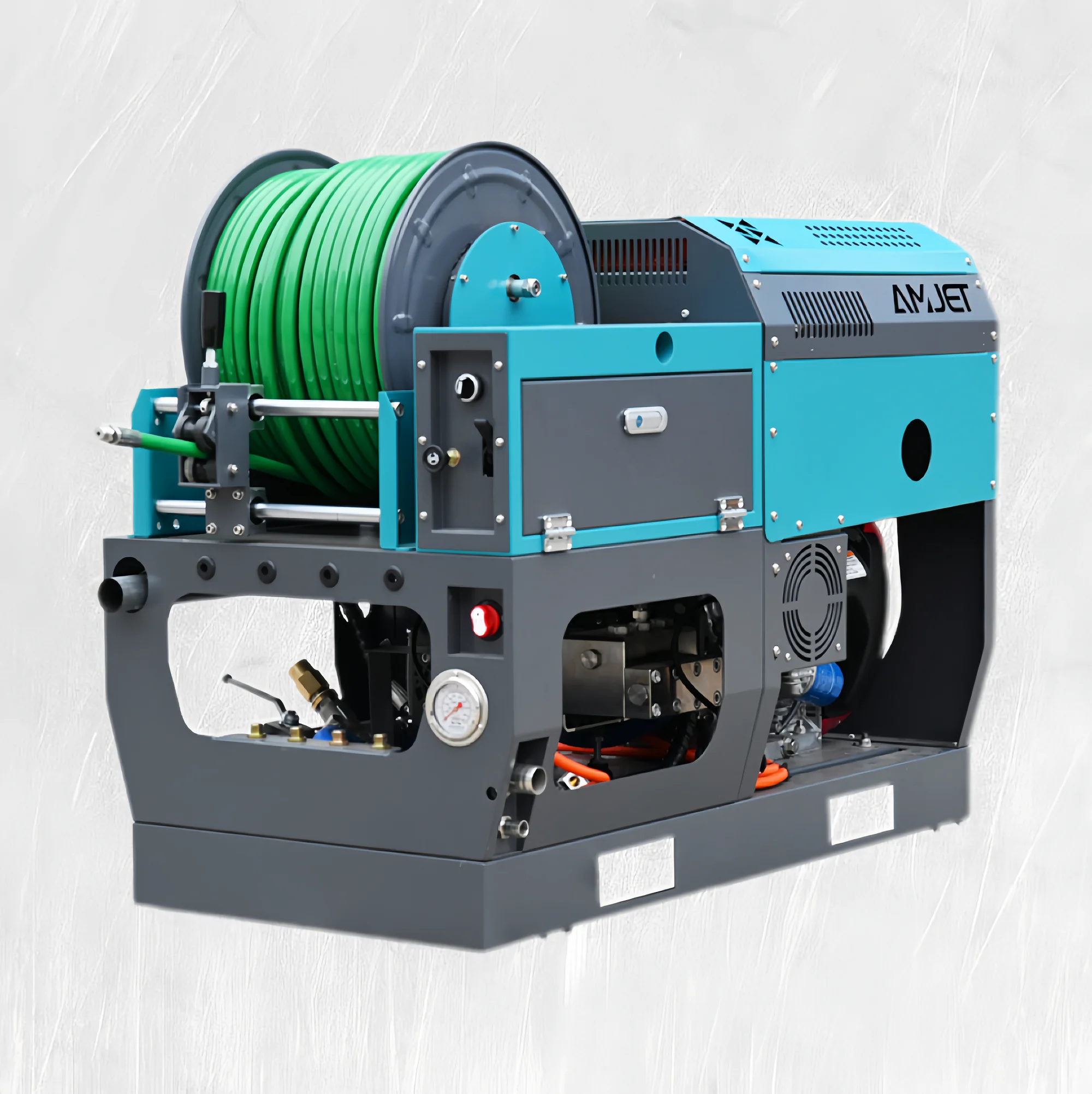

About Fedjetting UHP Hydro Blaster/UHP Water Blaster System

We manufacture the most special, professional , stable high pressure pure water jetting unit for our customers-also called hydro blaster or water blaster. Our UPH water cleaning system employ the demanding task in nearly all the industries. The system endows the safety, environmental-friendly, high efficiency, cost down and value more, widely used in cleaning heat exchanger, autoclave, pipeline, reaction kettle etc.

Why UHP Pure Water Cleaning

Equipment of Petrochemical industries as heat exchanger, condenser, autoclave, accumulated plenty of debris in the bundle tube, facing the risk of efficiency of heat exchanging, fluid flow, and heated unevenly to cause the pipe crack or even explode.

Scheduled cleaning is extremely important for production. Universally knowing, pure water cleaning is the most economic, safe, on contamination environmental friendly, low cost method of cleaning petrochemical industrial production equipment.

Scheduled cleaning is extremely important for production. Universally knowing, pure water cleaning is the most economic, safe, on contamination environmental friendly, low cost method of cleaning petrochemical industrial production equipment.

Heat Exchanger Cleaning Bundle Blaster

The Bundle Blaster system offers a powerful and affordable automated solution for external cleaning of heat exchangers, evaporators, condensers, and other industrial tube bundles. This system is ideal for contractors and plants interested in low maintenance, cost-effective, easy-to-use equipment. The Bundle Blaster is safer and more effective than traditional hand-held methods of shell side cleaning, and 1/3 of the cost of trailer mounted systems.

Boat & Ship Surface Rust and Paint Removal Solution

The robot enable shipyards, off shore, petrochemical and wide range of other industries to clean steel surfaces. allowing other trades to simultaneously perform other maintenance procedures. The robot offers a significant advantage over the traditional methods to remove marine growth, industrial coatings and corrosion. The robot is designed for all horizontal, overhead and vertical steel cleaning, blasting or custom engineered applications. It is remotely controlled for operator safety, comfort and productivity. The light weight construction and quick (dis)connect systems reduce the buildup time to approximately 10 minutes. The robot adheres to the wall by a magnetic drive assembly and can be moved independently. There is no need for crane assistance or cherry pickers.

Reactor Tank Cleaning Solution

Reactor tanks are critical components in various industries, including chemical manufacturing, pharmaceuticals, petrochemicals, and food processing. As these industries grow, so does the demand for efficient and reliable cleaning solutions for reactor tanks.

The market for reactor tank cleaning solutions is expanding due to the increasing need for regular maintenance, safety compliance, and operational efficiency.

The market for reactor tank cleaning solutions is expanding due to the increasing need for regular maintenance, safety compliance, and operational efficiency.

Hydro Demolition for Bridge Concrete Deck

Looking for safe and precise hydro demolition for your bridge deck? Our advanced water jet technology ensures efficient concrete removal with minimal structural impact. Contact us for customized solutions.

Airport Runway Rubber Removal Solution

Discover our eco-friendly Airport Runway Rubber Removal Equipment, using ultra-high-pressure water jet technology for safe and fast rubber deposit removal. Customizable for OEM and ODM needs, our system ensures optimal runway performance with minimal downtime. Get competitive factory prices for tailored solutions!

Advantages

What can Fedjetting UHP water cleaning offer you?

Advance water jetting technology improves efficiency, decrease operation cost, more safer, no contamination for your projects:

1.Save time on cleaning due to the excellent stable, easy operation, and automatic actuator, equivalent man operated three dump guns to cleaning the exchanger tube once, improve the efficiency.

1.Save time on cleaning due to the excellent stable, easy operation, and automatic actuator, equivalent man operated three dump guns to cleaning the exchanger tube once, improve the efficiency.

2. Only two person operate the machine, one of them operate the UHP water cleaning machine, the other operate the automatic actuator.

3.Pure water, no pollutant to contaminate environment compared with the traditional physical and chemical cleaning.

4.More important, it is easy operation, common worker can handle it.

