Powerful Electromagnetic Brake Delivering Strong Braking Force

- Category: >>>

- Supplier: Chengdu CDC Technology Co. Ltd.

Share on (1601274409681):

Product Overview

Description

According to customer needs, our CDC can develop and design various standard products. CDC offers over 2,000 specifications of brake products, with torque ranging from 0.006 Nm to over 1,000 Nm, outer diameters from 15 mm to 450 mm, and thicknesses from 9 mm to 300 mm, to meet the diverse demands across different market sectors! For personalized advice and further information, please contact us now. CDC will arrange a discussion to help you select the best brake solution for your application.

Products Description

Product series | Torque range | Voltage | Insulation class | Main Application |

CDC-S | 0.32-44 | 24 | F | Servo Motors |

CDC-CB | 0.06-3.2 | 24 | F | Robots, Mechanical Arms |

CDC-C | 6-16 | 24 | F | Electric Forklifts |

CDC-Z | 0.25-2 | 96 | F | General Motors |

CDC-ZT | 3-1350 | 96 | F | Various Equipment |

CDC-W | 0.25-2 | 96 | F | Micro Motors |

The CDC-S series electromagnetic brake is meticulously designed and developed by our company as a small and medium-sized electromagnetic spring-applied fail-safe brake, specifically for servo motors. This series of products features quick braking time, low operating noise, stable operation, good control performance, and high-cost performance. The products are widely used in industries ( submarines, outer space, etc.), ATMs, plotters, engravers, spraying equipment, medical instruments and equipment, computer peripherals and mass storage devices, precision instruments, industrial control systems, automation, robots, computerized embroidery machines, textile machines, and other work product control fields.

Main Features

* Used for holding braking

* Can withstand a certain number of emergency stops

* Small size achieves high torque

* Torque range: 0.32-44 N·m

* Long service life

* Uses imported high-wear-resistant friction plates, durable

* Used for holding braking

* Can withstand a certain number of emergency stops

* Small size achieves high torque

* Torque range: 0.32-44 N·m

* Long service life

* Uses imported high-wear-resistant friction plates, durable

CDC-SG Series Ultra-thin Servo Electromagnetic Brakes

The CDC-SG series electromagnetic brake is meticulously designed and developed by our company as a small and medium-sized electromagnetic spring-applied fail-safe brake, specifically for ultra-thin servo motors. By using a dedicated controller, it achieves high power start and low power maintenance. It has the advantages of being ultra-thin, energy-saving, low heat generation, high torque, and long service life. This product is extensively used in robots, mechanical arms, and other ultra-thin servo motors where space is tight and size requirements are high.

Main Features

* Used for holding braking

* Can withstand a certain number of emergency stops

* Small size, ultra-thin

* Torque range: 0.06-3.2 N·m

* Long service life

* Uses imported high-wear-resistant friction plates, durable

* Minimal backlash

* Spline structure, backlash 0.2°~0.5°

* Used for holding braking

* Can withstand a certain number of emergency stops

* Small size, ultra-thin

* Torque range: 0.06-3.2 N·m

* Long service life

* Uses imported high-wear-resistant friction plates, durable

* Minimal backlash

* Spline structure, backlash 0.2°~0.5°

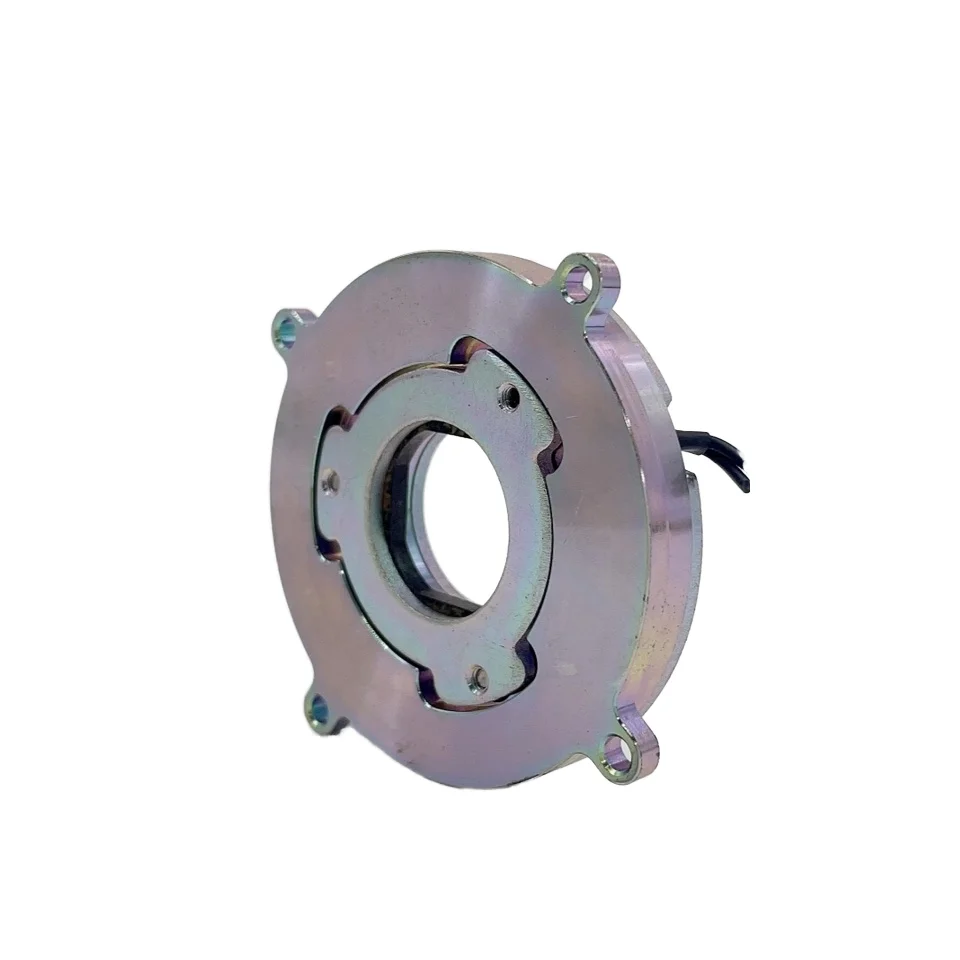

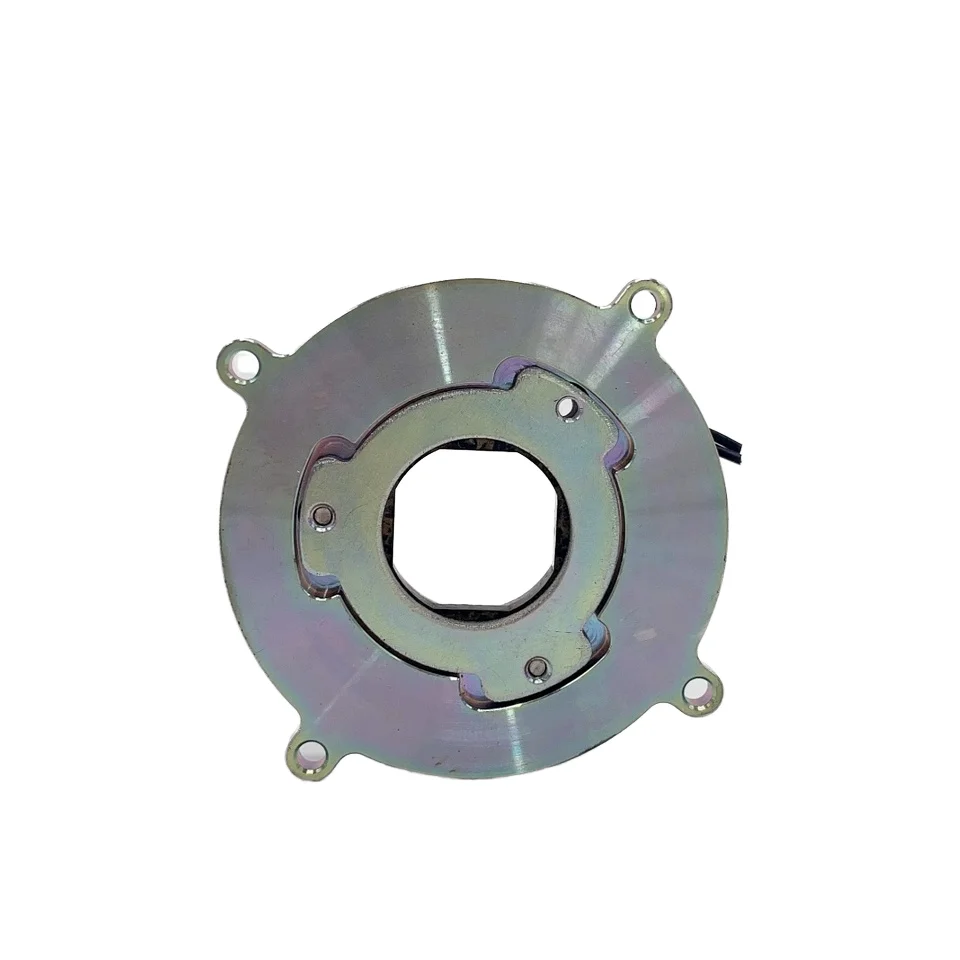

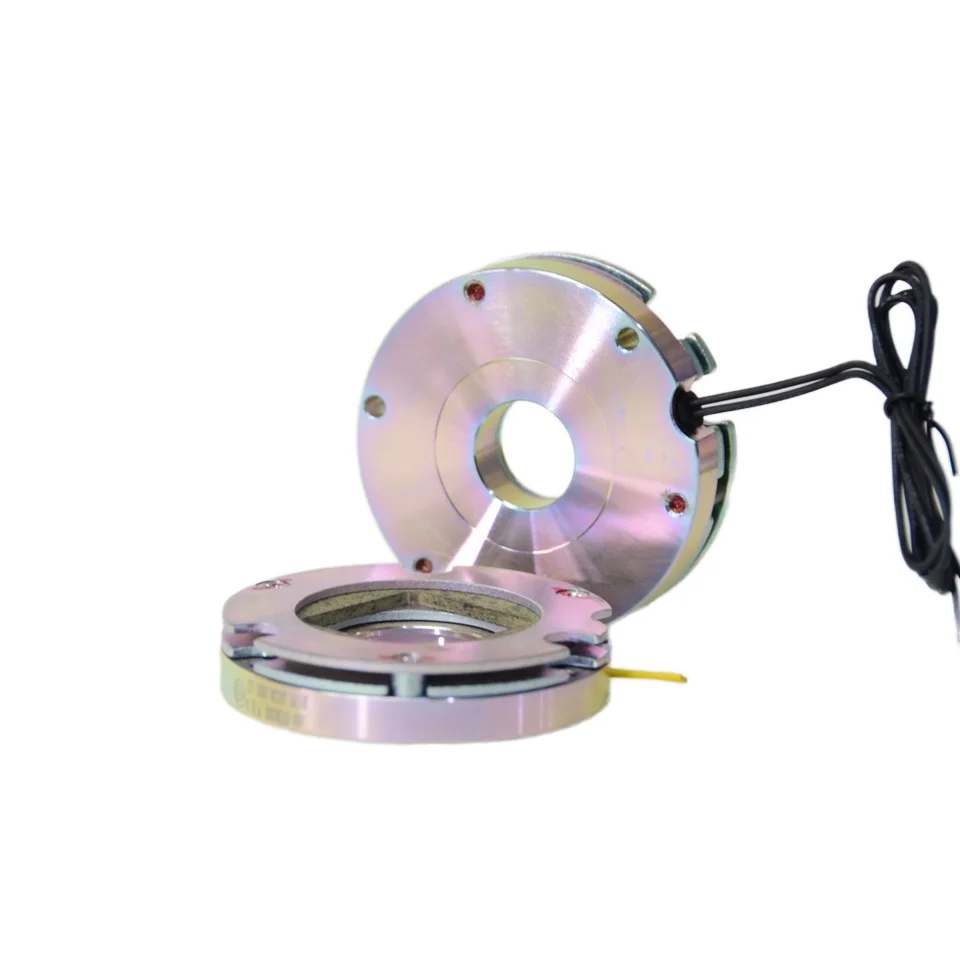

CDC-C Series Electromagnetic Brakes for Electric Forklifts

The CDC-C series brake is a spring-applied electromagnetic fail-safe brake, mainly used for braking the drive wheels of small and medium-sized electric forklifts. Installed in the drive wheel assembly, it brakes the drive shaft to achieve parking and emergency braking for the electric forklift, making it more effortless, safer, and more efficient for the user.

Main Features

* Used for deceleration braking

* Low noise, quiet braking

* Large angle design, more flexible operation

* Small size achieves high torque

* Torque range: 6-16 N·m

* Long service life

* Uses imported high-wear-resistant friction plates, durable

* Suitable for high-temperature environments

* Operating temperature: -10~+40°C

* Sealed design, improves protection level

* Used for deceleration braking

* Low noise, quiet braking

* Large angle design, more flexible operation

* Small size achieves high torque

* Torque range: 6-16 N·m

* Long service life

* Uses imported high-wear-resistant friction plates, durable

* Suitable for high-temperature environments

* Operating temperature: -10~+40°C

* Sealed design, improves protection level

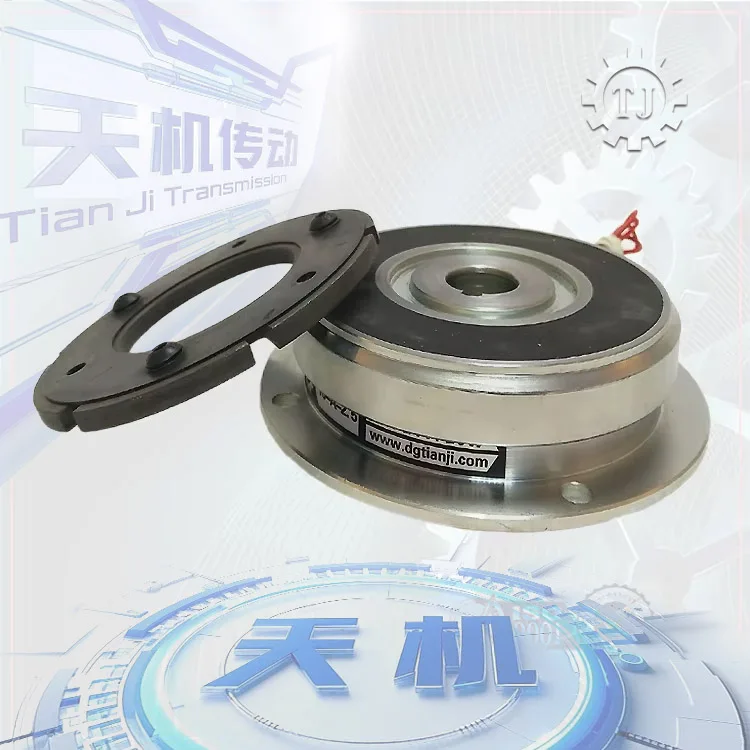

Z Series Electromagnetic Brakes for General Motors

Main Features

* Used for deceleration braking

* Low noise, quiet braking

* Long service life

* Uses high-wear-resistant friction plates, durable

* Suitable for high-temperature environments

* Operating temperature: -10~+40°C

* Optional manual release function and protective cover for easy maintenance

* Used for deceleration braking

* Low noise, quiet braking

* Long service life

* Uses high-wear-resistant friction plates, durable

* Suitable for high-temperature environments

* Operating temperature: -10~+40°C

* Optional manual release function and protective cover for easy maintenance

Company Profile

CDC Brake-Your Reliable Brake System Expert

CDC has been a leading high-precision brake manufacturer for 10+ years, with OEM and ODM production. We specialize in development and design of precision brakes, such as electromagnetic brake, servo brake, power-off brake, spring-applied electric brake, industry brake, Timing Pulley, keyless locking device and couplings.CDC has 16+ produce lines with 350 employees,35+ person R&D team and 30 QA&QC. 2023 annual output reached 1.5 million sets. Workshop covers an area of 20,000 square meters.

CDC Core Technology

1.We can make the brake with the torque from 0.006N.m to5000N.m.

2.The thinnest brake only 7mm, dynamic braking times 2000 times.

3.Ultra low temperature 196 degrees.

In China,currently there are no national or industry standards for servo brakes. CDC is leading the drafting of the "General

Technical Conditions for Electromagnetic Brakes for Servo Motors" standard.

Technical Conditions for Electromagnetic Brakes for Servo Motors" standard.

In 2022, CDC as approved as a council member of the China Motion Control Industry Alliance (the only member in the braking

sector)! CDC leads the domestic market in high-end brakes used in the robotics and servo industries. In 2023, our shipment volume

exceeded 1.5 million units, making us the preferred choice for replacing Japanese, German, and American brands. We have also started exporting electromagnetic brakes overseas. Most domestic robots and manipulators use brakes from the "CDC"

brand.

exceeded 1.5 million units, making us the preferred choice for replacing Japanese, German, and American brands. We have also started exporting electromagnetic brakes overseas. Most domestic robots and manipulators use brakes from the "CDC"

brand.

Produce&Test Equipment

Disc Brake Keyway Dual-Station Robotic Vertical Shaper

Disc Brake Keyway Dual-Station Robotic Vertical Shaper

Disc Brake Turning CNC Single-Station Robotic Lathe

Static Life Test Area

Fixed-speed Friction Test Machine

Backlash Test Area

There is more than 150+ testers in CDC. The following are CDC's normal tests to ensure the quality of our products.

1. * Static Braking Force Test: Measure the braking force of the brake under static conditions to ensure it meets design

specifications.

specifications.

2. * Dynamic Braking Force Test: Test the braking force of the brake under actual operating conditions, simulating the braking effect during operation.

3. * Response Time Test:Test the time it takes for the brake to start braking after receiving a control signal, ensuring that its response speed meets

design requirements.

design requirements.

4. *Braking Accuracy Testing: Evaluate the braking accuracy of the brake under different loads and operating conditions to ensure consistent and precise braking performance.

5. * Heat Resistance Test: Test the brake’s performance in high-temperature environments to ensure it does not fail under

high-temperature conditions.

high-temperature conditions.

6. * Friction Testing:Measure the coefficient of friction of the brake to evaluate the performance and wear resistance of the friction materials.

7.* Fatigue Testing: Assess performance changes in the brake during long-term repeated loading and unloading processes.

8. *Insulation Performance Testing Check the electrical insulation performance to ensure that the electromagnetic coil and other electrical components do not experience leakage or short circuits during normal operation.

9 * Overload Testing: Test the brake’s performance under conditions of overload to ensure it does not fail or pose safety risks in extreme conditions.

10. * Fault Mode Testing: Simulate different fault modes to evaluate the brake’s response and safety in case of failures.

Exhibition

Certifications

Product packaging

Why Choose Us

1. Extensive Industry Experience: Leveraging more than decades of expertise, we have honed our skills in producing reliable and innovative braking solutions. Our long-standing presence in the industry reflects our commitment to quality and excellence.

2. Advanced Technology: We invest in cutting-edge technology and state-of-the-art machinery to ensure our products meet the highest standards of performance and safety. Our R&D team continuously explores new technologies to stay ahead of industry trends.

3. Quality Assurance: Our products undergo rigorous testing and quality control processes to guarantee durability and

reliability. We adhere to international standards and certifications to ensure our braking systems exceed customer

expectations.

4. Customization Capabilities: Understanding that each client has unique needs, we offer tailored solutions and customized products. Our team works closely with clients to design and manufacture braking systems that perfectly match their specifications.

5. Customer-Centric Approach: We prioritize customer satisfaction and build long-term relationships by offering exceptional service and support. Our dedicated team is always available to provide technical assistance and address any concerns.

6. Sustainable Practices: Committed to environmental responsibility, we implement sustainable practices in our manufacturing processes. We focus on reducing our carbon footprint and using eco-friendly materials wherever possible.

Choose us for a reliable partner in braking systems, where experience, innovation, and customer satisfaction are at the heart of everything we do.

2. Advanced Technology: We invest in cutting-edge technology and state-of-the-art machinery to ensure our products meet the highest standards of performance and safety. Our R&D team continuously explores new technologies to stay ahead of industry trends.

3. Quality Assurance: Our products undergo rigorous testing and quality control processes to guarantee durability and

reliability. We adhere to international standards and certifications to ensure our braking systems exceed customer

expectations.

4. Customization Capabilities: Understanding that each client has unique needs, we offer tailored solutions and customized products. Our team works closely with clients to design and manufacture braking systems that perfectly match their specifications.

5. Customer-Centric Approach: We prioritize customer satisfaction and build long-term relationships by offering exceptional service and support. Our dedicated team is always available to provide technical assistance and address any concerns.

6. Sustainable Practices: Committed to environmental responsibility, we implement sustainable practices in our manufacturing processes. We focus on reducing our carbon footprint and using eco-friendly materials wherever possible.

Choose us for a reliable partner in braking systems, where experience, innovation, and customer satisfaction are at the heart of everything we do.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices