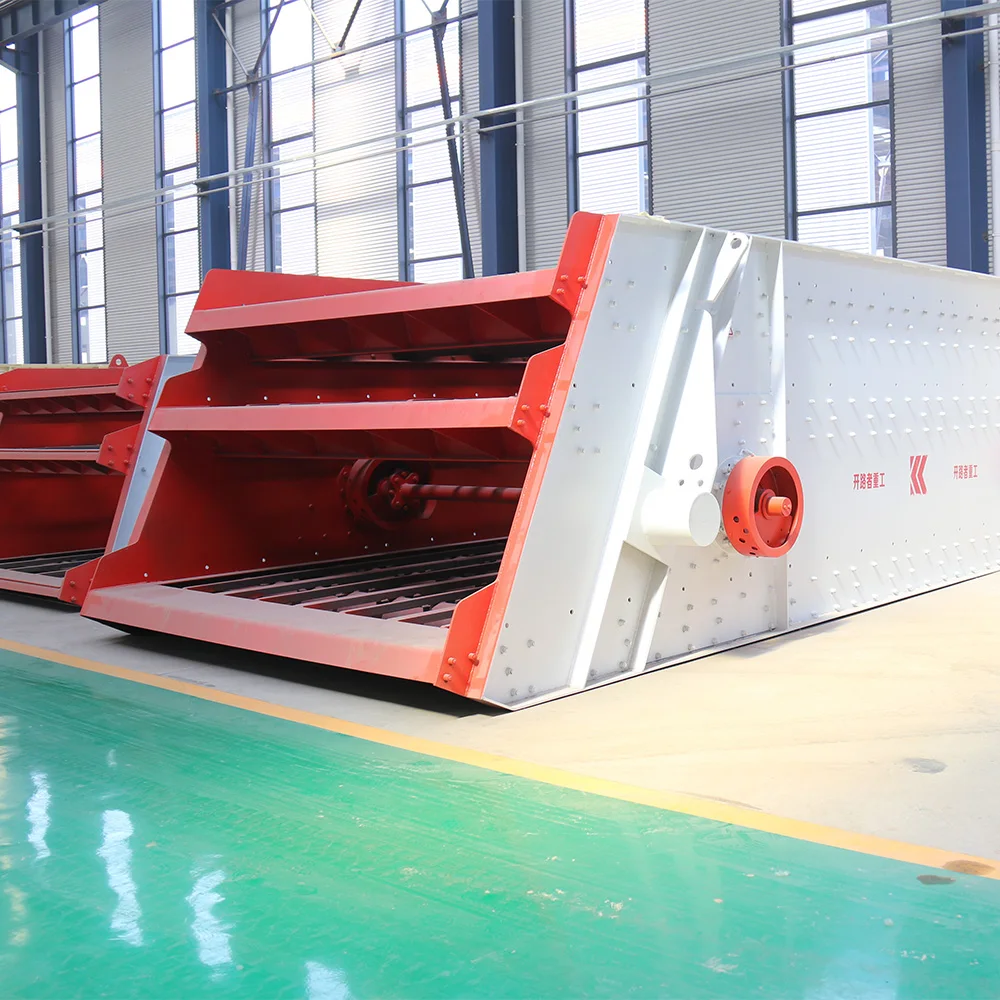

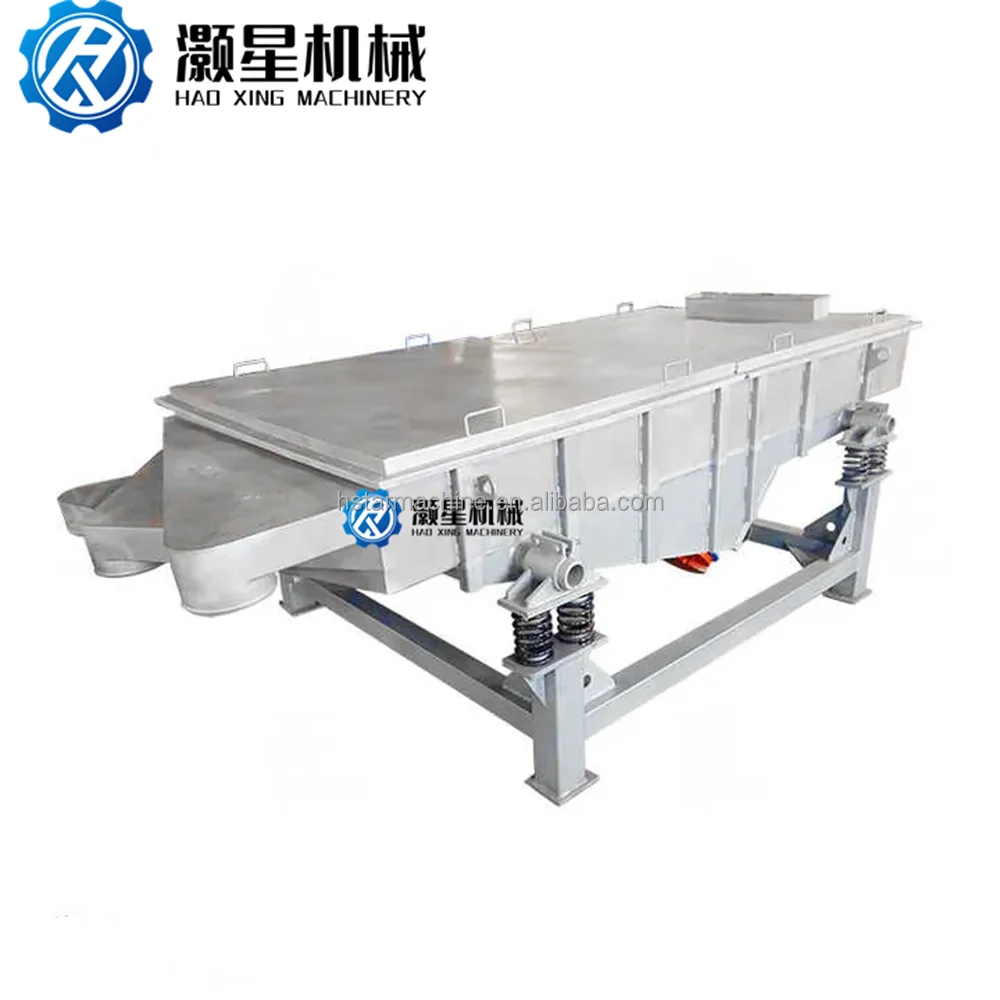

Wholesale High Quality Mobile Trommel Screen Linear Circular Vibrating Screen Topsoil Ore Motor Engine Bearing Gear Gearbox

- Category: >>>

- Supplier: Zhengzhou Sinolion Equipment Co. Ltd.

Share on (1601275326855):

Product Overview

Description

PRODUCT DESCRIPTION

Like all machines in the MTS series, the MTS 0818 not picky about sifting out waste and raw materials regards. It is equally suitable for compost, soil,light rubble, wood, biomass, sand and gravel etc.

Screening materials: earth, sand, gravel, compost, wood chips, construction waste, recycling material, slag, crushed stone and stone in grain sizes from 2 mm to 80 mm.

The basic working principle of the mobile trommel screen: the material is poured into the feed hopper by the loader, and conveyed to the tumbler screen by the conveyor of the feed hopper. Then by the motor reducer through the coupling drive roller rotation drum. The material particles in the drum follow the screen mesh, the drum rotates to a certain height, throws and falls through gravity, and the finished product is filtered through the screen mesh. Finally, the screened materials are transported to different places by different conveyors.Screening materials: earth, sand, gravel, compost, wood chips, construction waste, recycling material, slag, crushed stone and stone in grain sizes from 2 mm to 80 mm.

Advantages

·Quick change system for the sieve insert, optionally drum or star screen insert

·Large 1.2*0.8*0.8 m feed hopper with a loading height of just 1.65 m

