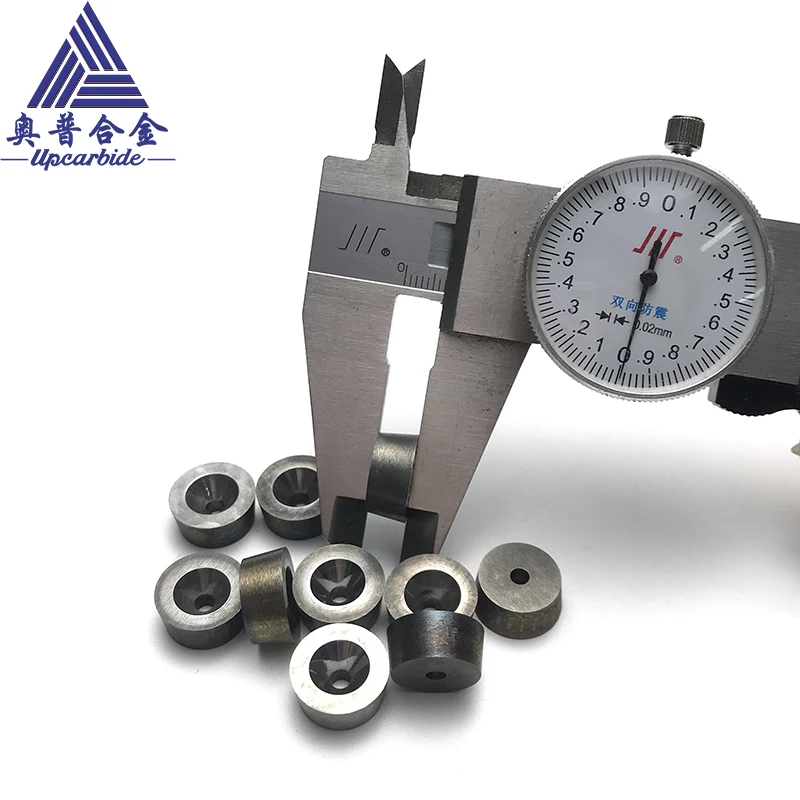

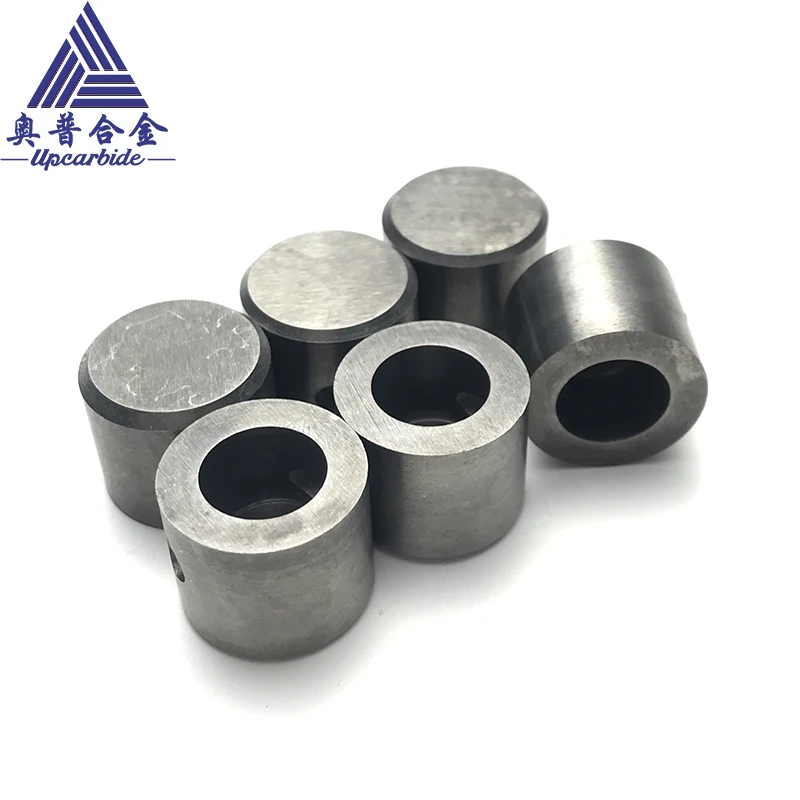

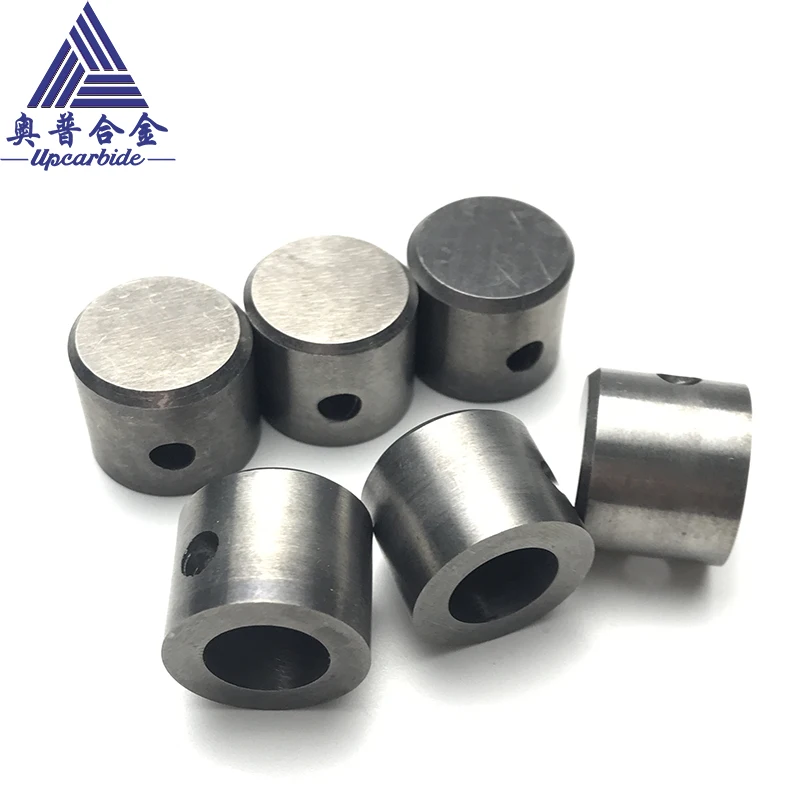

Customize Tungsten Carbide Mould cemented carbide mould

- Category: >>>

- Supplier: Zhuzhou Up Cemented Carbide Co. Ltd.Zhuzhou Ltd.

Share on (1601280419026):

Product Overview

Description

Tungsten carbide ring also known as tungsten steel roll ring, static ring, mechanical seal ring, etc., it is made of refractory metal hard compounds and bonded metal through powder metallurgy process made of an alloy products.Tungsten carbide ring has high hardness, good wear resistance, high finish performance, the use of tungsten carbide ring, can effectively reduce the wear between the punch or bearing and equipment,installed on the shaft to position or protect the shaft, prevent shaft wear, and achieve a guiding

role.

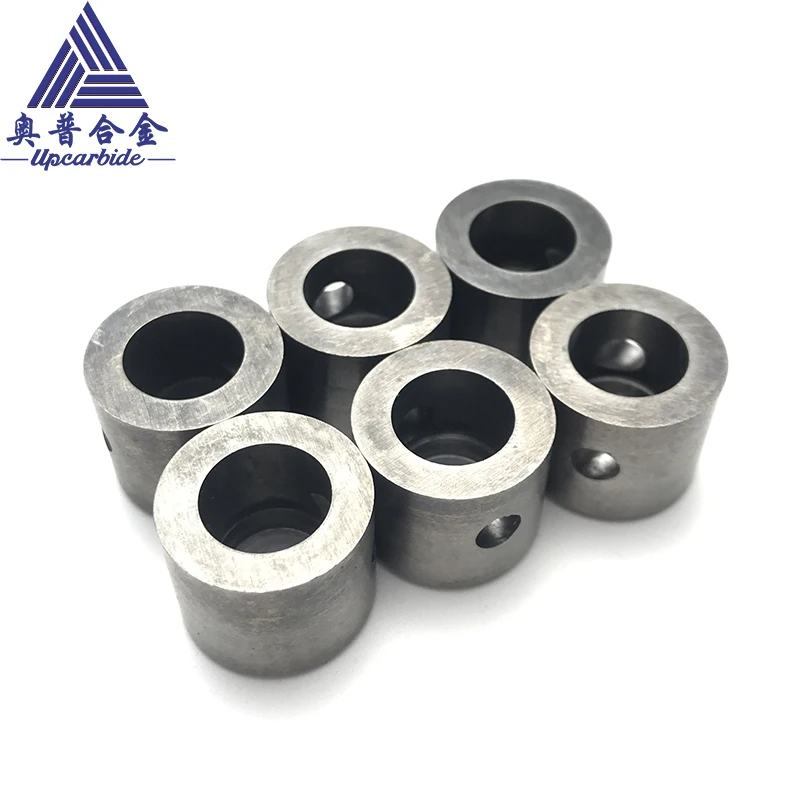

In the stamping die, the carbide ring die is widely used because of its wear-resistant, good finish and does not need to be replaced frequently, so as to achieve the high efficiency of equipment and personnel.

In the drawing mold, mainly used in some copper, stainless steel products of the drawing.

In the stamping die, the carbide ring die is widely used because of its wear-resistant, good finish and does not need to be replaced frequently, so as to achieve the high efficiency of equipment and personnel.

In the drawing mold, mainly used in some copper, stainless steel products of the drawing.

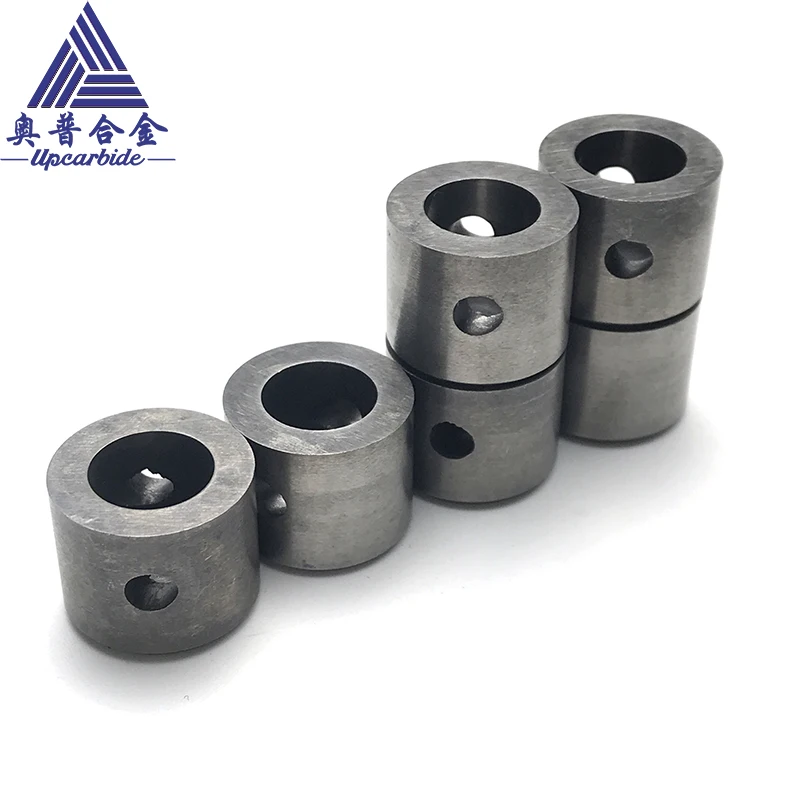

In the application of oil mining machinery, carbide rings have good wear resistance, corrosion resistance and impact resistance and other excellent properties.

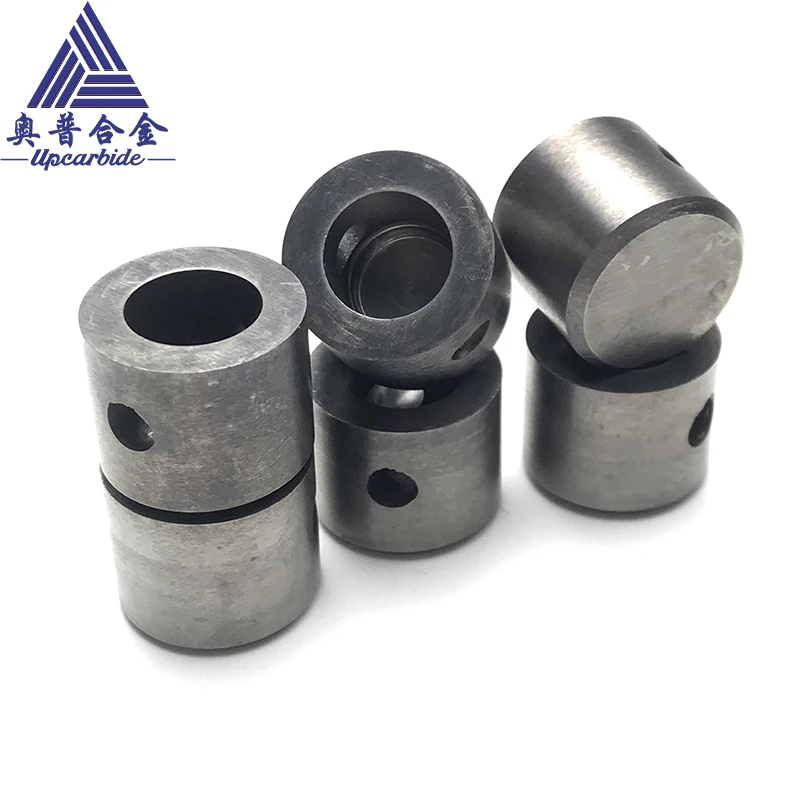

The cemented carbide rings produced by our company have the advantages of strong wear resistance, small friction coefficient, good toughness, long service life, etc., and can be customized according to customer requirements.

Tungsten carbide rings are widely used in the sliding parts of various machinery, such as automatic machinery and equipment(telescopic,swaying, sliding, bending, rotating, rotating parts) hydraulic cylinder guide sleeve, gear pump, textile machinery,plastic forming machine, die casting machine, rubber machinery, food machinery, fitness equipment, office machinery, hydraulic carrier,automobile, motorcycle, agriculture and forestry machinery.

The cemented carbide rings produced by our company have the advantages of strong wear resistance, small friction coefficient, good toughness, long service life, etc., and can be customized according to customer requirements.

Tungsten carbide rings are widely used in the sliding parts of various machinery, such as automatic machinery and equipment(telescopic,swaying, sliding, bending, rotating, rotating parts) hydraulic cylinder guide sleeve, gear pump, textile machinery,plastic forming machine, die casting machine, rubber machinery, food machinery, fitness equipment, office machinery, hydraulic carrier,automobile, motorcycle, agriculture and forestry machinery.

Grade | Density(g/cm3) | Hardness(HRA) | TRS(MPa) | |||

YG6X | 14.9 | 91 | 2500 | |||

YG6 | 14.9 | 90 | 2600 | |||

YG8 | 14.7 | 89 | 2700 | |||

YG11 | 14.4 | 88.5 | 2420 | |||

YG15 | 14.0 | 87.0 | 3000 | |||

YG20 | 13.5 | 85.5 | 2800 | |||

YG16C | 13.9 | 85.0 | 2750 | |||

YG18C | 13.7 | 84.0 | 2800 | |||

YG20C | 13.5 | 83.0 | 2850 | |||

YG22C | 13.3 | 82.0 | 2900 | |||

YG25C | 13.1 | 81.5 | 2950 | |||

Performance&application recommended | ||||||

YG6X | For small stress streteh forming dies or wear resistance parts | |||||

YG6 | For small stress streteh forming dies or wear resistance parts | |||||

YG8 | For normal stress streteh forming dies or wear resistance parts | |||||

YG11 | Forming or stamping dies for metal powders and nonmetal powders. | |||||

YG15 | It is suitable for drawing steel tubes and rods under high compression ratio, manufacturing upsetting,punching and stamping tools under large stress. | |||||

YG20 | It is suitable for manufacturing punching dies for watch parts,leaf spring of musical instruments,battery jars, small sized steel balls,screws,screw caps,etc. | |||||

YG16C | It is suitable for impact-resistant forging dies. | |||||

YG18C | It is suitable for impact-resistant forging dies,hot-forging dies and finishing rollers. | |||||

YG20C | It is suitable for wear resistant or impact resistant dies | |||||

YG22C | It is suitable for nut forming dies and high impact-resistant dies. | |||||

YG25C | It is suitable for stainless screw dies and semifinishing rollers. | |||||

Q1 : Are you manufacturer or trading company ?

We are manufacturer of tungsten carbide products more than 20 years.

Q2: Where is your factory located ?

We are located in Zhuzhou city, Hunan province where is 1 hours-driving from Changsha airport.welcome to visit our factory.

Q3: Are the products High Quality?

Yes. 100% Raw material will be tested before bulk production, and we will check the phys-ical properties, shape and tolerance for ensuring qualified products before shipping.

Q4: What’s your delivery time ?

Generally it is 1-2 days if the goods are in stock; or it is 7-20 days if the goods are not in stock.

Q5: What is products as stock in your warehouse?

Polished ball, unground rod , h6 ground rod ,pure tungsten rod, turning insert ,all kinds tungsten fishing sinker etc.

Q5:Do you provide free samples?

Sure, we can provide free samples. we ready a large number of stock for test samples or trial order.

Q6: How to place an order of tungsten carbide products?

Fill your Order List in our online Inquiry System.Also you can directly contact our salesperson by E-mail / WeChat / Whatsup) 2. within 8 hours feedback when receiving your message.

Q7 : What are certificates together the goods delivery ?

Material report , Certificate of Original , ISO certifiate ,and qualification by third party.

We are manufacturer of tungsten carbide products more than 20 years.

Q2: Where is your factory located ?

We are located in Zhuzhou city, Hunan province where is 1 hours-driving from Changsha airport.welcome to visit our factory.

Q3: Are the products High Quality?

Yes. 100% Raw material will be tested before bulk production, and we will check the phys-ical properties, shape and tolerance for ensuring qualified products before shipping.

Q4: What’s your delivery time ?

Generally it is 1-2 days if the goods are in stock; or it is 7-20 days if the goods are not in stock.

Q5: What is products as stock in your warehouse?

Polished ball, unground rod , h6 ground rod ,pure tungsten rod, turning insert ,all kinds tungsten fishing sinker etc.

Q5:Do you provide free samples?

Sure, we can provide free samples. we ready a large number of stock for test samples or trial order.

Q6: How to place an order of tungsten carbide products?

Fill your Order List in our online Inquiry System.Also you can directly contact our salesperson by E-mail / WeChat / Whatsup) 2. within 8 hours feedback when receiving your message.

Q7 : What are certificates together the goods delivery ?

Material report , Certificate of Original , ISO certifiate ,and qualification by third party.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices