Hot selling cement mill vertical mill supplier for sale in ore industry/PFRM vertical ball mill price

- Category: >>>

- Supplier: Jiangsu Lafa International Engineering Group Co. Ltd.Jiangsu Ltd.

Share on (1601277522529):

Product Overview

Description

Overview

Capacity: 20 t/d-400 t/d

Main Materials: Limestone,Clay,Gypsum,Fly Ash,Slag

Main Equipment: Cement Mill,Cement Kiln,Bag Filter

Application: Cement Clinker Grinding Station

Main Materials: Limestone,Clay,Gypsum,Fly Ash,Slag

Main Equipment: Cement Mill,Cement Kiln,Bag Filter

Application: Cement Clinker Grinding Station

Product Description

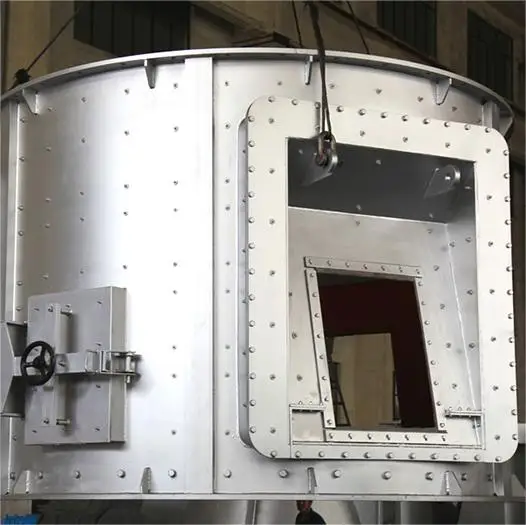

HRM and PRM vertical mill

HRM and PRM vertical mill grind materials(0-44mm) to related fineness by grinding rollers. This equipment has high grinding efficiency and high drying capacity, and you can easy adjusting your product fineness, and this equipment has low noise, low power consumption and simple process, less wear lost and save investment.

And vertical mill is consist of separator, grinding roller, grinding table, pressure loading device, reducer, motor, shell and

etc.

And vertical mill is consist of separator, grinding roller, grinding table, pressure loading device, reducer, motor, shell and

etc.

Advantages

1. It can save 20-50% power consumption than ball mill;

2. Special designed for cement, slag and mixed cement;

3. Stable operation, and high production efficiency;

4. Easy maintenance and low maintenance cost;

5. It can grind slag and mixed cement with high moisture;

6. Guarantee the stable quality of cement and it is easy for adjusting quality;

7. Long lifetime;

8. Mill is designed simple and tight;

9. Mature and reliable technology

2. Special designed for cement, slag and mixed cement;

3. Stable operation, and high production efficiency;

4. Easy maintenance and low maintenance cost;

5. It can grind slag and mixed cement with high moisture;

6. Guarantee the stable quality of cement and it is easy for adjusting quality;

7. Long lifetime;

8. Mill is designed simple and tight;

9. Mature and reliable technology

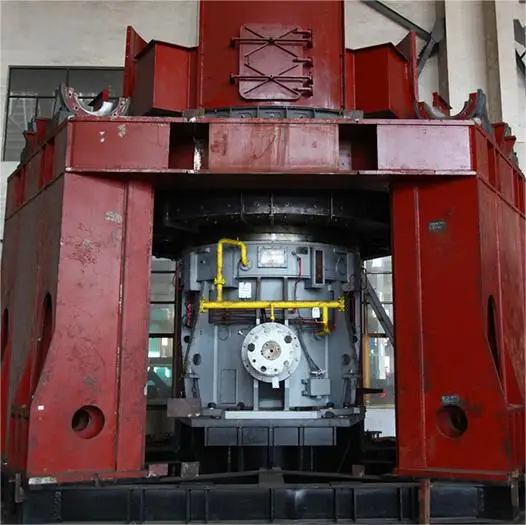

Working Principle

The vertical mill is mainly composed of powder concentrator, grinding roller device, grinding disc device, pressurizing device, reducer, motor, shell, etc. The separator is an efficient and energy-saving powder separation device. The grinding roller is a component used to roll and crush materials. The grinding disc is fixed on the output shaft of the reducer, which is the place where the grinding roller rolls materials. The pressurization device is a component that provides grinding pressure for the grinding roller and provides sufficient pressure to the grinding roller to crush materials. After being crushed by hammer crusher, the large material becomes smaller and is sent to the storage hopper by elevator, and evenly sent to the distribution board on the steering board through vibrating feeder and inclined feeding pipe. The grinding disc is driven by a motor through a reducer. The material falls from the feed opening onto the grinding plate. The material is driven to the edge of the disc by centrifugal force and crushed into fine powder by roller. Then, the hot air of the nozzle converts the fine powder into efficient classification.

The qualified powder is brought to the powder collector through air for collection, and the unqualified powder is sent back for regrinding.

The qualified powder is brought to the powder collector through air for collection, and the unqualified powder is sent back for regrinding.

Product Specifications

Company Profile

We Recommend

China new 100T Cement Silo for hot sale

US $7533-$8133

Lime Cement Dolomite Rotary Oven Furnace

US $5000-$1000000

Multi-stage Lime Slaker for Calcium Hydroxide Production Plant

US $70000-$200000

New Arrivals

New products from manufacturers at wholesale prices