Control System

1. Imported controller,

2. Real time monitoring diesel engine operate state.

3. Perfect for Harsh work conditions of high vibration, dust etc.

4. IP65 Grade

Diesel Engine

1. QSL-C360 Cummins engine

2. Max rotation: 2100RPM

3. Leading in-cylinder direct injection tech & cummins exclusive HPCR high effciency fuel system.

4. Special option: Pneumatic.

Power End

1. Export for the US market2. Crankshaft made by 42CrMo, 4:1 forging

3. Ratio:4.57, 460rpm on the full load

4. Forced lubracation

5. Oil temp and pressure alarm

3. Ratio:4.57, 460rpm on the full load

4. Forced lubracation

5. Oil temp and pressure alarm

Water Tank

1. Patented no-pressure filter system,

2. Double 10um fiter bags for long lifespan.

3. Imported mechanical floating valve can eliminate the water hammer.

4. Low water level shutdown system

5. Customized poly water tank with stronger corrosion resistance

Frame

1. Dual independent frame system, diesel and pump mounted on the separate plate

2. Machining datum of large milling machine to ensure the accurate of the assembly

3. Galveanized frame to meet the long term anticorrosion requirements

4. There's a toolbox in the frame

5. 350L aluminum fuel tank(with fuel level sensor)

Conversion

1. Conversion between 1400KG and 2800KG in 30min.2. Low water level shutdown system

3. Water temp shutdown system

4. Water presssure switch to keep the pressure of the water into the pump is eligible

5. Differential pressure alarm

6. Oil pressure alarm

7. Oil temp alarm

3. Water temp shutdown system

4. Water presssure switch to keep the pressure of the water into the pump is eligible

5. Differential pressure alarm

6. Oil pressure alarm

7. Oil temp alarm

Fedjetting Service

Fedjetting has been developing and innovating various new complete high pressure water jet cleaning solutions for more than 10years, we have rich experience in difference industries applications.

1. Maintenance free of charge for 12 months(1 year warranty for the machine)

2. We supply you the spare parts to you at an agency price.

3. 24*7 days a week, 365 day a year online service, free video support, and technical support.

4. All the parts and the whole water blaster have been tested and adjusted before delivery, trial Operation also is included. And provide with pressure and flow rate testing report by our QC department. If there is any problem, pls just contact us at any time.

5. Delivery with operation manual instruction and video on operation, daily maintenance, scheduled maintenance, problem shooting, safety principals, each parts introduction etc. Also we can send out our professional technician to customer's working site or factory , provide two-weeks training, including operation principle,maintenance ,problem shooting etc.

6. Can provide CO ( Form E/A /P) as your requirement.

Company Profile

ABOUT FEDJETTING

Fedjetting UHP Water Cleaning Solution: A complete solution to your projects in real application. Petrochemical industrial equipment cleaning, as heat excharger, reaction kettle, pipeline etc, all of these equipment from fedjetting with perfect solution, take heat exchanger for example, you need a UHP water clean unit, the hose, the automatic actuator, the dump gun, and foot valve.

Cost-Saving: Only need2 person for whole solutions, 1 control the water blaster, the other operate the actuator to move.

More Save: No need person holding a hand gun to flushing the heat exchanger face to face, avoiding the high pressure water hurt human body(also provide protection products.)

Double or even triple efficiency for your project, becuase each time we can clean the two or threee pipes in the bundles。

Outstanding Stable Equipment Performace: It's lessen the down time and maintenance, which can be worked continuously without stop over and night.

Customer Partner

FEDJETTING is trusted by ABB, FANUC, TST, SIEMENS, SCHNEIDER, PMI, HIWIN, YASHAWA, ECS, Jetstream, STONEAGE, KMT WATERJET, REXROTH

BOSCH GROUP, HYPERTHERM, SMC, PARKER. 100% worry-free partner.

BOSCH GROUP, HYPERTHERM, SMC, PARKER. 100% worry-free partner.

Certification and Cooperation Agency Certificate

We're confident with our products, so the passed cert is perfect for customer's satisfation, Also gain the agency ceftificate from Jetstream, Stoneage,

Shipment & Payment

Package:

1. Machine packed with wooden case is after fumigation treatment, there's no need timber inspection ,saving shipping and custom clearance time.

2. All spare parts packed with bubble foil , and outside packed with carton. In order to avoid any damage might happen in the shipment process, we vacuumed with aluminum foil film, make sure the cover intact, water-proof and fire-proof.

3. The out-most is wooden case with frame fixed.

4. The bottom packed with pallet, forklift and hoist hole reserved for easy transportation. Before delivery, we do have test the machine for 3-4 and use standard packing to each machine, also accept logo OEM. We choose famous and good service transportation agent and ship vessels, to ensure the machine transported more safer, faster to you.

2. All spare parts packed with bubble foil , and outside packed with carton. In order to avoid any damage might happen in the shipment process, we vacuumed with aluminum foil film, make sure the cover intact, water-proof and fire-proof.

3. The out-most is wooden case with frame fixed.

4. The bottom packed with pallet, forklift and hoist hole reserved for easy transportation. Before delivery, we do have test the machine for 3-4 and use standard packing to each machine, also accept logo OEM. We choose famous and good service transportation agent and ship vessels, to ensure the machine transported more safer, faster to you.

After-Sale

We provide you with comprehensive After-Sales Services, including:

1. 1-year Warranty: During the warranty period, we provide repair and replacement services to ensure that your equipment is always in optimal working condition.

2. Technical Support: Our professional technical team is ready to answer your questions about the use of the equipment and provide remote or on-site guidance to ensure that you can operate the equipment efficiently and safely.

3. Main Spare Parts Supply: We have sufficient original spare parts inventory, which can quickly meet your replacement needs and reduce equipment downtime.

4. Regular Maintenance: Based on your needs, we can provide remote regular maintenance services to prevent potential problems and extend the service life of the equipment.

5. Training Services: We provide detailed equipment operation and maintenance training so that your employees can master equipment usage skills and ensure production efficiency.

By choosing Fedjetting, you not only purchase an ultra-high-pressure water cleaning machine, but also enjoy our professional, timely and thoughtful after-sales service support to protect your production!

If you have any questions or need further assistance, please feel free to contact us.

2. Technical Support: Our professional technical team is ready to answer your questions about the use of the equipment and provide remote or on-site guidance to ensure that you can operate the equipment efficiently and safely.

3. Main Spare Parts Supply: We have sufficient original spare parts inventory, which can quickly meet your replacement needs and reduce equipment downtime.

4. Regular Maintenance: Based on your needs, we can provide remote regular maintenance services to prevent potential problems and extend the service life of the equipment.

5. Training Services: We provide detailed equipment operation and maintenance training so that your employees can master equipment usage skills and ensure production efficiency.

By choosing Fedjetting, you not only purchase an ultra-high-pressure water cleaning machine, but also enjoy our professional, timely and thoughtful after-sales service support to protect your production!

If you have any questions or need further assistance, please feel free to contact us.

FAQ

Q1. What is the pressure and flow rate of the UHP water blaster usually the petrochemical industrial used? |

A1:Usually, 1400bar, 95L/M and 2800bar and 45L/M the most used in the petrochemical industrial equipment cleaning. |

Q2. Does your petrochemical industrial equipment cleaning solution hard to operate? |

A2:No, it is very easy and simple to operate, and we support online technical, video, manual service. |

Q3. How do you help to solve the problem if we met when operation on working site? |

A3: First, response quickly to deal with the problem you met. And then if it is possible we can be your working site to help. |

Q4. What is your delivery time and payment term? |

A4:Will be 30days if have in stock, and will be 4-8weeks if don't have stock. The payment can be T/T. 30%-50%deposit in advance, the rest balance before delivery. |

Q5. Do you develop any foreign local agent? |

A5:Yes, we do develop local agent, detailed policy, please contact us. |

Q6. Do you provide the brand JET, NLB pump or ST, TST ACCESSORIES? |

A6:Yes, we can provide the authority brand JET, NLB,ST and TST PUMP AND ACCESSORIES. |

We Recommend

Surface Cleaner Water Blaster Roof Cleaning Machine

$4,100.00-4,500.00

15HP Pressure Washing Pump Suppliers 52lpm 100bar JPD5210

$830.00-850.00

New Arrivals

New products from manufacturers at wholesale prices