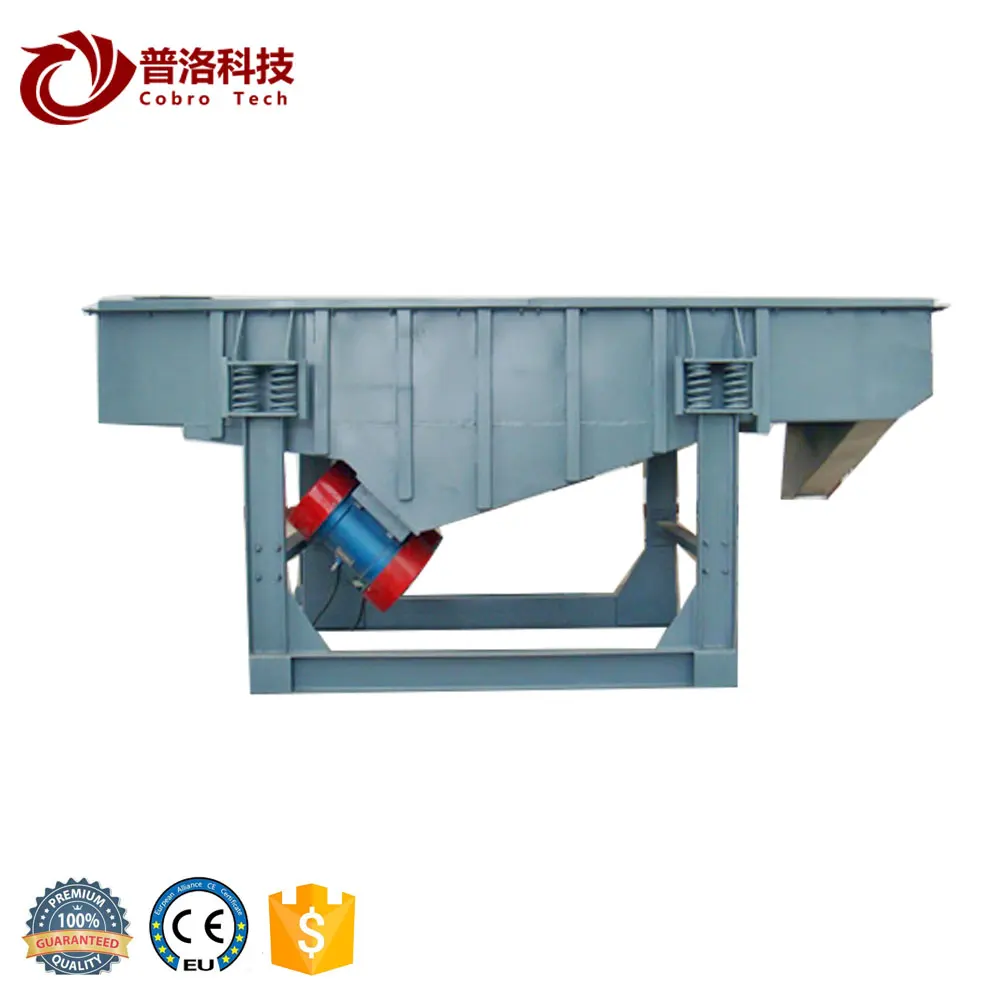

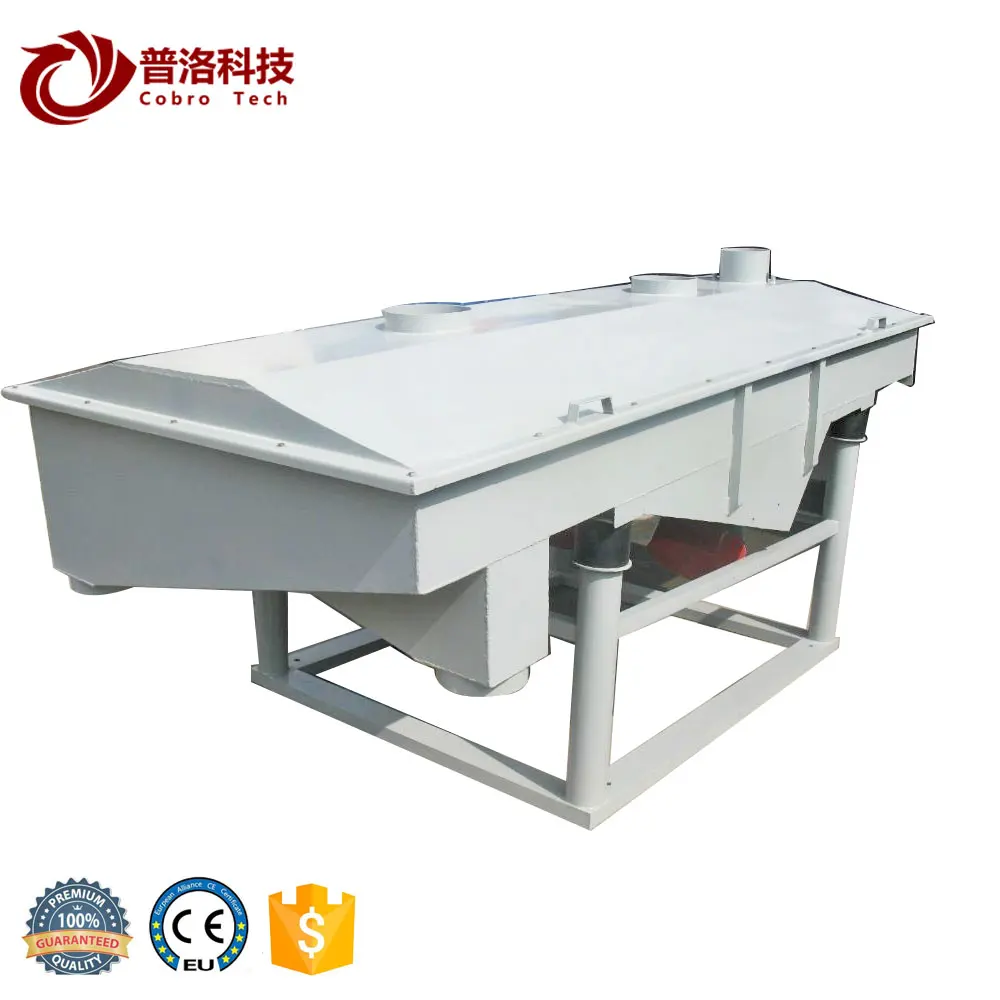

High efficiency sand vibration separator PVC flakes sieve machine beans food powder granule linear vibrating screen

- Category: >>>

- Supplier: COBRO TECH LTD

Share on (1601277771052):

Product Overview

Description

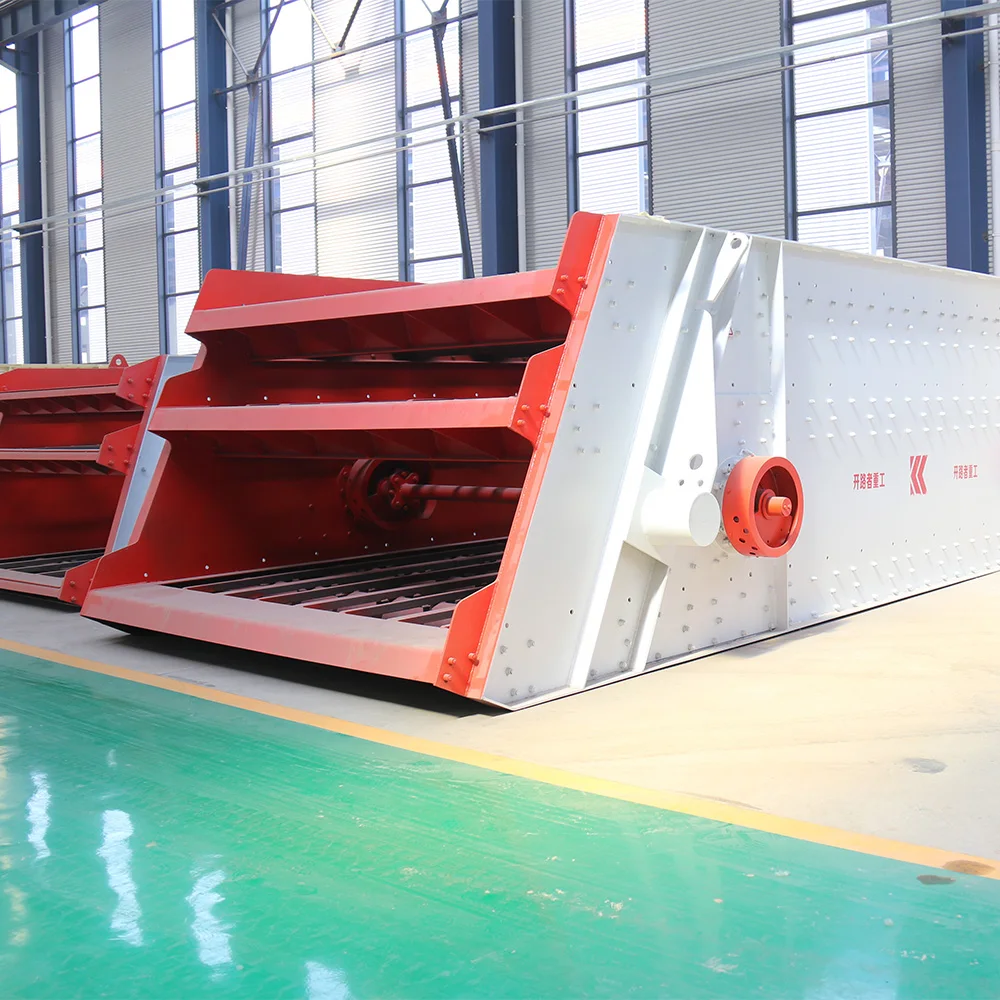

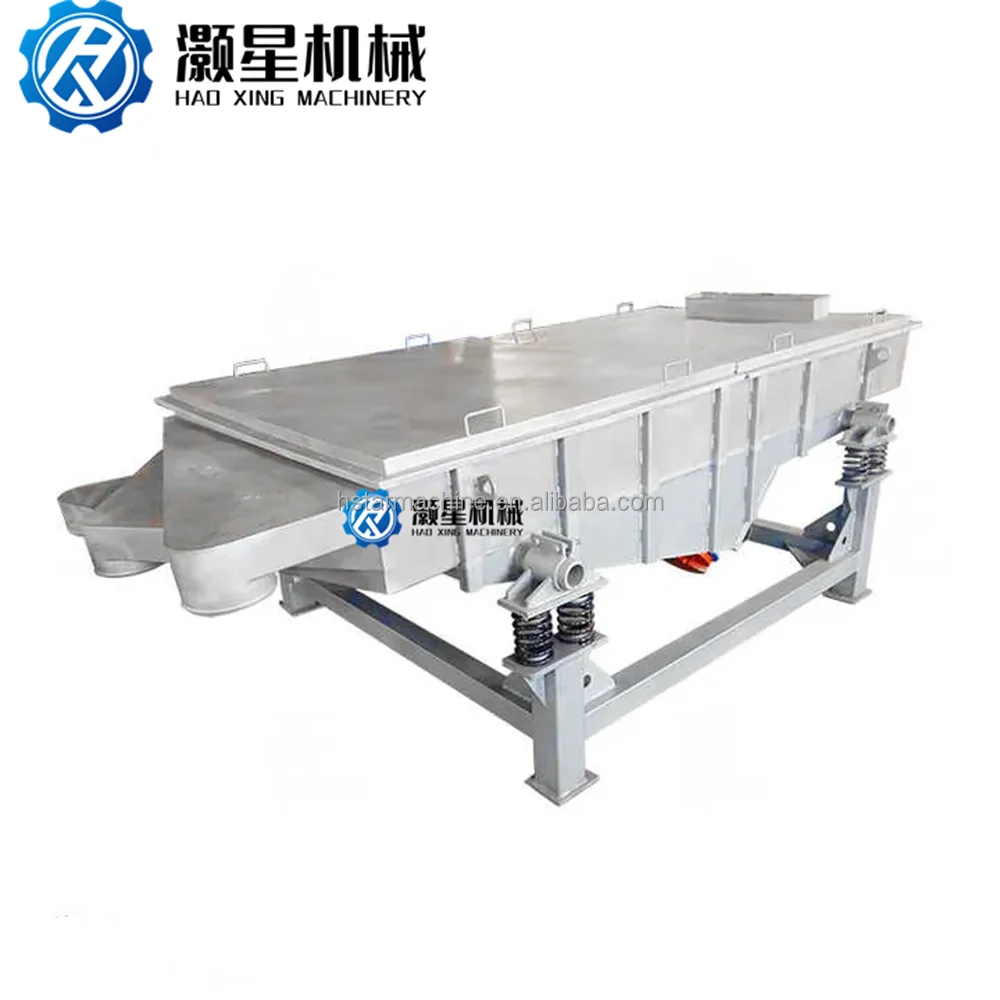

Linear vibrating screen is an efficient screening equipment with features such as low energy consumption, high output, simple structure, easy maintenance, and fully enclosed structure. It can effectively prevent dust overflow and achieve automatic discharge, making it very suitable for assembly line operations. Its vibration acceleration does not exceed 7g, the voltage is 380V, and the electrical control system has thermal overload, overcurrent, and undervoltage protection functions to ensure the safe operation of the equipment. The fixing bolts of the linear sieve mesh are made of stainless steel material, which effectively resists mud corrosion and extends its service life. Its working principle is based on the synchronous reverse rotation of two eccentric blocks of equal mass, generating centrifugal force to achieve material screening. This screening equipment is widely used in various industrial fields, especially in situations where efficient and precise screening is required, demonstrating its unique advantages and value

1.Description

The linear vibrating screen is fully enclosed structure, no dust, auto-nesting, etc., is more suitable for pipeline operations within 24 hours;

The linear vibrating screen has a low energy consumption, high output, simple structure, easy maintenance;

2.Application

