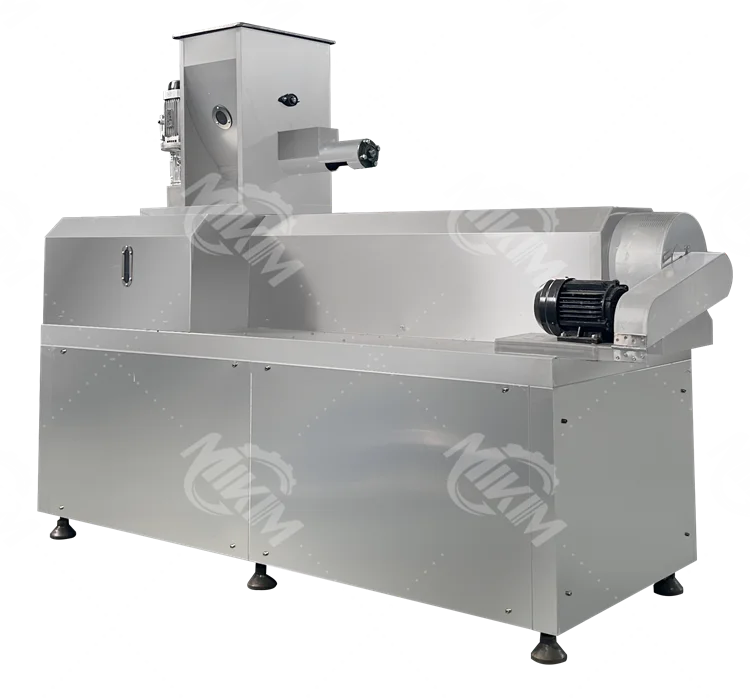

Stainless Steel Double Screw Extruder Machine for Floating/Sinking Fish Feed for Home Use Poultry Farm Manufacturing Industries

- Category: >>>

- Supplier: MIKIM TECHNIQUE LLCMIKIM LLC

Share on (1601277579572):

Product Overview

Description

Products Description

Puff snack food has become increasingly popular with the fast-paced lifestyles of people today. Puffed snacks are light and fluffy snacks that are highly addictive and can be consumed at any time of the day. These snacks can be made from a variety of grains such as corn, wheat, rice,oats, and potatoes, and are available in various shapes and flavors.

One of the most popular puff snack food is corn puffs. Corn puff extruder machines are essential equipment for making corn puff snacks. These extruders use the process of extrusion to transform corn meal into corn puff snacks. The extrusion process produces puffed snacks that are crispy and crunchy, and have a unique texture and flavor.

Model | Power | Capacity | Heater | Dimension(mm) | Weight |

LYS-65 | 5.5kw | 50 kg/h | 1 kw | 1720*870*1050 | 350 kg |

LYS-70 | 15kw | 150kg/h | 1 kw | 1720*970*1250 | 500 kg |

LYS-85 | 18.5kw | 200-300kg/h | 2 kw | 1360*1870*850 | 650 kg |

LYS-95 | 22kw | 400-500kg/h | 2 kw | 2300*1170*1400 | 850 kg |

Snack Food Extruder Feature:1. This snack extruder making machine can be used for different areas such as people food industry,pet food industry etc.

2. Through friction of screw and barrel, the grains are cooked in the extruder. Forming is at the die face cutter. The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring, fruit loop, star, wheel and flower etc.

3. This corn puffing machine is with slight weight, compact structure, easy to be operated.

4. It is a new type and suitable for rice, maize, sorghum, yellow rice, flour and so on.

5. This corn snack food extruder can produce different shapes with different moulds such as cylinder shape, round sphere, millet beautiful form, lotus root shape and various shapes.

6.Final rice or corn puffed produce can be flavored by way of adding food safe additive, such as Sodium cyclamate, salt, spice, or others.

Details Images

Twin Screw Corn Puffed Snack Extruder

Corn puff snacks food machine is a new type of extruding food machine studied and developed by ourselves on the basis of learning from advanced technology in the world so that its technical performance and quality of products both reach to the most advanced in the world. This line will finish mixing, extruding, cutting, spraying, and producing in onepass operation automatically. This has features of lots of types, flexible collocation, extensive applied materials, various products and easy operation

Main Features

1)Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4)Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Flow chart : Grinding→mixing→extruding→drying→flavoring→cooling→packaging

Model | Main Power | Cutter Power | Feeder Power | Capacity t/h | Weight |

GSP-70 | 22kw | 1.5kw | 2.2kw | 0.15-0.2 | 500 kg |

GSP-80 | 30kw | 1.5kw | 2.2kw | 0.25-0.3 | 650 kg |

GSP-85 | 37kw | 1.5kw | 2.2kw | 0.35-0.5 | 850 kg |

Related Products

Fish Feed Extruder Feature:

1.This fish feed machine is pellet feed extrusion equipment. Fish food, cat food, dog food and other pet feed extruder. Various patterns can be produced, and the molds can be customized according to requirements.

2. The product discharge port is equipped with frequency conversion speed control rotary cutting device, which can be arbitrarily adjusted blade speed, control cutting speed and length

3. This fish feed equipment takes corn, soybean (bean cake) and other animal scraps as raw materials, which can be directly added to the machine to produce different pellets with novel shape, unique taste, rich nutrition and fine organization. Suitable for dogs, cats, fish, birds, rabbits, shrimps, etc.

4. If the raw material is in powder form, it can be made into granule directly; if the raw material is in granule form, it should be crushed into powder less than 3mm first.

5. Raw material moisture also has certain requirements, if less than 30%, it is better.

Model | 40 | 60 | 70 | 80 |

Power | 5.5KW | 15KW | 18.5KW | 22KW |

Capacity | 120-150 | 180-220 | 240-300 | 400-500 |

Weight | 350KG | 450KG | 500KG | 580KG |

Size(mm) | 1500*1100*1100 | 1600*1300*1250 | 1600*1300*1250 | 1800*1400*1350 |

Model | 100 | 120 | 135 | 160 |

Power | 37KW | 55KW | 75KW | 90KW |

Capacity | 700-1000 | 1200-1500 | 1500-1800 | 2000-2400 |

Weight | 750KG | 850KG | 950KG | 1200KG |

Size(mm) | 1970*2900*1150 | 2200*2900*1200 | 2350*2900*1200 | 2350*2900*1400 |

Export to Nigeria. Fish Feed Production Plant 300kg/h

Mixer machine+Bucket Elevator+ wet type extruder+dryer machine +drum flavor machine

Export to Indonesia

Fish Feed Production Plant 500kg/h

Export to Canada

Fish Feed Production Plant 500kg/h

Export To Korea 1t/h Fish Feed Production Plant

1 t/h Fish Feed Production Plant all in stainless steel material

SS Conveyor+SS Mixer Machine +SS Conveyor + Fish feed Extruder + Output Cooling Conveyor

Company Profile

We Recommend

New Arrivals

New products from manufacturers at wholesale prices