Multi Function Plastic Acrylic Pvc Film Mdf with Sucking Function Heat Press Lamination Machine Vacuum Membrane Press Machine

- Category: >>>

- Supplier: Samet Intelligent Manufacturing Co. Ltd.

Share on (1601281782024):

Product Overview

Description

Products Description

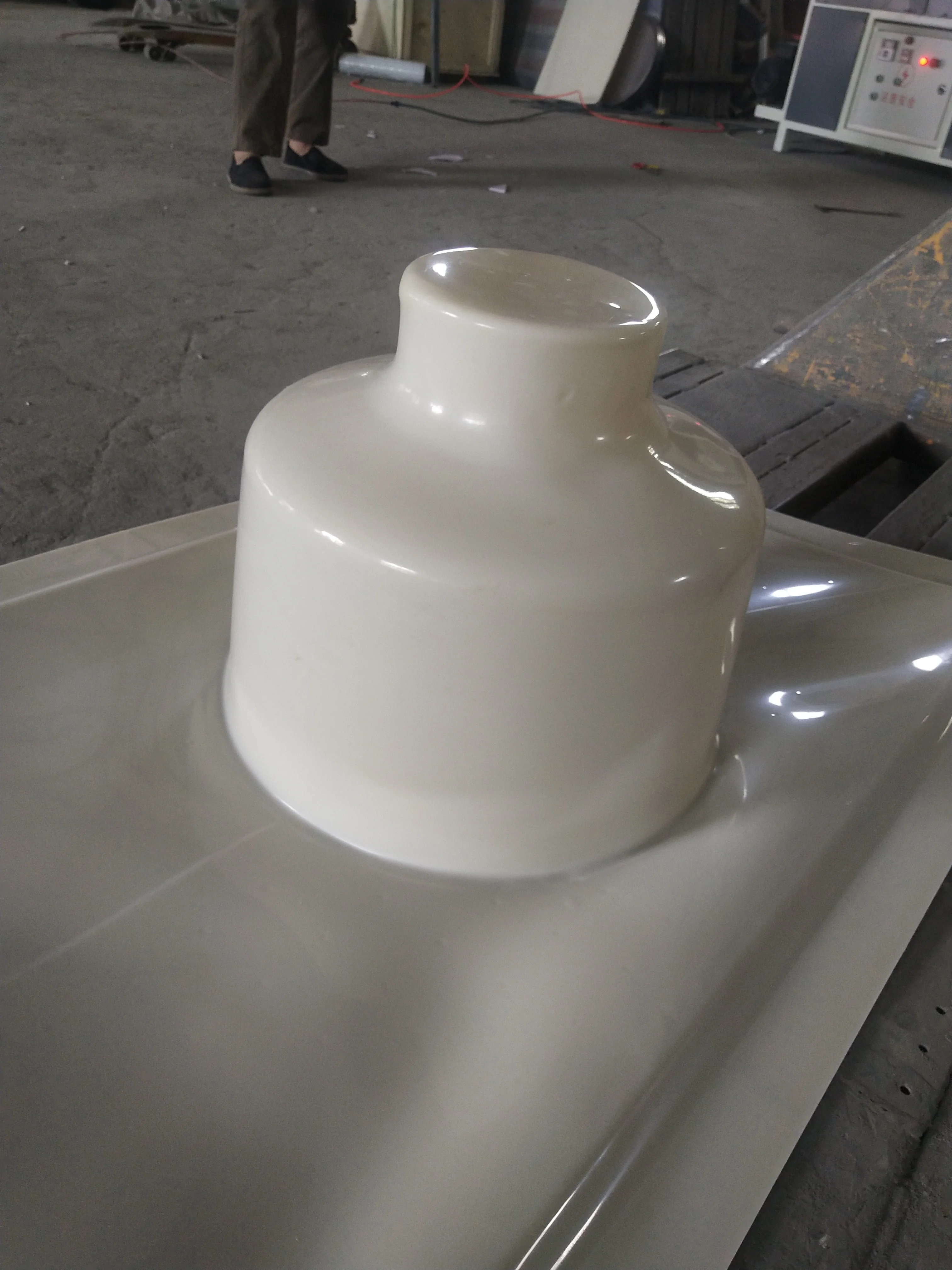

Simple Vacuum Forming Machine Suitable for Advertising Logo Production (also called the thermoforming machine) is a machine that sucks the heat-plasticized PVC, PE, PP, PET, HIPS and other thermoplastic plastic coils into various shapes of advanced packaging boxes, frames and other products. Using the vacuum suction force generated by the vacuum pump, the heated and softened PVC, PET and other thermoplastic plastic sheets are blister-molded into various shapes of vacuum covers, blister trays, blisters, etc...

Machine Parameters

Model | GD-1008 | GD-1310 | GD-1315 | GD-1230 | GD-1325 | ||||

Working table size(mm) | 1000*800 | 1300*1000 | 1300*1500 | 1200*3000 | 1300*2500 | ||||

Forming stroke | 500mm | ||||||||

Power supply | 220V or 380V 3 phase | ||||||||

Max. pressure | 1.5T (Can be adjusted) | ||||||||

Power Consumption | 4KW | 5KW | 6KW | 8KW | 10KW | ||||

Machine size(L×W×H) | 1300*1300*1100mm | 1400*1500*1100mm | 1400*2000*1100mm | 1400*2500*1100mm | 1400*3000*1100mm | ||||

Net weight | 200kg | 300kg | 350kg | 500kg | 700kg | ||||

Details Images

ONE、The materials used in this vacuum forming blister machine are coils, soft pvc, etc...

Thermoplastic sheet PVC PET vacuum

forming plastic tray production machines / thermoforming machine

Simple Vacuum Forming Machine Suitable for Advertising Logo Production

You can customize the molding height you want, and customize the machine that suits you according to the size of your product.

forming plastic tray production machines / thermoforming machine

Simple Vacuum Forming Machine Suitable for Advertising Logo Production

You can customize the molding height you want, and customize the machine that suits you according to the size of your product.

The acrylic blister machine produced by our factory absorbs the best of the industry and is constantly updated; The thermoforming integrated machine (blister machine) produced by adopting balance technology and comprehensive modern advanced guide rail positioning technology has the characteristics of strong power , simple operation, energy saving, and practicality.

1. Using advanced hydraulic transmission technology, a strong hydraulic transmission system is composed of two high-pressure cylinders and hydraulic stations, and is equipped with an advanced, practical and easy-to-master circuit control system to make the floating plate safe and stable; the pressure can reach 12 tons, Compared with screw rod and pneumatic transmission pressure 2-3 times, the service life is longer.

2. Adopt lower radiant heating, energy saving, automatic constant temperature, digital display, heating tube adopts thermal radiant tube, which has energy-saving effect, oven partition heating, from 0 to 400 degrees, it only takes about 10-15 minutes, every 3-5 minutes. When the plate is softened and the temperature rises to the use temperature, electricity consumption is about 15 degrees per hour. The oven has a good heat preservation effect, saves electricity and reduces production costs. The built-in plate of the oven can be moved, which is convenient for replacement and cleaning.

2. Adopt lower radiant heating, energy saving, automatic constant temperature, digital display, heating tube adopts thermal radiant tube, which has energy-saving effect, oven partition heating, from 0 to 400 degrees, it only takes about 10-15 minutes, every 3-5 minutes. When the plate is softened and the temperature rises to the use temperature, electricity consumption is about 15 degrees per hour. The oven has a good heat preservation effect, saves electricity and reduces production costs. The built-in plate of the oven can be moved, which is convenient for replacement and cleaning.

3. The suction system has powerful functions, no need to suction vacuum in stages, and can always be in an ideal negative pressure state, which is more convenient to use.

4. The power supply voltage is 380V and 220V (customized), which is easy to use in the factory and can also be operated in the store..

Automatic Plastic Vacuum Forming Thermo forming Machine for Acrylic ABS PVC Pet Sheet

Automatic Plastic Vacuum Forming Thermo forming Machine for Acrylic ABS PVC Pet Sheet

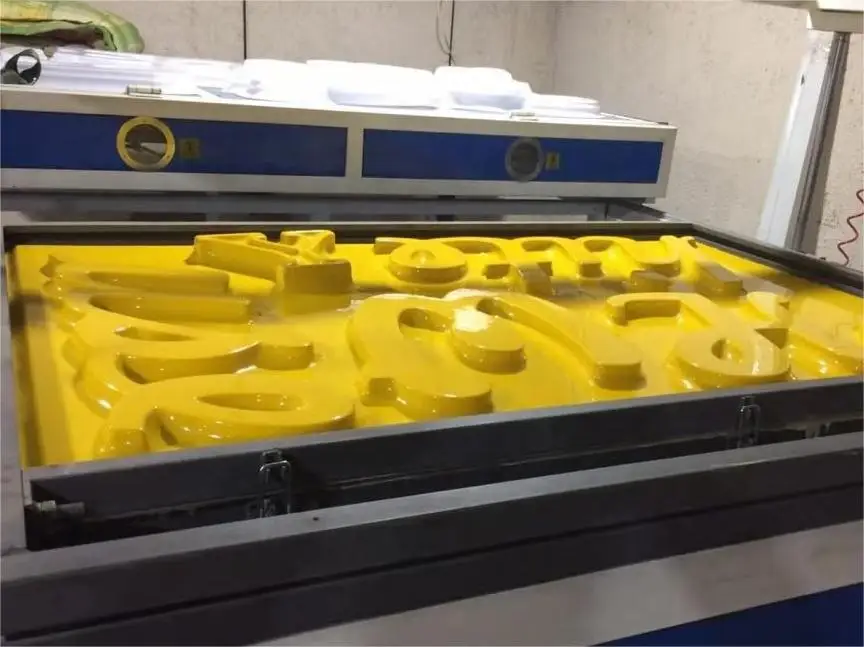

TWO、Plate applicable small vacuum forming machine....

Thermoplastic sheet PVC PET vacuum forming plastic tray production machines /

thermoforming machine

Production range: various concave-convex acrylic characters, pictures, light boxes, signs, etc.

thermoforming machine

Production range: various concave-convex acrylic characters, pictures, light boxes, signs, etc.

Automatic Plastic Vacuum Forming Thermoforming Machine for Acrylic ABS PVC Pet Sheet

‘High Quality-Low Price’ At various prices, there is always one that suits you.

Simple Vacuum Forming Machine Suitable for Advertising Logo Production

‘High Quality-Low Price’ At various prices, there is always one that suits you.

Simple Vacuum Forming Machine Suitable for Advertising Logo Production

Certifications

Product packaging

Payment terms

Company Profile

Samet company is a scientific and technological enterprise specialized in the research, development and manufacture of automatic woodworking equipment and laser CNC equipment.

After nearly 10 years of development experience, the company has a 36000 square modern chemical plant in the beautiful spring city of Jinan, and has become a reliable and reliable CNC machine manufacturer at home and abroad. Our main products include ATC CNC machining center, 4-axis CNC machining center, high-end customized furniture production line, CNC six-sided drill, CNC machining center, CNC side hole machine, edge banding machine, sliding table saw, film coating machine, polishing machine, optical fiber cutting machine, laser engraving machine, stone CNC machining center, vibrating knife cutting machine, plasma cutting machine, 3D scanner and other woodworking machines.

These equipment are used in industry, handicraft and art industries around the world. These include woodworking, metal and stone processing, aluminum manufacturing, mechanical processing, mold manufacturing, etc.

Customers' feedback

FAQ

1. This is the first time I buy the machine, is it easy to operate?

A: We can provide the operation manual or video for guiding.

If it is hard for you learning, we can also help you by "Team viewer" online, with telephone or Skype explain. 2. ARE YOU TRADINGCOMPANY OR MANUFACTURER ?

If it is hard for you learning, we can also help you by "Team viewer" online, with telephone or Skype explain. 2. ARE YOU TRADINGCOMPANY OR MANUFACTURER ?

A: We are factory.

3. Can I visit your factory? A: Yes! We greatly welcome customers to visit our factory!

4. What is your MOQ? A: Our MOQ is 1 set machine. We could send machine to your country port directly, please tell us your port name. There will be best shipping freight and machine price send to you.

We Recommend

Shenzhen disposable plastic punnet thermoforming machine

US $110000-$280000

2022 Chaoxu ABS PC Luggage Suitcase Trolley Bag Making Machine

US $18700-$18900

New Arrivals

New products from manufacturers at wholesale prices