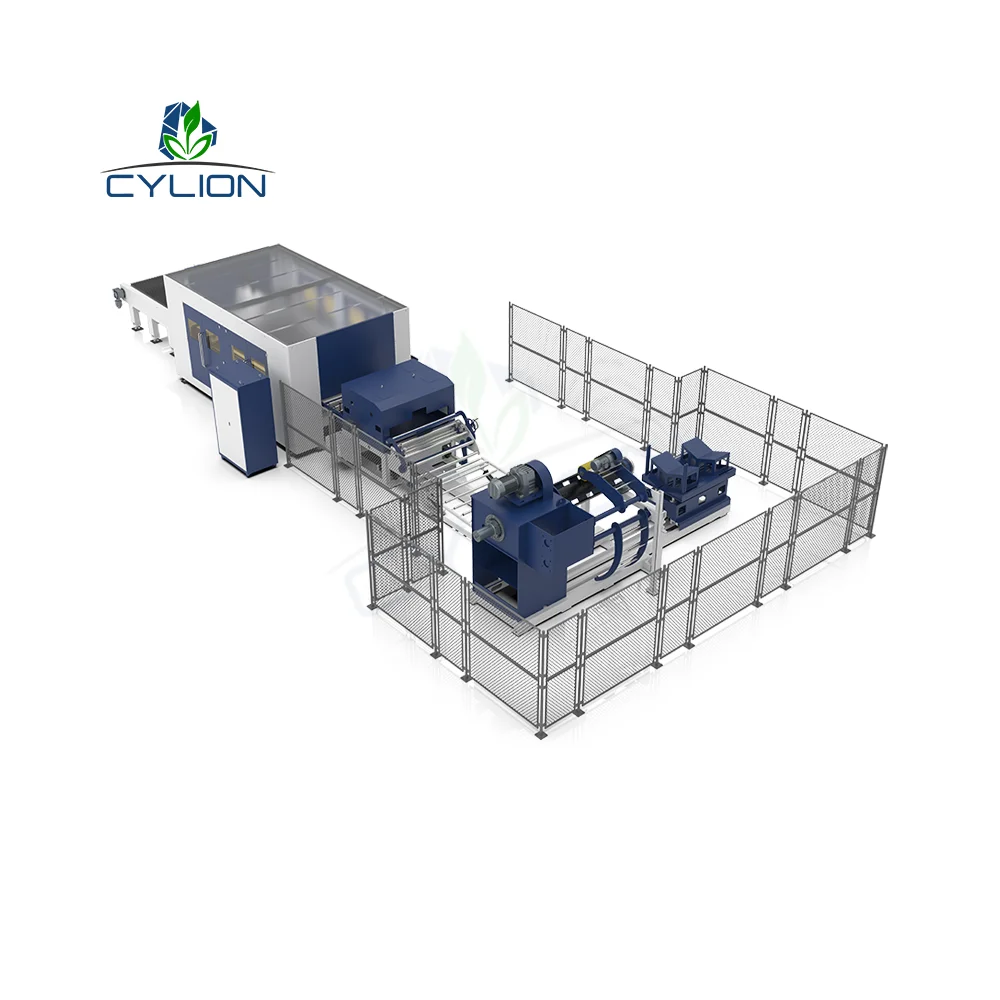

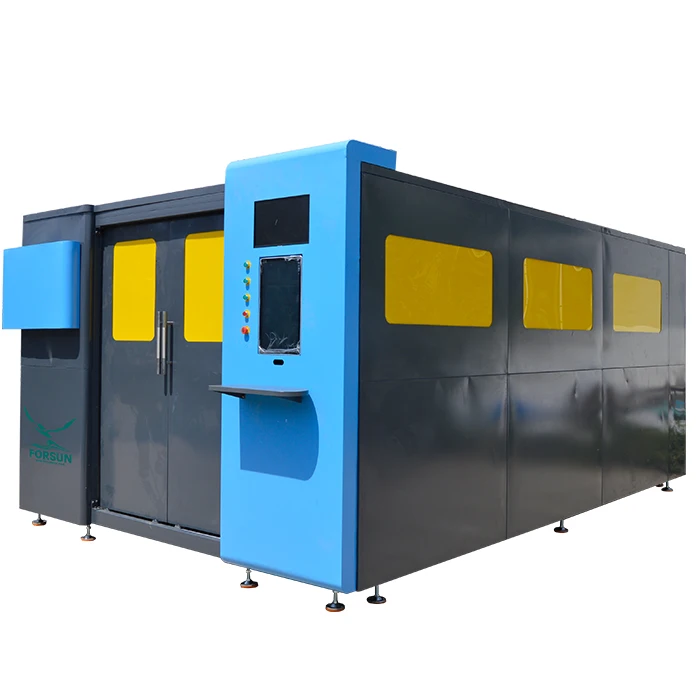

JUGAO 6kw Fiber Laser Cutting Machine High Precision Pipe And Plate Laser Cutting Machine

- Category: >>>

- Supplier: JUGAO CNC MACHINE JIANGSU CO LTD

Share on (1601274513205):

Product Overview

Description

6kw Fiber Laser Cutting Machine High Precision Pipe And Plate Laser Cutting Machine

Fiber laser cutting machine adopting world famous Germany fiber laser source and USA laser mech cutting head and dynamic focus system, it can cut and punch different kinds of metal material with high precision and high speed. Since laser is transmitted by fiber , it is no need to maintenance or adjusts the laser optical path , it greatly reduces the machines fault rate and prolongs the working life. Large format cutting area meets the demands of various kinds of metal processing .

Product Features

This series of products is the preferred model in the metal material processing industry, with powerful cutting capabilities, "flying" cutting speed, ultra-high stability, high-quality processing, extremely low operating costs and ultra-high adaptability.

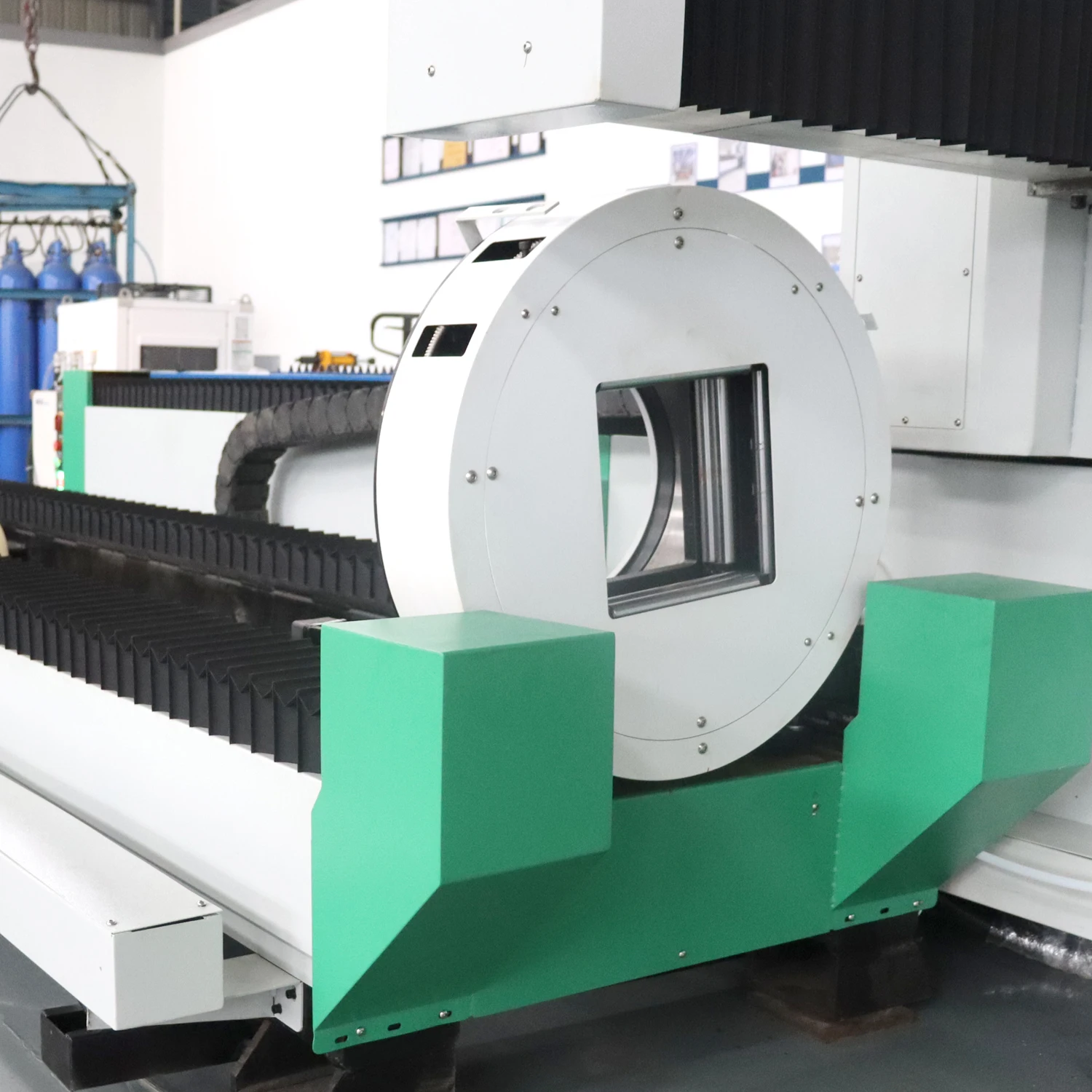

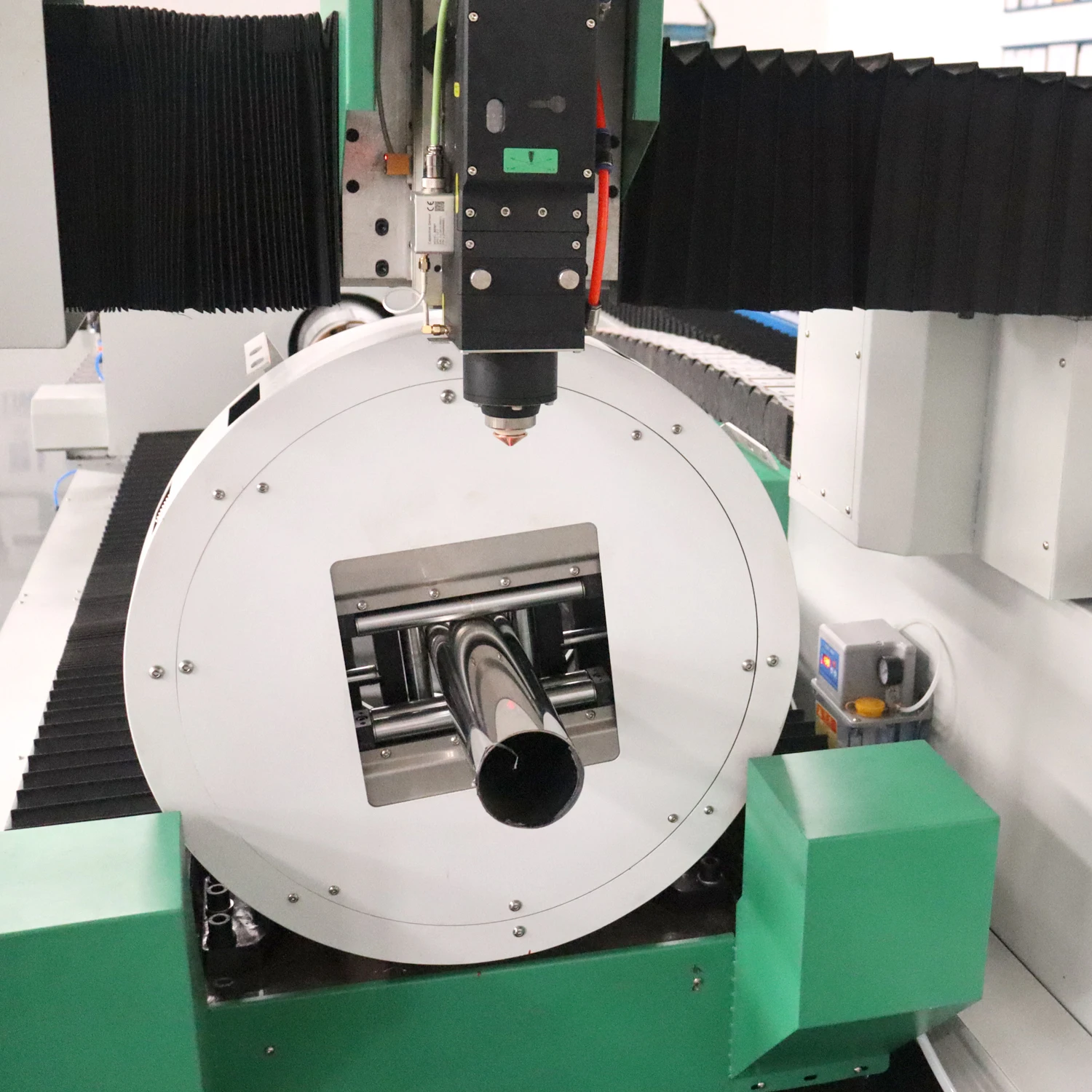

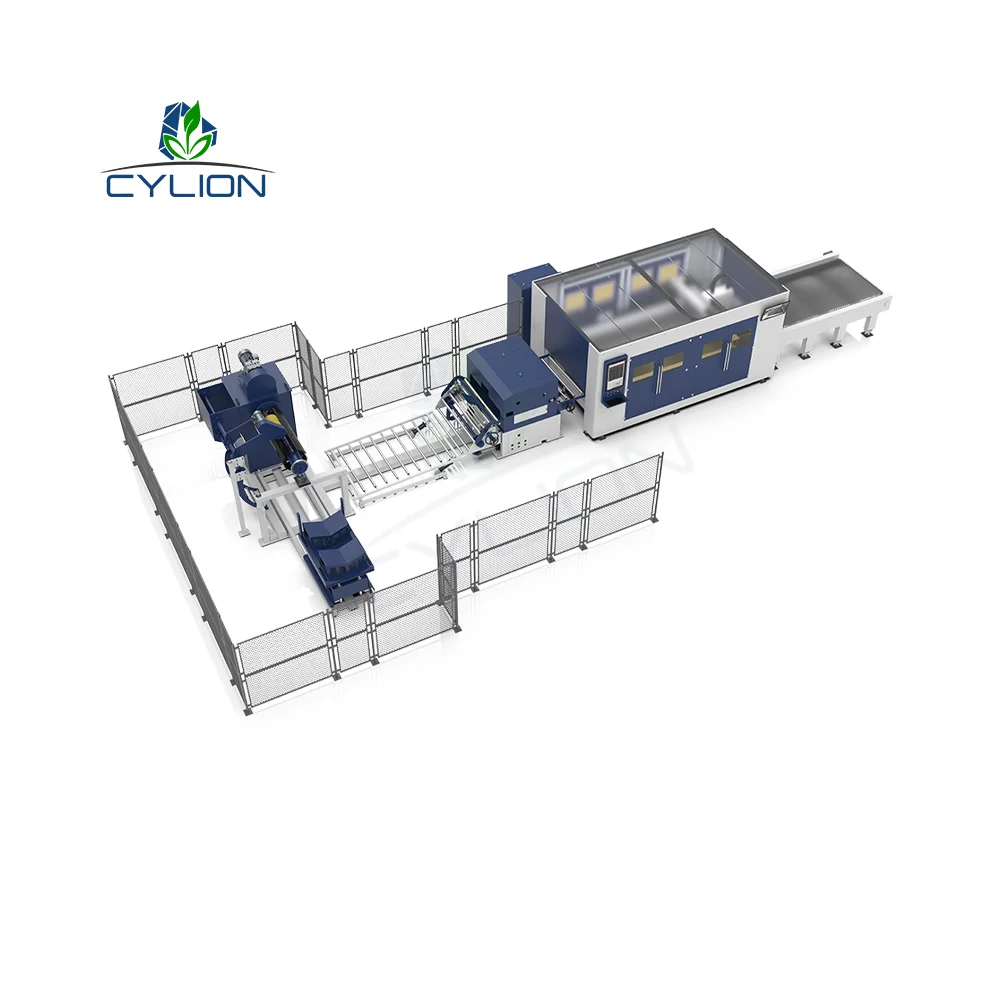

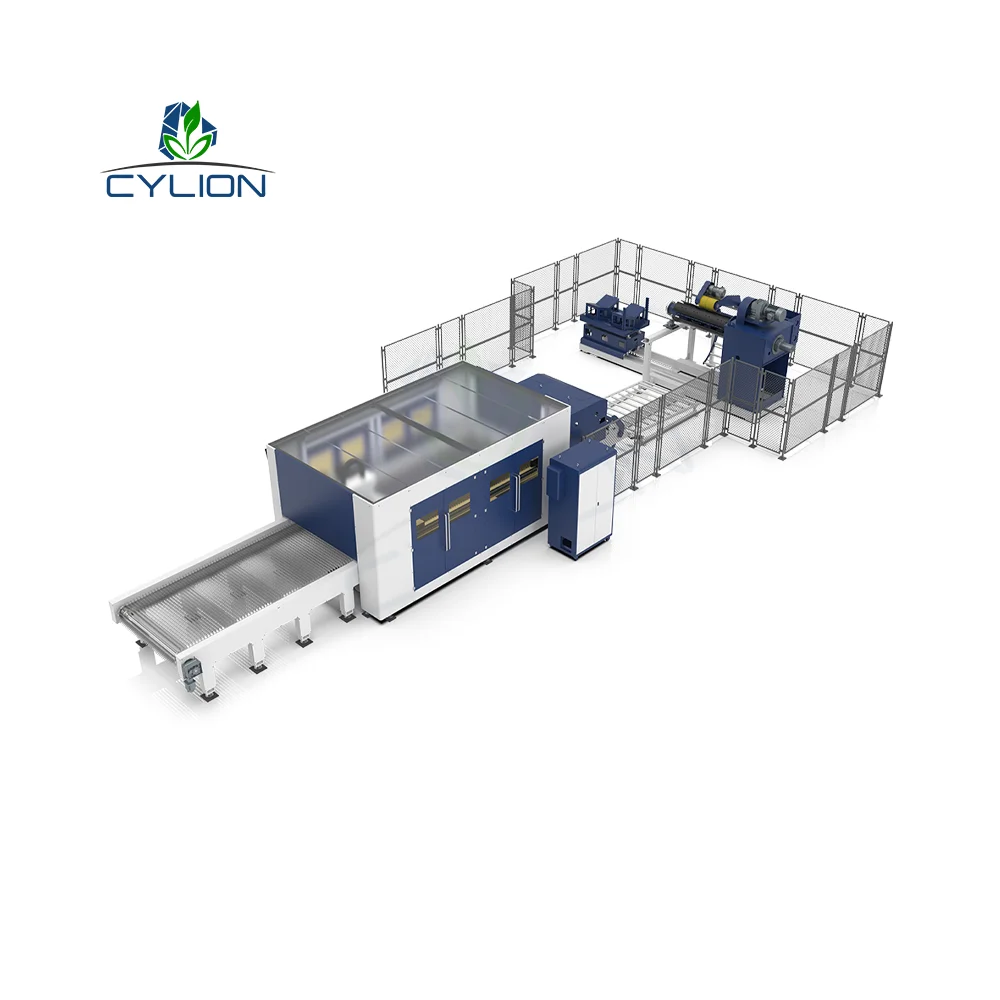

It integrates flat plate cutting and pipe cutting. It can be used to cut ordinary metal plates and various common pipes such as round pipes, square pipes, angle irons, etc. It is a multi-functional integrated equipment.

It adopts a gantry dual-drive structure, which has the characteristics of stable structure, good rigidity and high speed. Its X and Y single-axis positioning speed can reach more than 80m/min. At the same time, the dual-drive acceleration makes the maximum acceleration of X and Y single axes reach 1G.

The bed is an integral welded structure, which has been subjected to multiple aging treatments and has the advantage of good dynamic response. In terms of transmission, it is equipped with high-precision linear guides, high-precision reducers and gear integrated parts, grinding racks and other high-precision and efficient transmission mechanisms, with good rigidity and high precision to ensure long-term high-precision operation of the equipment.

It adopts independently developed fiber laser, has extremely strong cutting ability and efficiency, and is a high-end and high-tech fiber laser cutting machine that integrates advanced technologies such as laser cutting, precision machinery, and CNC technology.

Product Application

Automobile manufacturing, machinery and equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising logo, car decoration, sheet metal production, lighting hardware, display equipment, precision parts, hardware products, subway accessories, decoration, textile machinery, food machinery , Construction machinery, ships, tooling, metallurgical equipment, aviation, aerospace and other manufacturing and processing industries;

Laser Cutting machine is suitable for variety of metal plates, pipes ( with special device ), stainless steel, carbon steel, galvanized sheet, pickling board, brass plate, aluminum plate, manganese steel, all kinds of alloy plates, rare metals etc.

Technical parameter

| Mode No | JY-3015A/P30 | JY-4020A/P60 | JY-3015C/P30 | JY-4020C/P60 |

| Laser Power | 500W-2000W | 500W-2000W | 700W-3000W | 700W-3000W |

| Working Pange | 3000mmx1500mm 20-150mmx3000mm 20*20 100*100mmx3000mm | 4000mmx2000mm 20-150mmx6000mm 20*20 100*100mmx6000mm | 3000mmx1500mm 20-150mmx3000mm | 4000mmx2000mm 20-150mmx6000mm 20*20 100*100mmx6000mm |

| 20*20 100*100mmx3000mm | ||||

| Y1 Axis track | 3050mm | 4050mm | 3050mm | 4050mm |

| Y2 Axis track | 3200mm | 6200mm | 3200mm | 6200mm |

| XAxis track | 2825mm | 3325mm | 2825mm | 3325mm |

| W Axis track | Infinite rotation | Infinite rotation | Infinite rotation | Infinite rotation |

| Z Axis track | 270mm | 270mm | 270mm | 270mm |

| Y Axis accuracy | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

| Y Axis max. acceleration | 0.8G | 0.8G | 1.2G | 1.2G |

| Y Axis max.Speed | 80m/min | 80m/min | 100m/min | 100m/min |

| Max.load of worktable | 0.8T | 1T | 0.8T | 1T |

| Max.load ofpipe worktable | 0.1T | 0.2T | 0.1T | 0.2T |

| Net Weight | 5.3T | 7.5T | 7T | 10T |

| Dimension(LxWxH) | 5000mmx3700mm x1600mm | 9000mmx4200mm x1600mm | 8300mmx3700mm x1600mm | 10300mmx4200mm x1600mm |

OPITING PART

Laser Generator ——Raycus IPG

CYPCUT 2000

Cutting Torch : BM110 WSX Precitec

Automatic table exchanger

Pipe cutting Device

AIR COMPRESSOR

Cover Segmented Smoke Exhaust System

Machine Table Slat Cleaner Anti-collision system

|

|

Guarantee period:

Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers’ incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.

|  |

We Recommend

New Arrivals

New products from manufacturers at wholesale prices