·Electronic load control for a perfect screening result optimal throughput

·Perfect mobility thanks to compact transport dimensions

·Quick change system for the sieve insert, optionally drum or star screen insert

·Large 1.2*0.8*0.8 m feed hopper with a loading height of just 1.65 m

·Electronic load control for a perfect screening result optimal throughput

·Perfect mobility thanks to compact transport dimensions

Model | Trommel diameter (MM) | Trommel length (MM) | Capacity (M3/H) | Motor power (KW) | Weight (KG) | Dimensions (L*W*H)(M) |

MTS0818 | 800 | 1800 | ≤15 | 2.4 | 650 | 3.15*1.1*1.65 |

MTS1022 | 1000 | 2200 | ≤30 | 8.2 | 2750 | 4.3*1.9*2.45 |

MTS1230 | 1200 | 3000 | ≤60 | 10.6 | 3210 | 5.4*2.1*2.7 |

MTS1550 | 1500 | 5000 | ≤90 | 20 | 7900 | 9.4*2.2*2.9 |

MTS2050 | 2000 | 5000 | ≤150 | 33.2 | 9300 | 10*2.9*3.95 |

Product Details

The frequency control box controls the drum speed by adjusting the speed of the motor.

Generator provides efficient power, reliable performance and durable construction with low maintenance requirements.

Application

PACKING & DELIVERY

COMPANY INTRODUCTION

Zhengzhou Sinolion Equipment Co. Ltd.

It's a Chinese high-tech company, which is professional in manufacturing trommel sieving equipment, also one of the earliest Chinese enterprises to enter this field. After 30 years of development, Sinolion has been now setting up branches,integrating engineering,trade research and development, production and sales, developed to be a large-scale enterprise. Sinolion has modern standard workshops,as well as advanced technology and testing equipment.

Now, sieving equipment are renowned in domestic and foreign markets,and Sinolion products have been exported to Serbia, United Kingdom, Turkey, Malaysia, Indonesia, Kazakhstan, Vietnam, Egypt, Mexico, Ghana, Tanzania, Nigeria, South Africa, Chile, Bolivia, Canada and other countries. Sinolion provides space planning and design,equipment installation and commissioning support under holding the concept of "To survive with quality and develop with credit". Sinolion strives to build a brand enterprise with satisfaction of customers. Let customers buy reassured and use comfortably! Widely cooperate with relevant institutions to continuously improve product value and performance.For users who ask us to design, manufacture and install products, will provide satisfactory products with the latest technology, reliable quality, favorable price and perfect service. We warmly welcome cooperations with friends from all around the world!

Why Choose Us

FAQ

Q:What materials can the equipment screen?

A:Our mobile trommel screen can screen compost, topsoil,sand, gravel, cow and sheep manure etc.It can be used in many scenarios.

Q:How is the equipment transported?

A: MTS0818 uses wooden box packaging for transportation.Before shipment,it is package in wooden boxes and moisture-proof and rustproof treatmentis performed to prevent rustand corrosion of the equipment during transportation. MTS1022 and MTS1230 require a 20GP container for transportation,A 40HQ can hold 2 set MTS1230s and a 40HQ container can hold 3 set MTS1022s. MTS1550 requires one 40HQ container for transportation.

Q:What kind of power can the equipment provide?

A: Currently, our equipment supports motor type, diesel engine type and diesel generator set type. Three types are optional to meet your various needs.

Q:What are the biggest highlights of the equipment?

A: First, our side conveyor belt uses a herringbone belt which can prevent materials from slipping during conveying materials. The conveyor belt thickness is 11mm for better quality. Secondly,the cleaning brushes use nylon material which is very wear-resistant.According to different models.the brush diameter is between 200-350mm. At the same time, the cleaning brushes can prevent sticky materials from blocking the sieve holes.

Q: Can you give me a solution and quotation?

A:Our mobile trommel screen can screen compost, topsoil,sand, gravel, cow and sheep manure etc.It can be used in many scenarios.

Q:How is the equipment transported?

A: MTS0818 uses wooden box packaging for transportation.Before shipment,it is package in wooden boxes and moisture-proof and rustproof treatmentis performed to prevent rustand corrosion of the equipment during transportation. MTS1022 and MTS1230 require a 20GP container for transportation,A 40HQ can hold 2 set MTS1230s and a 40HQ container can hold 3 set MTS1022s. MTS1550 requires one 40HQ container for transportation.

Q:What kind of power can the equipment provide?

A: Currently, our equipment supports motor type, diesel engine type and diesel generator set type. Three types are optional to meet your various needs.

Q:What are the biggest highlights of the equipment?

A: First, our side conveyor belt uses a herringbone belt which can prevent materials from slipping during conveying materials. The conveyor belt thickness is 11mm for better quality. Secondly,the cleaning brushes use nylon material which is very wear-resistant.According to different models.the brush diameter is between 200-350mm. At the same time, the cleaning brushes can prevent sticky materials from blocking the sieve holes.

Q: Can you give me a solution and quotation?

A: Absolutely sure, we can provide accurate solution and quotation, please give us background information, including raw material, the capacity, max. input size, the output size, the usage of final products, etc.

Q: After order equipment how do we slove the equipment installing?

A: For a small single equipment, we offer you user manual, customer wIll install and commissioning as operating introduction; For a complete production line, we will send our engineer to your workplace to help you install and commissioning until machines work normally. Sinolion has several experienced technicians with passports ready to go for installation, when installation service is needed, the client should pay for technicians' round way air tickets, salary(shall be confirmed before leaving), food and lodging, most importantly to guarantee the technicians' safety.

Q:What's the delivery time after I pay the deposit?

A:We will clear delivery time in sales contract, Single movable drum sieve often deliveried within 10-15 working days after receipt of the pre-payment. Complete production line will delivery within 25-40 working days after receipt of the pre-payment.

Q:How long of your machine quality guarantee terms ?

A:Quality guarantee time is one year(wearing parts excluded).

Q: After order equipment how do we slove the equipment installing?

A: For a small single equipment, we offer you user manual, customer wIll install and commissioning as operating introduction; For a complete production line, we will send our engineer to your workplace to help you install and commissioning until machines work normally. Sinolion has several experienced technicians with passports ready to go for installation, when installation service is needed, the client should pay for technicians' round way air tickets, salary(shall be confirmed before leaving), food and lodging, most importantly to guarantee the technicians' safety.

Q:What's the delivery time after I pay the deposit?

A:We will clear delivery time in sales contract, Single movable drum sieve often deliveried within 10-15 working days after receipt of the pre-payment. Complete production line will delivery within 25-40 working days after receipt of the pre-payment.

Q:How long of your machine quality guarantee terms ?

A:Quality guarantee time is one year(wearing parts excluded).

We Recommend

Electro Vibrating Feeder Conveyor and Vibrating Screen

$3,200.00-3,500.00

Battery Carbon Powder Recycle Ultrasonic Vibrating Sieve Machine

$1,800.00-2,000.00

New Arrivals

New products from manufacturers at wholesale prices