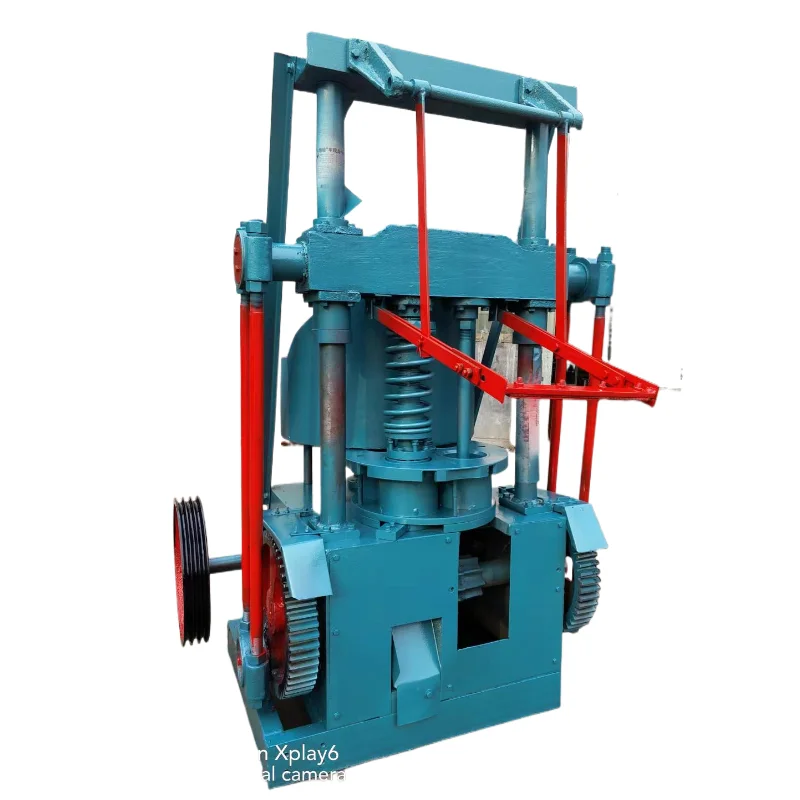

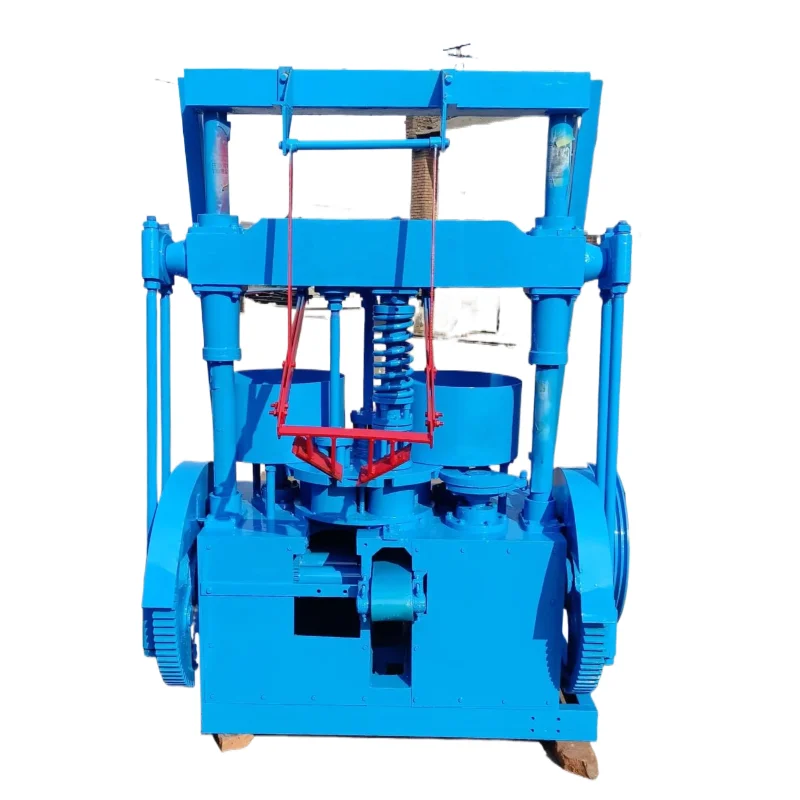

Low Price High Quality Charcoal Making Machine Charcoal Powder Coal Powder Ball Press Machine