Linear vibrating screen has a unique effect on powdery, granular materials selection and classification. Widely used in chemical, pharmaceutical, food, metal, metallurgy, mining and other industries.

Chemical industry: fertilizers, urea, petroleum coke, resins, paints, cosmetics, paints and so on.

The pharmaceutical industry: industrial chemicals, the powder particles pills, pellets, etc;

Food industry: soy, chestnut, small steamed bread, spices, sugar, starch, salt, rice flour, milk powder, soy milk, egg, soy sauce, fruit juice.

Metals, mining metallurgy: aluminum powder, lead powder, copper powder, ore alloy powder, powder electrodes, manganese dioxide, copper powder, magnetic power, abrasives, refractory, kaolin, limestone, alumina, heavy carbon acid calcium, quartz sand.

Other industries: plastics, abrasives, activated carbon, carbon, building materials industry.

3.Parameter

Model | Size(mm) | Feed size(mm) | angle | Amplitude(mm) | Layer | Power |

PLZS-520 | 500*2000 | 0.074-1mm | 0-7 degree | 4-10mm | 1-5mm | 2*0.75kw |

PLZS-525 | 500*2500 | 2*0.75kw | ||||

PLZS-530 | 500*3000 | 2*0.75kw | ||||

PLZS-1020 | 1000*2000 | 2*1.1kw | ||||

PLZS-1025 | 1000*2500 | 2*1.5kw | ||||

PLZS-1030 | 1000*3000 | 2*1.8kw | ||||

PLZS-1040 | 1000*4000 | 2*2.2kw | ||||

PLZS-1225 | 1200*2500 | 2*1.5kw | ||||

PLZS-1235 | 1200*3500 | 2*2.2kw | ||||

PLZS-1540 | 1500*4000 | 2*3.7kw |

We Recommend

Electro Vibrating Feeder Conveyor and Vibrating Screen

Battery Carbon Powder Recycle Ultrasonic Vibrating Sieve Machine

New Arrivals

New products from manufacturers at wholesale prices