KLS french fries potato chips banana chips 3 in 1 food production line

- Category: >>>

- Supplier: Weifang Kelesi Machinery Technology Co. Ltd.

Share on (1601274715497):

Product Overview

Description

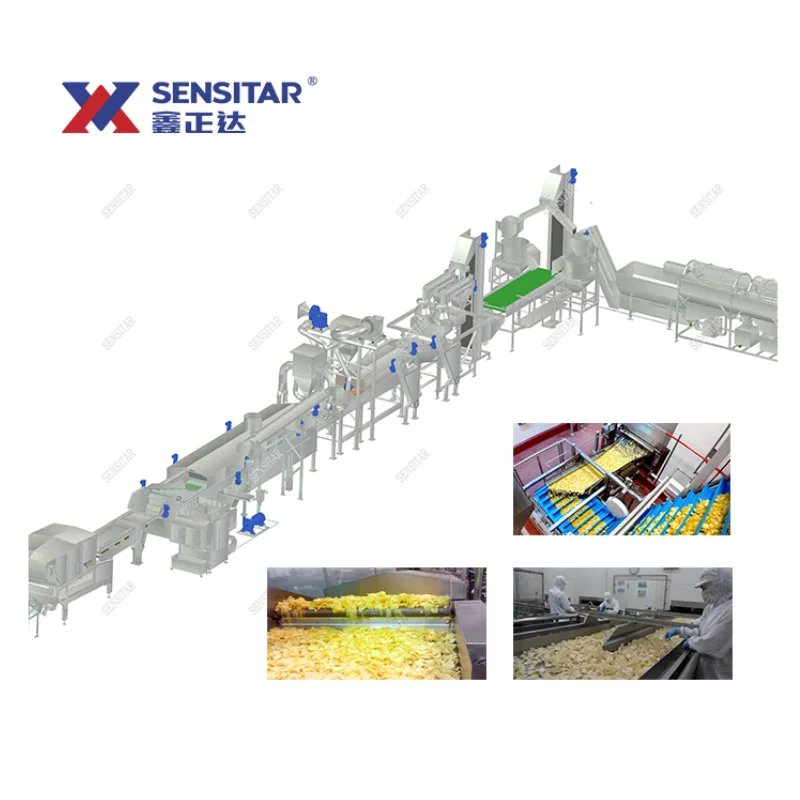

3-in-1 Production Line: Potato Chips, French Fries, Banana Chips

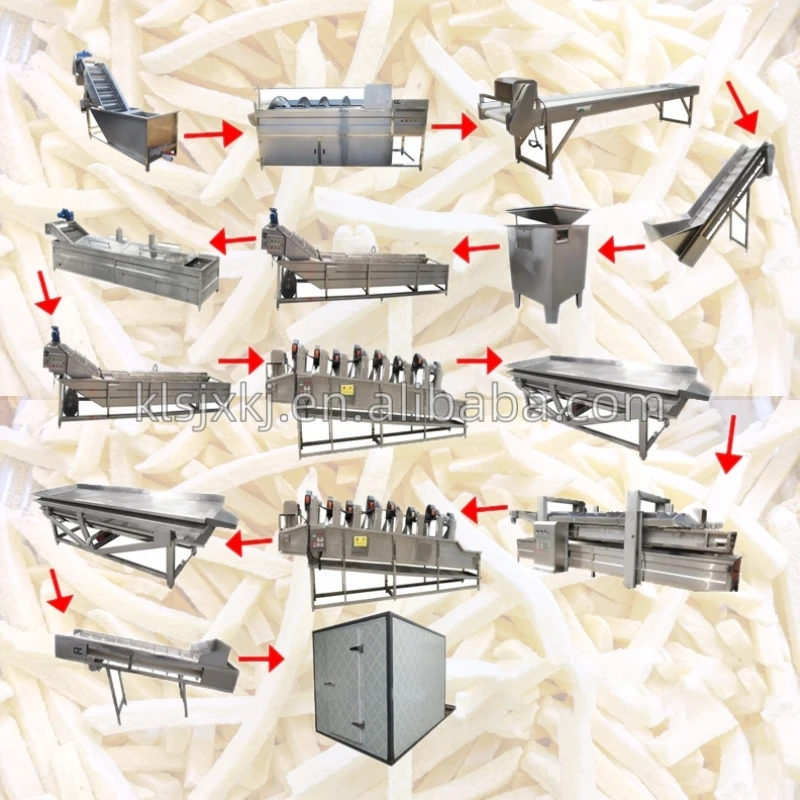

The whole production line is done by cleaning peeling, slicing (article), washing, blanching, rinse, dehydration, frying, deoiling, flavor, packaging, etc. We can provide free formulation and technical guidance, to make sure that you fry out high-quality chips of chips. If need a frozen line, plus a quick-freezing machine. The entire assembly line consists of cleaning, peeling, slicing (striping), washing, blanching, rinsing, dehydration, frying, deoiling, seasoning, packaging, and other processes.

Main Component Machine | ||||||||

Number | Name | Type | Specification | Material | ||||

1 | Hoister | CSJ3500 | Set | SUS | ||||

2 | Spiral Washing and Peeling Machine | LQT25-95 | Set | SUS | ||||

3 | Picking Line | TJ6000 | Set | SUS | ||||

4 | Hoister | TSJ1700 | Set | SUS | ||||

5 | Potato Cutting Machine | DB-CP | Set | SUS | ||||

6 | Bubble Washing machine | CQX7500 | Set | SUS | ||||

7 | Blanching Line | LPT8500 | Set | SUS | ||||

8 | Cooling and Dewatering Machine | FG8000 | Set | SUS | ||||

9 | Frying Line | WYZ12000 | Set | SUS | ||||

10 | Cooling and Deoiling Line | FG8000 | Set | SUS | ||||

11 | Picking Line | SS6000 | Set | SUS | ||||

12 | Seasoning Line | BL3500 | Set | SUS | ||||

13 | Fully Automatic Packing Machine | DZ420 | Set | SUS | ||||

14 | Fluidized Quick Freezer | SD5000 | Set | SUS | ||||

For more production requirements please contact us, we will customize your production line according to your actual needs, to help you achieve energy efficiency. Our factory provides 1-year free warranty service and free delivery of related accessories at the time of shipment. | ||||||||

Process Flow

Fried Potato Chips Production Line Process Flow:

Hoister with tank→Washing peeling machine→Picking line→Hoister machine→Potato cutter→Rinsing→Blanching and color protection→Rinsing and cooling→Dehydration→Frying machine→Air drying deoiling line→Seasoning machine→Automatic packing machine

Frozen French Fries Production Line Process Flow:

Hoister with tank→Washing peeling machine→Picking line→Hoister machine→Potato cutter→Rinsing→Blanching and color protection→Rinsing and cooling→Dehydration→Frying machine→Air drying deoiling line→Quick freezer→Picking conveyor belt→Automatic packing machine

Fried Banana Chips Production Line Process Flow

peeling machine→Slicing machine→Frying machine→Air drying deoiling line→Automatic packing machine

Product Description

Main Equipment Introduction:

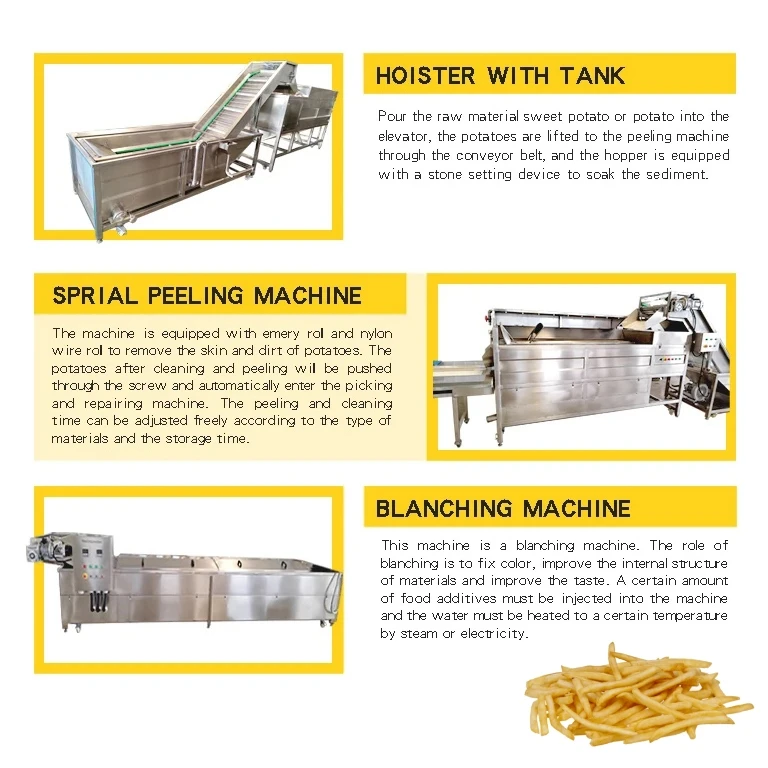

①Hoister with tank:

Pour the raw material sweet potato or potato into the elevator, the potatoes are lifted to the peeling machine through the conveyor belt,and the hopper is equipped with a stone setting device to soak the sediment.

②Spiral peeling machine:

The machine is equipped with an emery roll and nylon wire roll to remove the skin and dirt of potatoes. The potatoes after cleaning and peeling will be pushed through the screw and automatically enter the picking and repairing machine. The peeling and cleaning time can be adjusted freely according to the type of materials and the storage time.

③Blanching machine:

This machine is a blanching machine. The role of blanching is to fix color, improve the internal structure of materials and

improve the taste. A certain amount of food additives must be injected into the machine and the water must be heated to a certain temperature by steam or electricity.

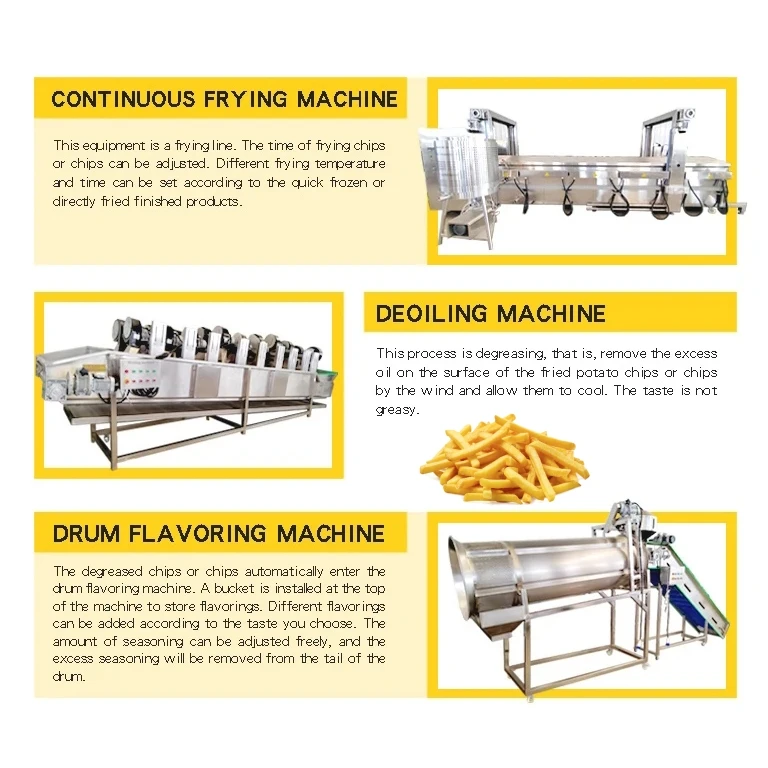

④Continuous frying machine:

This equipment is a frying line. The time of frying chips or chips can be adjusted. Different frying temperature and time can be set according to the quick frozen or directly fried finished products.

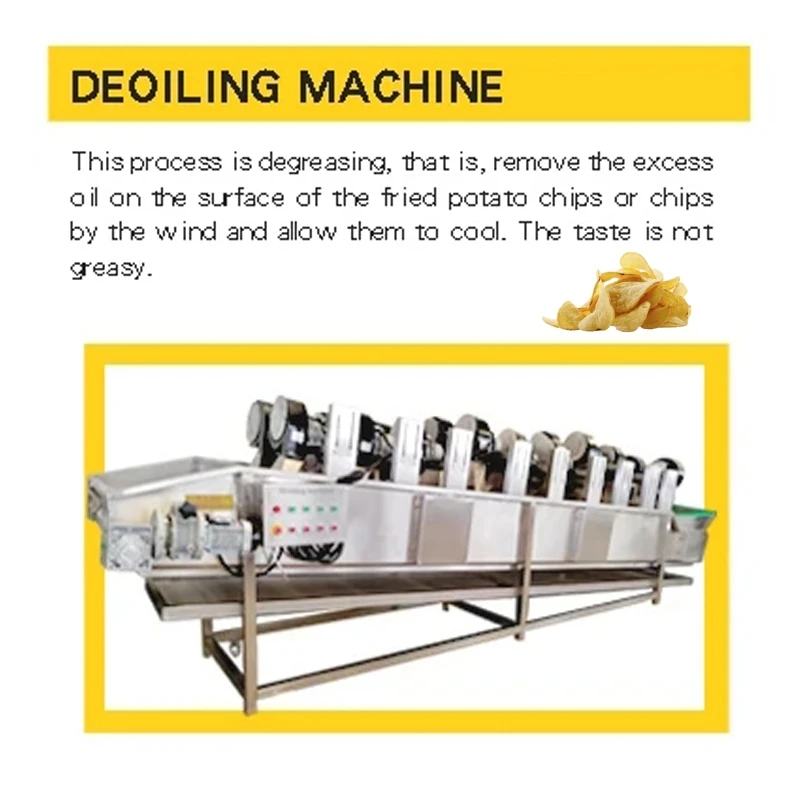

⑤Deoiling machine:

This process is degreasing, that is, remove the excess oil on the surface of the fried potato chips or chips by the wind and allow them to cool. The taste is not greasy.

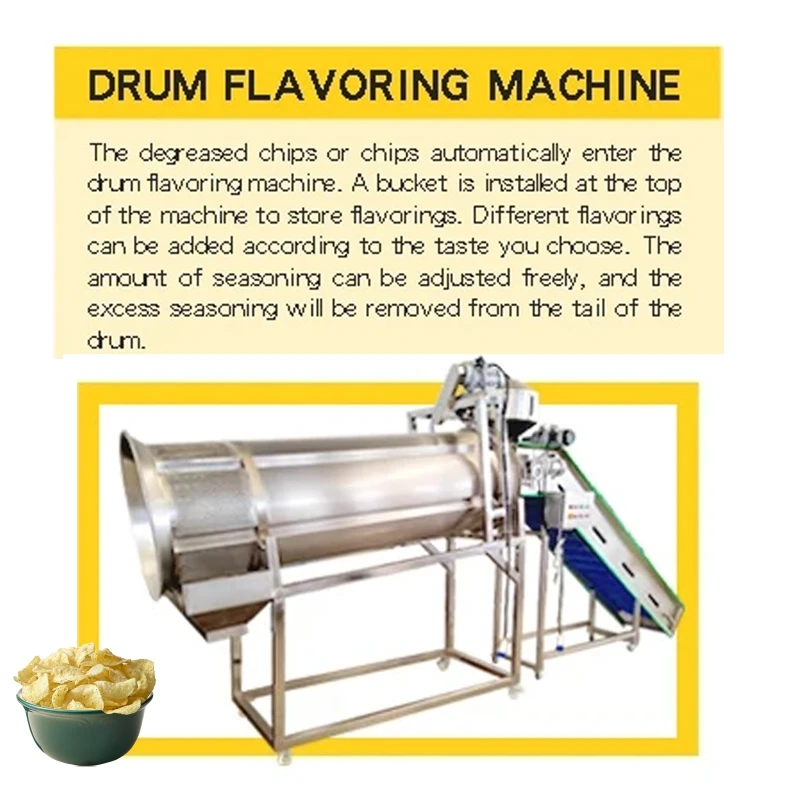

⑥Drum flavoring machine:

The degreased chips or chips automatically enter the drum flavoring machine. A bucket is installed at the top of the machine to store flavorings. Different flavorings can be added according to the taste you choose. The amount of seasoning can be adjusted freely, and the excess seasoning will be removed from the tail of the drum.

②Spiral peeling machine:

The machine is equipped with an emery roll and nylon wire roll to remove the skin and dirt of potatoes. The potatoes after cleaning and peeling will be pushed through the screw and automatically enter the picking and repairing machine. The peeling and cleaning time can be adjusted freely according to the type of materials and the storage time.

③Blanching machine:

This machine is a blanching machine. The role of blanching is to fix color, improve the internal structure of materials and

improve the taste. A certain amount of food additives must be injected into the machine and the water must be heated to a certain temperature by steam or electricity.

④Continuous frying machine:

This equipment is a frying line. The time of frying chips or chips can be adjusted. Different frying temperature and time can be set according to the quick frozen or directly fried finished products.

⑤Deoiling machine:

This process is degreasing, that is, remove the excess oil on the surface of the fried potato chips or chips by the wind and allow them to cool. The taste is not greasy.

⑥Drum flavoring machine:

The degreased chips or chips automatically enter the drum flavoring machine. A bucket is installed at the top of the machine to store flavorings. Different flavorings can be added according to the taste you choose. The amount of seasoning can be adjusted freely, and the excess seasoning will be removed from the tail of the drum.

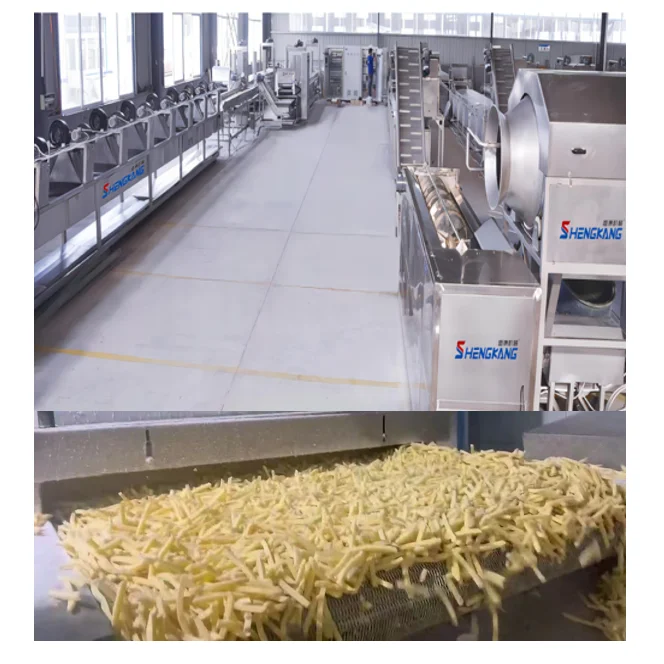

Product Picture

Our Advantages

1. More than 20 years of experience in food machinery production.

2. Years of export experience, and sales in more than 180 countries worldwide.

3. Support customization to meet your needs and solve your problems.

4. Sincere communication, detail control, and considerate service.

2. Years of export experience, and sales in more than 180 countries worldwide.

3. Support customization to meet your needs and solve your problems.

4. Sincere communication, detail control, and considerate service.

We have perfect after-sales service

1. One-year warrantyThe company implements a one-year warranty and a lifetime service system for the products.

2. About the equipment

If the device fails or encounters difficult problems during use, You can first solve it by reading the "Common troubleshooting Method" in the product description.

3. About the service

If the equipment encounters a malfunction and cannot be resolved by itself, please contact us and the company will Respond within 2 hours after receiving the failure notification.

Company Information

Weifang Kelesi Machinery Technology Co., Ltd. is a professional machinery technology enterprise of R & D, manufacturing and sales. It has a factory area of 30,000 square meters, a standardized workshop of 12,000 square meters, and an office area of 5,000 square meters. We focus on the R&D, production, and sales of deep processing equipment for frying lines, vegetables and fruits, aquatic products and meat, and various solutions.

The company specializes in producing: fried potato chips, chips processing equipment, vegetable processing equipment, garlic processing equipment, fruit and vegetable cleaning (peeling) cutting processing equipment, vegetables, and food blanching (green, pasteurization) equipment. Air drying dehydration, deoiling line, frying line, leisure food processing line, aquatic products, meat processing line, and other automation equipment.

Customer Photos

FAQ

1. What can we offer you?

Food machinery and various solutions

2. What are our packing conditions?

We package the goods with film winding and plywood.

3. How can we guarantee the quality?

Our goods are 100% inspected before loading.

4. Why do you buy from us instead of other suppliers?

30 years of food processing experience, each machine processing high quality, advanced machining technology, and good after-sales service.

5. How long is the delivery time of our equipment?

Generally speaking, 30-35 days after receiving the deposit, the specific delivery time depends on the quantity of goods and your order.

6. What are our terms of payment?

50% by telegraphic transfer as a deposit, and 50% before delivery can be negotiated according to the actual situation

Food machinery and various solutions

2. What are our packing conditions?

We package the goods with film winding and plywood.

3. How can we guarantee the quality?

Our goods are 100% inspected before loading.

4. Why do you buy from us instead of other suppliers?

30 years of food processing experience, each machine processing high quality, advanced machining technology, and good after-sales service.

5. How long is the delivery time of our equipment?

Generally speaking, 30-35 days after receiving the deposit, the specific delivery time depends on the quantity of goods and your order.

6. What are our terms of payment?

50% by telegraphic transfer as a deposit, and 50% before delivery can be negotiated according to the actual situation

Contact Us

We Recommend

New Arrivals

New products from manufacturers at wholesale prices