- Category: >>>

- Supplier: Lerford Machine LLC

Share on (1601275484525):

Product Overview

Description

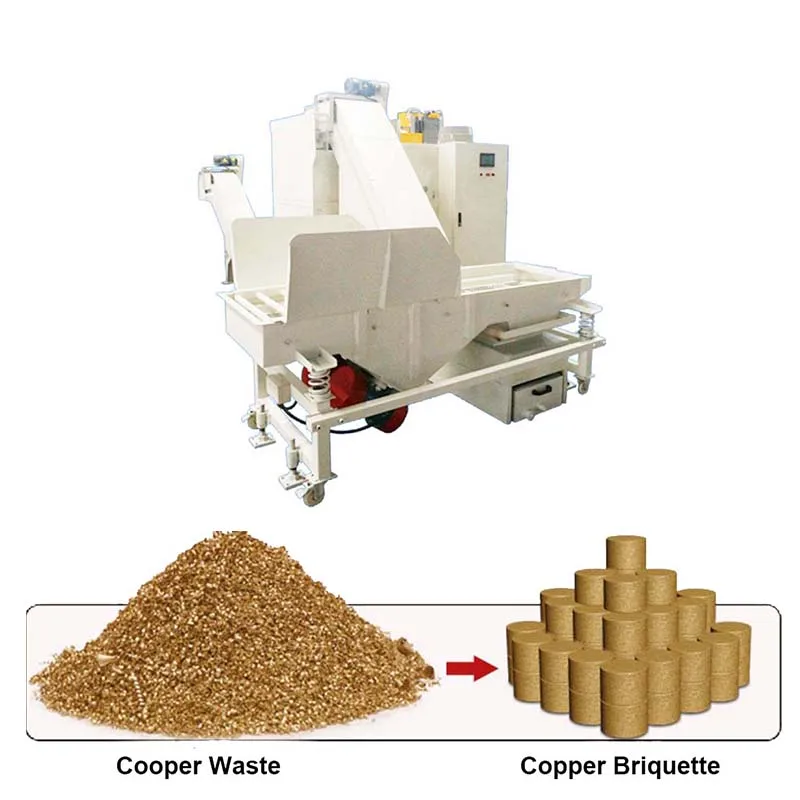

The charcoal briquette machine is a machine that makes charcoal and other biomass fuels into spherical briquettes. The machine can make various biomass fuels, such as sawdust, rice husks, wheat straw, peanut shells, etc., into briquettes with a diameter of 10-80mm, which are used in heating, hot water production and other fields.

Working principle of coal briquette machine

The working principle of coal briquette machine is to compress the biomass particles into a spherical shape after pretreatment, and then dry and solidify them to form finished briquettes.

1. Pretreatment: The biomass particles are crushed for the first time to facilitate the next step of briquetting operation;

2. Bricking operation: Press the pretreated particles into the briquette machine, and the spiral push rod in the machine squeezes the particles into a spherical shape;

3. Take out the finished product: Finally, take out the finished briquettes from the machine, and then pack and transport them as needed.

Advantages of coal ball press machine

1. High efficiency: The coal ball press machine has a fast ball making speed, thousands of balls per minute, which greatly increases the output of coal balls;

2. Environmental protection: The coal balls made by the coal ball press machine reduce the emission of coal powder and plastic and other substances, and have a good protective effect on the environment;

3. Economic: The coal ball press machine has low energy consumption and low cost of use;

4. Simple operation: The coal ball press machine is easy to operate and easy to master.

Structural features of charcoal balls pressing machine

The coal ball machine is mainly composed of a feeder, a ball making machine, a pressing wheel, a pressure regulating reducer, an electronic control cabinet and a storage box.

1. Feeder: The biomass particles enter the feeder and are sent into the coal ball machine through the transmission device.

2. Ball making machine: The propulsion rod squeezes the particles into a spherical shape, and the spherical particles are discharged through the discharge port.

3. Pressing wheel: In order to ensure the uniformity of the spherical particles, a pressing wheel is provided in the coal ball machine to compact the coal balls.

4. Voltage-regulating reducer: This device is a key component for adjusting the briquette pressing speed and motor torque.

5. Electronic control cabinet: The electronic control system controls the operation, maintenance and care of the briquette machine, and can realize automatic operation.

6. Storage box: In order to further improve the storage capacity of briquette and the intelligence of the production line, the briquette machine is equipped with a storage box.

Application and raw materials of briquette machine

1. Application: Charcoal briquette machine is widely used in various industrial fields, such as industrial boilers, home heating, biomass power generation, aquaculture heating, etc.

2. Raw materials: Biomass fuel is the raw material of briquette machine, including wood, sawdust, rice, wheat straw, peanut shells, etc.

Technical information

Model | Biggest Diameter of final product (mm) | Productivity (PC/H) | Motor | Weight | Size(m) |

WSI-125 | 120mm | 2900 | 7.5kw | 0.8T | 1*1.2*1.8m+3*0.3*0.5m |

WSI-140 | 140mm | 3000 | 11kw | 0.95T | 1*1.4*1.8m+3*0.3*0.5m |

WSI-150 | 150mm | 3000 | 15kw | 1.6T | 1.1*1.2*1.8m+3*0.3*0.5m |

WSI-160 | 160mm | 2500 | 15kw | 1.8T | 1.2*1.2*2m+3*0.3*0.5m |

WSI-220 | 220mm | 1600 | 18.5kw | 2.2T | 2.2*2.2*2.2m+3*0.3*0.5m |

WSI-240 | 240mm | 1200 | 22kw | 3.2 | 2.4*1.6*2.2m+3*0.3*0.5m |

How to choose the right machine?

1. Raw materials: You should consider the type of raw materials to be used in the machine. Different machines are designed to handle different types of raw materials.

2. Capacity: You should consider the capacity of the machine you need. You should choose a machine that can handle the amount of material you plan to process.

3. Quality: You should consider the quality of the machine you plan to buy. The quality of the machine affects the durability and efficiency of the machine.

4. Price: You should consider the price of the machine you plan to buy. You should choose a machine that fits your budget, but remember that the price should not compromise the quality of the machine.

What are the pre-sales and after-sales services of our factory?

Pre-sales service:

1. The professional sales team provides professional advice to customers and helps customers choose the right machine.

2. Provide free raw material samples for customers to test the machine.

3. Provide production line design and customized solutions according to customer requirements.

After-sales service:

1. Product warranty: All introduced equipment has a manufacturer's warranty period, and if there are quality problems during the warranty period, they will receive repair services;

2. Installation and commissioning: The seller assembles and commissions the equipment and conducts operation training for customers to ensure that customers can operate the equipment correctly, safely and stably;

3. Safety training: Prepare appropriate safety items for customers, and implement safety management training to ensure the safety of the workplace;

4. One-to-one tracking: In order to better and timely understand the actual use of customers and ensure efficient and timely after-sales service, we will assign a dedicated person to track the feedback every day.

How do we ensure the quality of machine products?

1. Historical experience: We have rich experience in machine manufacturing. Each equipment is carefully manufactured by professional workers to ensure the precision and quality of each component.

2. Mature technology: We use various machine tools, tools and other modern production equipment to ensure the quality and precision of the finished product.

3. Reasonable quality inspection mechanism: Strictly follow the national quality inspection standards for inspection and acceptance. Strict quality control must be carried out in every link from purchasing materials to finished product delivery and project establishment to ensure the quality of each product.

4. Quality assurance: We have a strict quality assurance system for each equipment, including standardized operation, maintenance and management, to ensure long-term stable operation.

What is our delivery process?

1. After the customer places an order, our sales team will arrange the delivery according to the customer's requirements.

2. We will provide customers with delivery information, including delivery date, delivery route and delivery time.

3. We will ensure that the machine is properly packaged to prevent damage during transportation.

Why choose our company's machine?

1. Our company has more than ten years of experience in producing charcoal machines, and its products are exported to many countries and regions.

2. Our company has a professional R&D team and produces high-quality machines.

3. Our machines are easy to operate and maintain, and we provide lifelong technical support and maintenance services.

4. We provide customized solutions according to customer needs to ensure the best results.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices