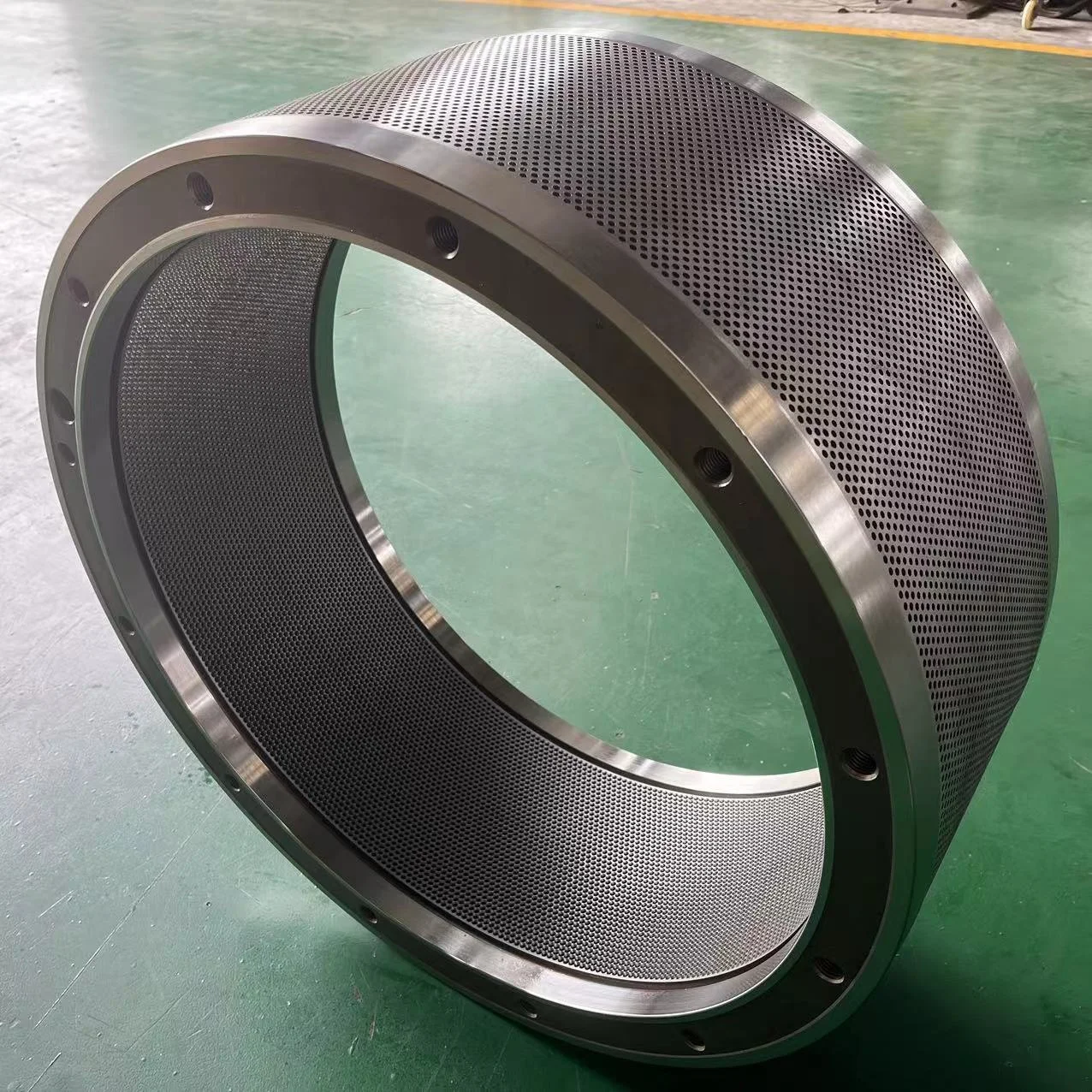

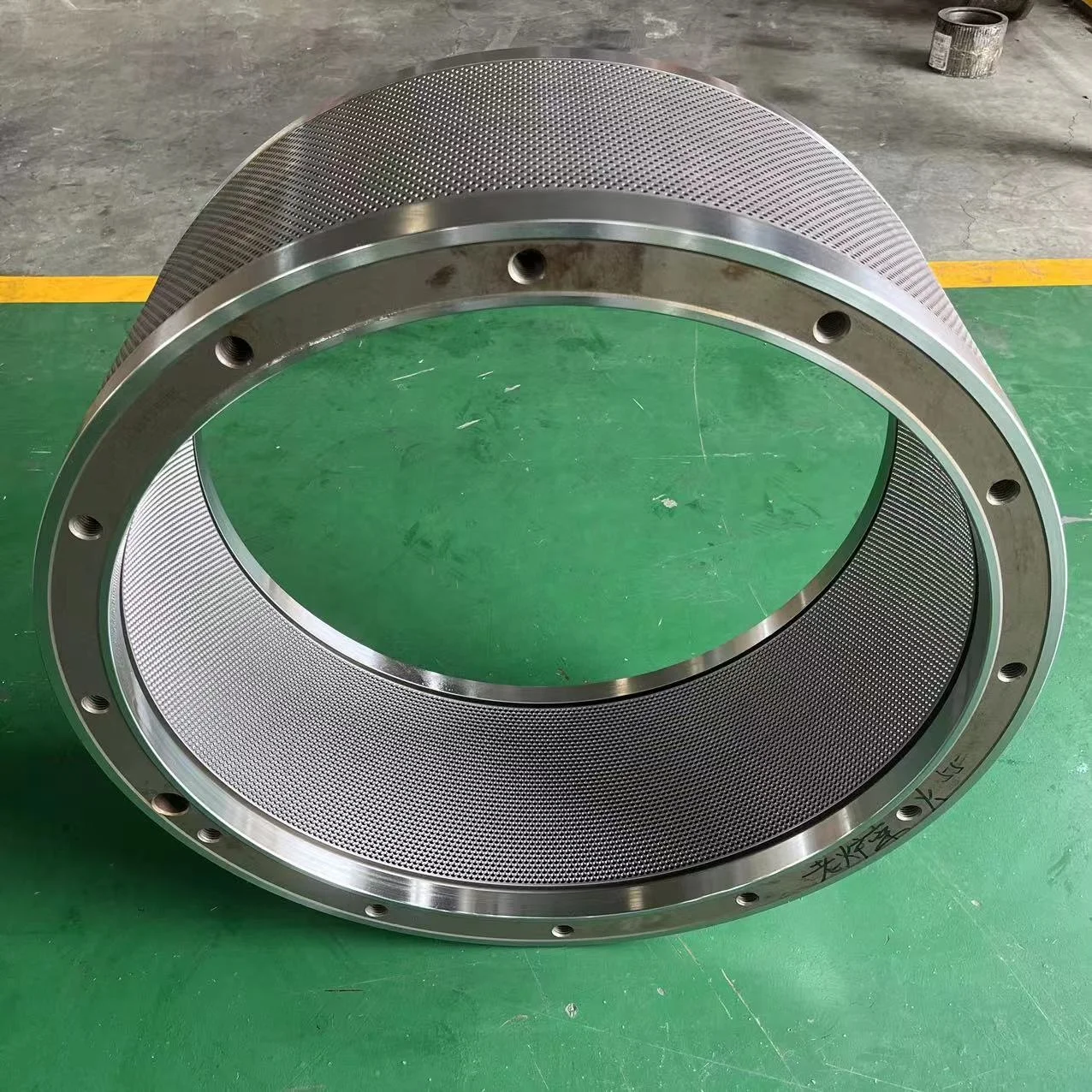

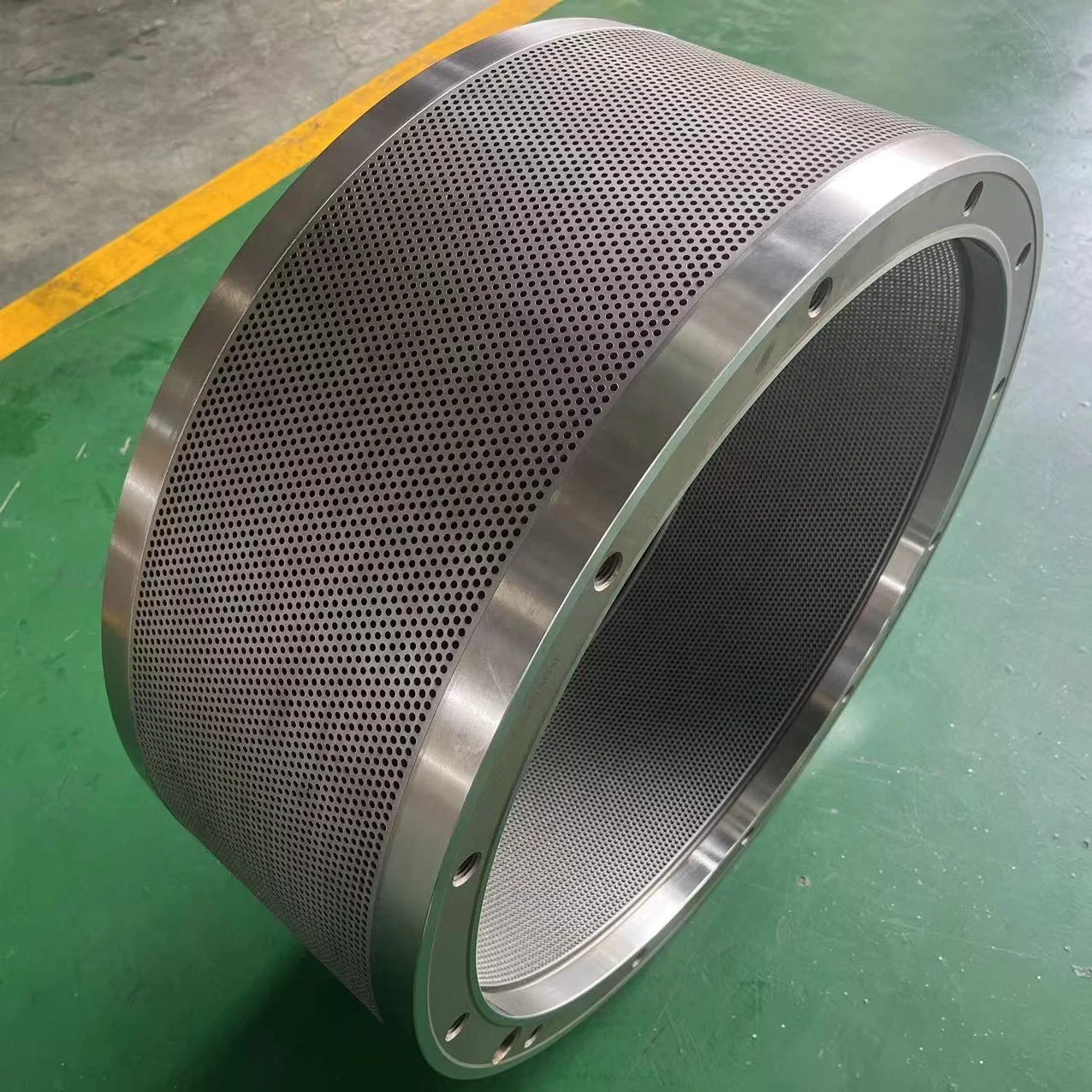

Prime quality Low price X46Cr13 ring die 660/230 factory directly for chicken duck feed pellet palletizer Matrix disc 660 230

- Category: >>>

- Supplier: Liyang Winho Machinery Co. Ltd.

Share on (1601276913461):

Product Overview

Description

Prime quality Low price X46Cr13 ring die 660/230 factory

directly for chicken duck feed pellet palletizer Matrix disc 660-230

| Brand | Model | Inner Diameter | Outer Diameter | Total Width | Material | HRC | Hole Diameter |

| TIANHER | 660-230 | 660 | 770 | 300 | Stainless steel(X46Cr13) | 52-55 | φ1-25 |

| Stainless steel(X46Cr13) | 52-55 | φ1-25 | |||||

| Stainless steel(X46Cr13) | 52-55 | φ1-25 | |||||

| Stainless steel(X46Cr13) | 52-55 | φ1-25 | |||||

| Stainless steel(X46Cr13) | 52-55 | φ1-25 |

Liyang Winho Machinery Co., Ltd. is the leading manufacturer of

feed pellet and wood pellet ring dies for the world's top pellet brands.

Our wood chippers are also industry-leading. Annually, we deliver

8,000-10,000 high-quality dies to customers worldwide.

As a direct factory,we pride ourselves on our high capacity, superior quality, competitive pricing, and fast delivery.

Our meticulous production process includes precision material lathing,

hole drilling, expert countersinking, precise heat treatment, perfect

polishing, HRC testing, rigorous quality checks, careful packaging, and

prompt delivery. We look forward to collaborating

with you; your trust is our greatest honor.

1.Raw Material and Rough Lathing:

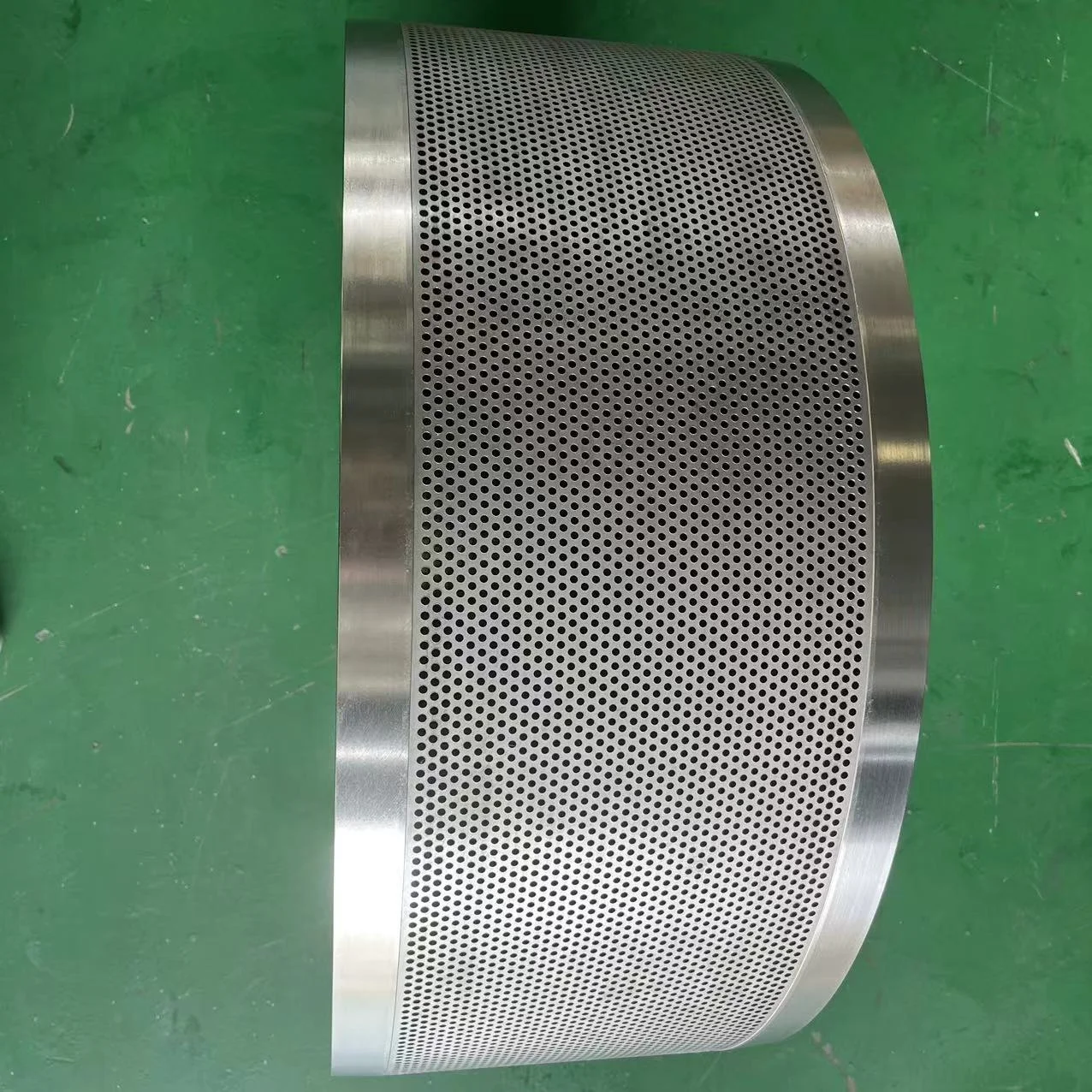

2. Hole Drilling for Ring die by gun drill machines

( We have 40pcs gun drills machines):

3.Screw hole drilling:

4.Automatic Countersinking for Ring die :

5.Vaccum Hot Stove for Ring die/Pellet die Heat

treatment:

6.Fine Lathing:

7.Packging:

1. What types of pellet machines are your dies compatible

with?

- Our dies are compatible with various types of pellet machines, including

wood pellet mills, feed pelletizers, etc., and can be customized to meet

specific needs.

2. What is the lifespan of your dies, and how can I extend

their lifespan ?

- The lifespan of our dies depends on factors such as material quality,

usage, and maintenance. Regular cleaning, proper usage, and correct

installation can extend their lifespan.

3. What is the process for producing customized dies?

- Producing customized dies involves design, manufacturing, and testing

according to the customer's requirements to meet specific production needs.

4. What materials are available for the dies, and what are

the pros and cons of each?

- We offer dies in various materials such as alloy steel, stainless steel,

each with its advantages. Alloy steel is wear-resistant but relatively

expensive, while stainless steel is corrosion-resistant but with lower

hardness.

5. How do I select the right size of die for specific

production needs?

- We provide tailored size recommendations based on customer

production requirements and machine specifications.

6. What is the production lead time for dies, and do

you offer expedited delivery?

- The production lead time depends on customization but typically

takes several weeks. For urgent needs, we endeavor to provide

expedited production services.

7. What maintenance advice do you provide for your

dies?

- Regularly clean the die surface, avoid excessive wear, use it

reasonably, and perform routine maintenance checks.

8. How do you ensure the quality and consistency

of dies during the manufacturing process?

- We employ advanced processes and stringent quality control

to ensure each die meets high-quality standards.

9. Can you offer guidance on installing, replacing,

and adjusting dies?

- Yes, we provide detailed installation, replacement, and

adjustment guidelines to ensure correct use of the dies.

10. What factors contribute to the cost structure

of dies, and what influences their costs?

- Die costs are influenced by factors such as material choice,

size, and complexity of customization requirements. Common

cost-influencing factors include material selection, size, and

the degree of customization needed.

Above are part of the common questions, if you

have any other question, feel free to consult!

Our Slogan!!!

Embrace Superiority, Embody Quality: Our Commitment

to Crafting Exceptional Pellet Ring Dies Every Time! With an unwavering

dedication to precision engineering, we assure you of top-tier quality,

competitive pricing, and swift deliveries.

Trust us to fulfill your needs with the pinnacle of excellence in pellet

ring dies.

Contact : Andy Ma

Mobile/wechat/whatsapp:+ 86 19856302985

Instagram: andy1mar

Facebook: Andy Ma

Liyang Winho machinery Co.,Ltd (www.winhomachinery.com)With

30 years of expertise in die production, we stand as China's

premier manufacturer, delivering unrivaled top-quality ring dies.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices