Laboao Ceramic Fiber Muffle Furnace LMFC 18 Precision Heating up to 1800C 4L

- Category: >>>

- Supplier: Zhengzhou Laboao Instrument Equipment Co. Ltd.

Share on (1601277750459):

Product Overview

Description

Product Details

The Ceramic Fiber Muffle Furnace (LMFC 1800°C) series is designed for precisely controlled applications such as sintering, melting, element analysis, and physical determination within a temperature range of 300 to 1800°C. With an accuracy of ±1°C in temperature distribution, this box-type resistance furnace, also known as a muffle furnace, serves as fundamental heating equipment in laboratories across various sectors. Its widespread usage in industrial, mining, aviation, aerospace, research institutes, and universities underscores its importance for tasks like sintering, melting, heat treatment, and the analysis of volatile substances. Available in different volumes (2L, 7L, 16L, 24L, 36L), this furnace series combines reliability and versatility to meet diverse experimental and laboratory needs.

Model | Single segment type(D) | LMFC-2-18D | LMFC-4-18D | LMFC-8-18D | LMFC-12-18D | |||||

Program type(P) | LMFC-2-18P | LMFC-4-18P | LMFC-8-18P | LMFC-12-18P | ||||||

Touch type(T) | LMFC-2-18T | LMFC-4-18T | LMFC-8-18T | LMFC-12-18T | ||||||

Performance | Temperature Range | Long-term use: 1780℃; maximum use of 1800℃ for two hours; auto-tuning maximum setting temperature is 1700℃ | ||||||||

Temperature Resolution | 1℃ | |||||||||

Temperature Uniformity | ±1℃ | |||||||||

Heating-up Time | ≤60min | |||||||||

Structure | Shell | Spraying cold rolled steel | ||||||||

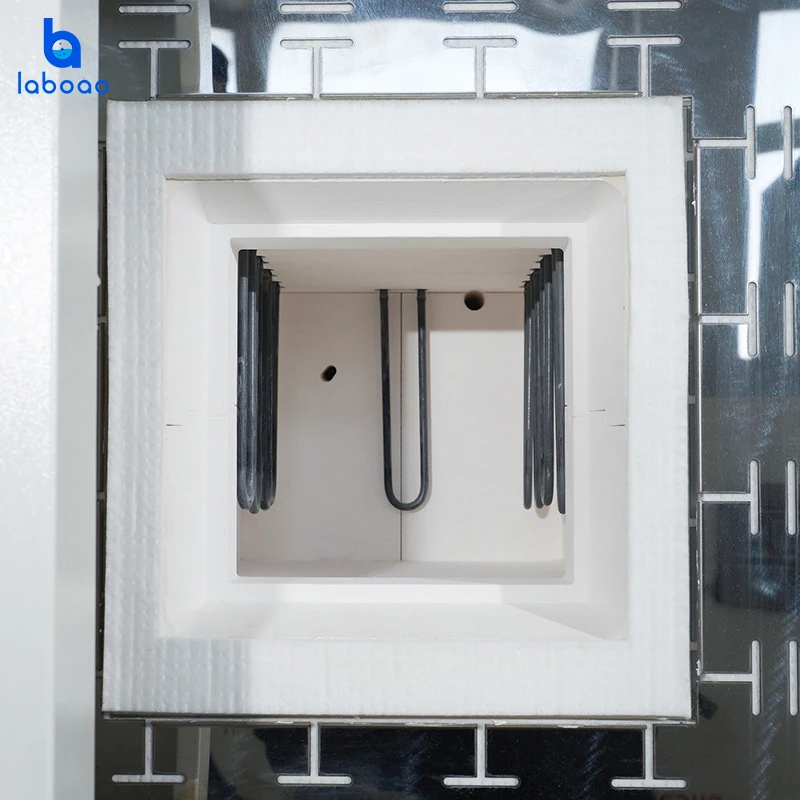

Chamber | polycrystalline mullite fiber | |||||||||

Exhaust vent | Outer diameter: 22 Inside diameter: 18 | |||||||||

Heater | Silicon molybdenum rods | |||||||||

Thermal Insulation | Double forced air diversion | |||||||||

Open Mode | Sliding | |||||||||

Heating Power | 3kw | 6kw | 9kw | 12kw | ||||||

Controller | Controller | D: Single-stage temperature control, digital display P: Imported program temperature control, digital display T: 7-inch color touch screen program temperature control | ||||||||

Control Mode | Microcomputer PID control heating output | |||||||||

Setting Mode | D/P: Slightly touch the five buttons, digital setting mode T: Finger touch settings | |||||||||

Display Mode | D/P: Double row LED digital display T: LCD display | |||||||||

Timer | 0~999.9hours | |||||||||

Operation Function | D: Fixed value operation P/T: Fixed value operation, program operation | |||||||||

Program Mode | D: Single-stage operation P: Program running, 4 curves, total of 40 segments T: Max. 50 segments | |||||||||

Sensor | B-type thermocouple | |||||||||

Auxiliary Function | D/P: Correct functioning, door control functioning T: Correct functioning, door control functioning, real-time curve recording, USB data export | |||||||||

Safety Device | Over current leakage protection switch | |||||||||

Specification | Interior Size(mm) | 150*90*150 | 150*150*150 | 300*150*150 | 300*200*200 | |||||

Exterior Size(mm) | 600*762*1102 | 600*762*1102 | 600*871*1102 | 680*865*1182 | ||||||

Packing Size(mm) | 760*885*1310 | 760*885*1310 | 760*985*1310 | 840*985*1390 | ||||||

Volume | 2L | 4L | 8L | 12L | ||||||

NW/GW(KG) | 70/90 | 80/100 | 110/130 | 150*170 | ||||||

Power Supply | AC220V 50HZ | AC380V 50HZ | ||||||||

Standard Configuration | Equipment*1set, Instruction*1pc, Certificate*1pc | |||||||||

Our Advantages

1. Integrated Design for Efficiency: The furnace features an integrated design, ensuring a lightweight and compact structure for user convenience. This design not only enhances ease of use but also facilitates efficient handling and maneuverability in laboratory settings.

2. Efficient Heat Preservation with Advanced Heating Technology: Utilizes vacuum-formed polycrystalline mullite fiber and special alloy heating wires for optimal heat preservation and uniform temperature distribution. The furnace's cutting-edge heating technology guarantees precise and consistent temperature control, critical for various scientific processes.

3. Enhanced Safety Protocols: Incorporates a protection system with automatic power-off when the door is opened, alongside delayed power resumption for heightened safety during operation. This safety feature ensures a secure operating environment, preventing accidents and safeguarding both users and the equipment.

4. Double-Shell Air Insulation for Temperature Regulation: The double-shell air insulation design maintains a low surface temperature for safety and longevity. This insulation mechanism contributes to user safety, prevents overheating, and extends the lifespan of the furnace, ensuring a reliable and durable performance.

5. User-Friendly Operation with Precision Control: Equipped with dedicated function keys for temperature setting, ensuring a user-friendly interface. The furnace's intuitive controls, combined with advanced features like the auxiliary menu, empower users to manage overheating alarms, perform deviation corrections, apply menu locks, and utilize an overheating prevention device with ease.

2. Efficient Heat Preservation with Advanced Heating Technology: Utilizes vacuum-formed polycrystalline mullite fiber and special alloy heating wires for optimal heat preservation and uniform temperature distribution. The furnace's cutting-edge heating technology guarantees precise and consistent temperature control, critical for various scientific processes.

3. Enhanced Safety Protocols: Incorporates a protection system with automatic power-off when the door is opened, alongside delayed power resumption for heightened safety during operation. This safety feature ensures a secure operating environment, preventing accidents and safeguarding both users and the equipment.

4. Double-Shell Air Insulation for Temperature Regulation: The double-shell air insulation design maintains a low surface temperature for safety and longevity. This insulation mechanism contributes to user safety, prevents overheating, and extends the lifespan of the furnace, ensuring a reliable and durable performance.

5. User-Friendly Operation with Precision Control: Equipped with dedicated function keys for temperature setting, ensuring a user-friendly interface. The furnace's intuitive controls, combined with advanced features like the auxiliary menu, empower users to manage overheating alarms, perform deviation corrections, apply menu locks, and utilize an overheating prevention device with ease.

FAQ

Q1: What distinguishes the Ceramic Fiber Muffle Furnace from other similar products on the market?

A1: The Ceramic Fiber Muffle Furnace stands out due to its integrated design, ensuring a lightweight and compact structure, advanced heating technology with polycrystalline mullite fiber, and safety features like automatic power-off when the door is opened. These factors collectively set it apart in terms of efficiency, safety, and user-friendly operation.

Q2: How does the furnace ensure precise temperature control for various scientific processes?

A2: The furnace employs vacuum-formed polycrystalline mullite fiber and special alloy heating wires, guaranteeing efficient heat preservation and the best temperature uniformity. The combination of a high-precision microcomputer temperature controller and precision sensor ensures accurate and consistent temperature control for diverse applications.

Q3: Can you elaborate on the safety features and their significance in laboratory settings?

A3: Safety is a top priority. The protection system, including automatic power-off when the door is opened and delayed power resumption, enhances user safety. The double-shell air insulation maintains a low surface temperature, preventing accidents and contributing to the longevity of the furnace, crucial in laboratory environments.

Q4: How user-friendly is the operation of the Ceramic Fiber Muffle Furnace?

A4: The furnace is designed with user convenience in mind. Dedicated function keys for temperature setting, an intuitive interface, and an auxiliary menu for advanced operations make it user-friendly. This ensures ease of operation for researchers and scientists with varying levels of expertise.

Q5: What are the key benefits that users can expect from this furnace in terms of efficiency and performance?

A5: Users can expect an efficient and reliable performance due to the furnace's advanced heating technology, precise temperature control, and safety features. The integrated design enhances efficiency, and the user-friendly interface ensures seamless operation, making it an indispensable tool for sintering, melting, and heat treatment processes.

A1: The Ceramic Fiber Muffle Furnace stands out due to its integrated design, ensuring a lightweight and compact structure, advanced heating technology with polycrystalline mullite fiber, and safety features like automatic power-off when the door is opened. These factors collectively set it apart in terms of efficiency, safety, and user-friendly operation.

Q2: How does the furnace ensure precise temperature control for various scientific processes?

A2: The furnace employs vacuum-formed polycrystalline mullite fiber and special alloy heating wires, guaranteeing efficient heat preservation and the best temperature uniformity. The combination of a high-precision microcomputer temperature controller and precision sensor ensures accurate and consistent temperature control for diverse applications.

Q3: Can you elaborate on the safety features and their significance in laboratory settings?

A3: Safety is a top priority. The protection system, including automatic power-off when the door is opened and delayed power resumption, enhances user safety. The double-shell air insulation maintains a low surface temperature, preventing accidents and contributing to the longevity of the furnace, crucial in laboratory environments.

Q4: How user-friendly is the operation of the Ceramic Fiber Muffle Furnace?

A4: The furnace is designed with user convenience in mind. Dedicated function keys for temperature setting, an intuitive interface, and an auxiliary menu for advanced operations make it user-friendly. This ensures ease of operation for researchers and scientists with varying levels of expertise.

Q5: What are the key benefits that users can expect from this furnace in terms of efficiency and performance?

A5: Users can expect an efficient and reliable performance due to the furnace's advanced heating technology, precise temperature control, and safety features. The integrated design enhances efficiency, and the user-friendly interface ensures seamless operation, making it an indispensable tool for sintering, melting, and heat treatment processes.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices