Custom Plastic Injection Moulding Service ABS Moulds Inject Supplier Molding

- Category: >>>

- Supplier: Dongguan Yeeshine Technology Co. LimitedDongguan Limited

Share on (1601274400803):

Product Overview

Description

Products Description

Professional High Precision Plastic Injection Mould Factory

Mould material | P20, 718, NAK80, S316H | ||||||

Hardness of steel | Vacuum quenching, nitride, hrc41-47, hrc46-50, hrc60 | ||||||

Mould base | LKM, HASCO | ||||||

Mould cavity | Single / Multi | ||||||

Runner system | Hot / Cold | ||||||

Injection machies equipments | According to product precision to choice the different model 100T,128T,150T,200T,250T,368T,450T injection machine. | ||||||

Inspection | 100% inspection by QC, QA before shipping. | ||||||

Fast mould design | Can be within 1-3 working days after getting customer's drawings | ||||||

Lead time | Plastic moulds : 3- 6 weeks after getting the mould design confirmation | ||||||

Mould testing | All of the moulds can be well tested before the shipments. Videos for moulds trial running are available. | ||||||

Minimum order | Small orders for injection moulding can be accepted | ||||||

Production capacity | 20 sets/month | ||||||

CAD for quote | Step.& dwg. | ||||||

Mould life | 100-500K shots | ||||||

After sales service | Available by our staff with more than 10 years of working experience in this field | ||||||

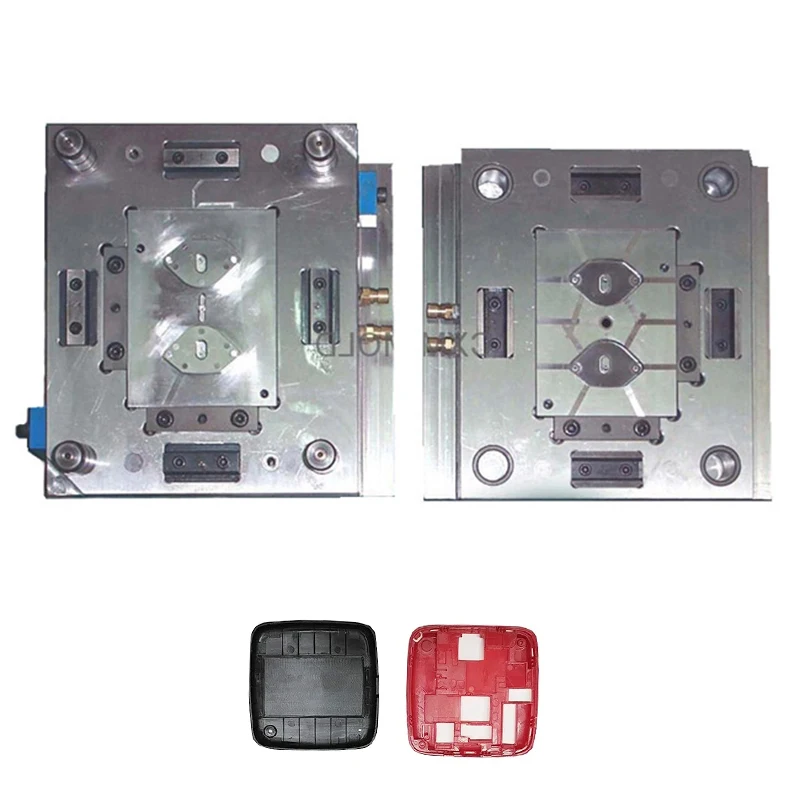

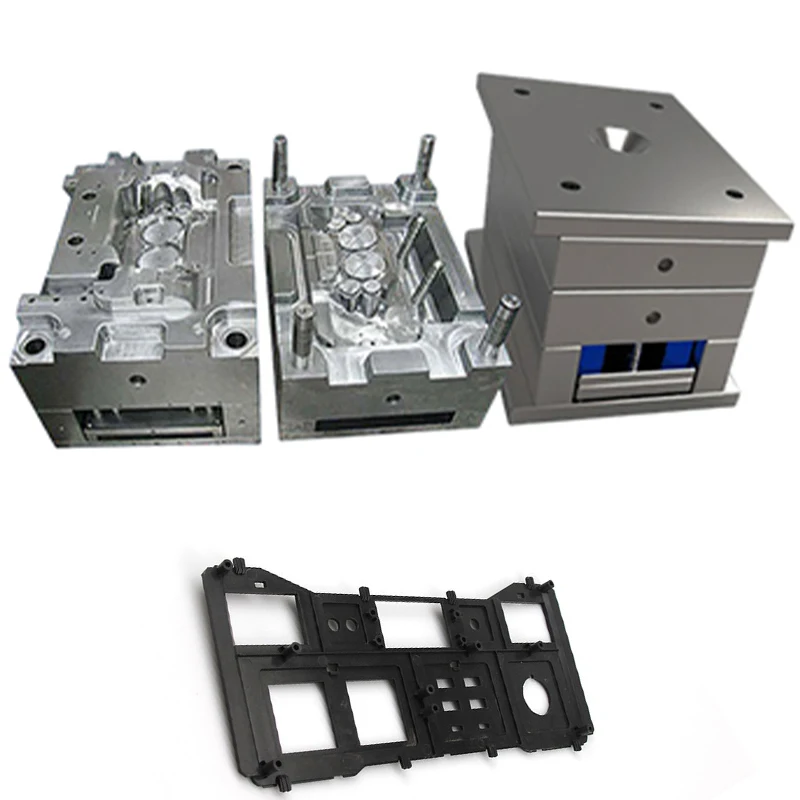

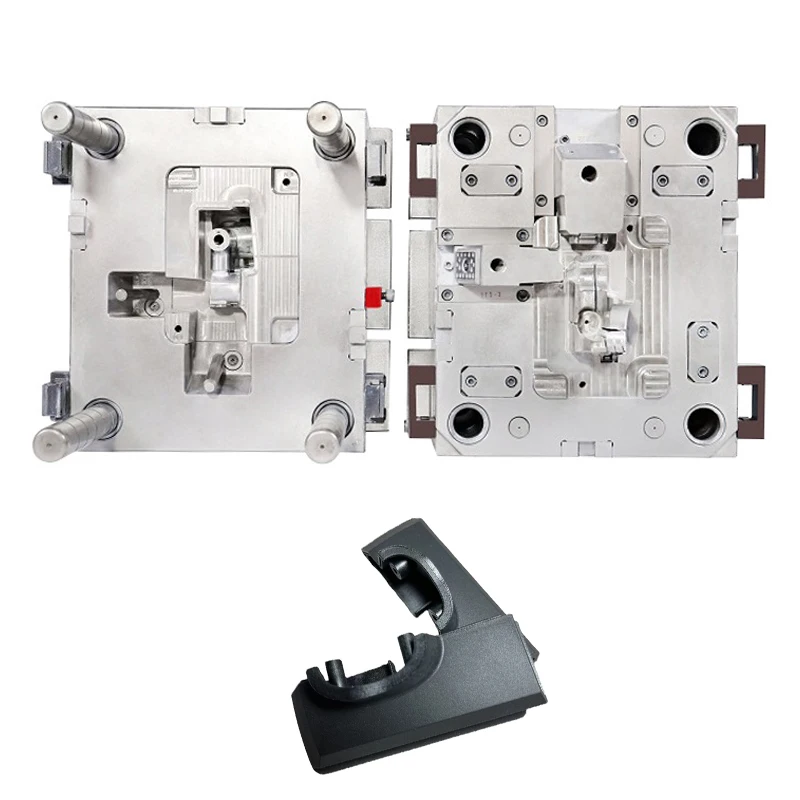

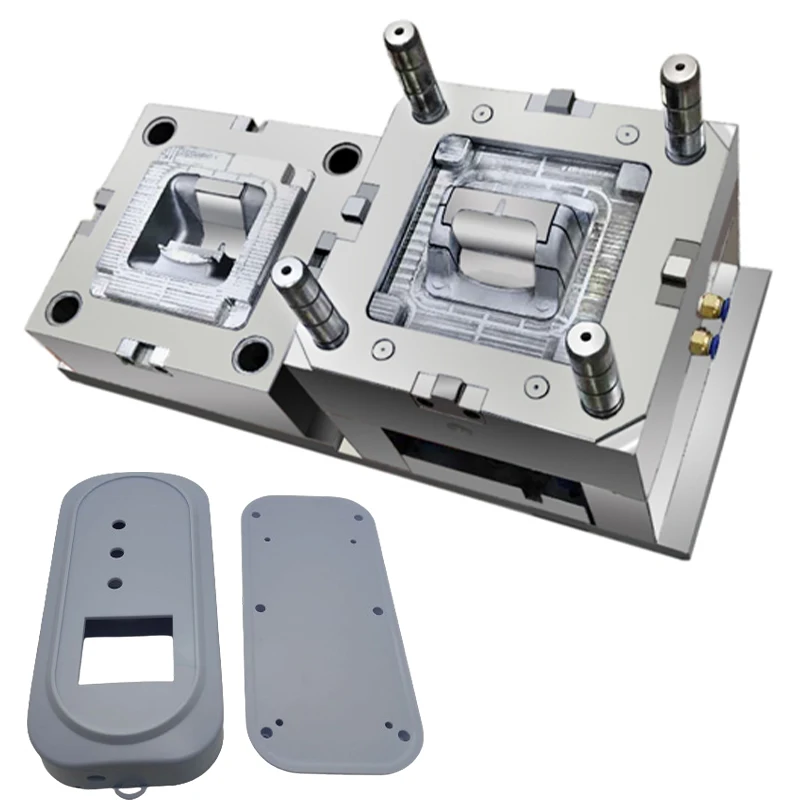

Product Show

CNC Plastic Preclslon Mechanlcal Dummy Prototype | 1. CNC ABS part | ||||||

2. CNC PC clear part | |||||||

3. CNC PMMA transparent | |||||||

4. CNC plastic part | |||||||

5. CNC machining prototype | |||||||

6. Vacuum casting molding | |||||||

7. Vacuum casting TPU part | |||||||

8. Silicon rubber molding partpart | |||||||

9. Small production by SLA/vacuum casting | |||||||

Plastic material | ABS, PP, PC, POM, PMMA, NYLON, TPE, TPU etc | ||||||

Color | RAL/PANTONE color | ||||||

Prototype surface finish | Polishing finish,Texture Finish,Glossy Finish,Painting,Slik print,Rubber Painting etc | ||||||

Manufacturing Ability

SLA Print / CNC machining Prototype

Share prototype quote within 24 hours.

Provide color painting and surface finish on both 3D print part and CNC machining parts.

ABS, PC clear, soft rubber, TPU, etc.

Provide color painting and surface finish on both 3D print part and CNC machining parts.

ABS, PC clear, soft rubber, TPU, etc.

Plastic Injection Mould

We provide one-stop service from part design analysis, CNC prototype making, mold design, cavity inserts machining to injection moulding mass production.

Free design analysis report.

Soft tooling, switch runner design.

Free design analysis report.

Soft tooling, switch runner design.

Injection Moulding Production

Single color injection and double-color injection molding service.

100-500T machines, small order accepted.

100-500T machines, small order accepted.

ABS, PC clear, TPU, Nylon, PC+TPU etc.

Injection Moulding Machine List | ||||||||||

Item | Machine Name | Model | Origin | QTY (Sets) | Mold Thickness (Max) | |||||

1 | Injection Machine | 450T | Japan | 1 | 800MM | |||||

2 | Injection Machine | 368T | HK | 2 | 700MM | |||||

3 | Injection Machine | 250T | HK | 2 | 600MM | |||||

4 | Injection Machine | 200T | HK | 3 | 500MM | |||||

5 | Injection Machine | 150T | HK | 3 | 400MM | |||||

6 | Injection Machine | 128T | HK | 3 | 400MM | |||||

7 | Injection Machine | 100T | HK | 1 | 350MM | |||||

Our Service

Scanning & 3D drawing | can make a 3D drawing through scanning machine with sample | ||||||

CNC Machining prototype | ABS, PC, Nylon, good strength, same material features as injection parts | ||||||

SLA & 3D print prototype | cost effective for part show or design test | ||||||

Vacuum casting mold /Silicon mold | for TPU or rubber material, color part available | ||||||

Plastic injection mould | soft tooling or production mould, can do switch runner at single tool to save tooling investment | ||||||

Injection moulding parts | ABS, PC, POM, TPU, overmolding parts, can provide painting or logo print service | ||||||

Advantages | Confidentiality | Signed NDA documents to ensure all your information discussed be confidential. We will also train the staff with detailed regulations and not showing the staff full data if not necessary. | |||||

Initiative communication | Through many years cooperation with our partners, we are confident to provide you satisfied quality with a reasonable price. Not only providing satisfied quality and on-time delivery, but we also have a dedicated and initiative staff for every issue happened in the process. | ||||||

Efficient service | For some urgent issues, we provide 7*24 hours for timely feedback.We will reply your mail within 12 hours or earlier since our team members are energetic and all using smartphone devices.Please add our whatsapp or wechat for better communication | ||||||

Advantage in price | We are also happy to follow up your other projects which need outsourcing service, what we think is to save your plant visit cost and transportation cost etc. Our team's goal is to work hard to find out the best price with good quality products for our customers and achieve more trust and confidence on both sides | ||||||

Product packaging

How To Order

Delivery Method:

Sample by Express Courier, such as DHL, Fedex,UPS, TNT, EMS etc.;

Bulk Order by Air, by Load or by Sea;

Bulk Order by Air, by Load or by Sea;

Payment Terms:

We accept TT, western union, paypal, moneygram, Escrow , (if you prefer other ways ,pls let us know)

Warranty Period:

We cherish every cooperation chance, and treat customer as friend. Production quality will always be same with sample test. For defected goods, we will re-produce and ship out for replacement.

Company Profile

Why Choose Us

FAQ

Q1:What is your business scope?

A1: Our factory provides CNC plastic prototype, Plastic injection mould, moulding production, logo print and color painting.

Q2:Can you help to share an idea for a new product?

A2: Yes. We are always happy to cooperate with potential customers to evaluate the technical feasibility. Like, choose the right material, optimized the design, DFM report, and building cost etc.

Q3:Can you make double color injection mold or over-molding mould?

A3: Yes, we can. Have made lots of double color molds for brand earphones.

Q4:Which country do you frequently work with?

A4: Our customer groups mainly from USA, Canada, Mexico, Australia, Japan, Singapore, India, Israel etc.

Q5:How to have my components quoted?

A5: Please share us your drawings with 3D format (.STEP or .IGES files) and detailed BOM sheet. We are pleased to sign the NDA with your company.

A1: Our factory provides CNC plastic prototype, Plastic injection mould, moulding production, logo print and color painting.

Q2:Can you help to share an idea for a new product?

A2: Yes. We are always happy to cooperate with potential customers to evaluate the technical feasibility. Like, choose the right material, optimized the design, DFM report, and building cost etc.

Q3:Can you make double color injection mold or over-molding mould?

A3: Yes, we can. Have made lots of double color molds for brand earphones.

Q4:Which country do you frequently work with?

A4: Our customer groups mainly from USA, Canada, Mexico, Australia, Japan, Singapore, India, Israel etc.

Q5:How to have my components quoted?

A5: Please share us your drawings with 3D format (.STEP or .IGES files) and detailed BOM sheet. We are pleased to sign the NDA with your company.

Q6:Can I have precision prototypes for testing before tooling design?

A6: Sure, our factory can prepare the prototype with surface finish and color painting, either CNC machining or SLA 3D printing is available.

Q7:What is the lead time for CNC prototypes?

A7: It is about 4 to 7 days for qty less than 5sets, and 7 to 12 days for qty above 10sets. Before painting process, we will polish and test part assembly, and then share video for confirmation.

A7: It is about 4 to 7 days for qty less than 5sets, and 7 to 12 days for qty above 10sets. Before painting process, we will polish and test part assembly, and then share video for confirmation.

Q8:We've decided to go ahead for the project. How long will it take to get T1 parts?

A8: It takes 3 to 4 weeks to have the mould/tooling manufactured well before first tooling trial. Once the part quality approved with good quality by your side, you can expect parts delivery within two weeks.

A8: It takes 3 to 4 weeks to have the mould/tooling manufactured well before first tooling trial. Once the part quality approved with good quality by your side, you can expect parts delivery within two weeks.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices