High Speed Dry Cutting Hob Customized M0.1 12 Carbide HSS Gear Hob Cutter For Gear Hobbing Machine

- Category: >>>

- Supplier: Chongqing Fubang Tool Manufacturing Co. Ltd.

Share on (1601282123413):

Product Overview

Description

Product Description

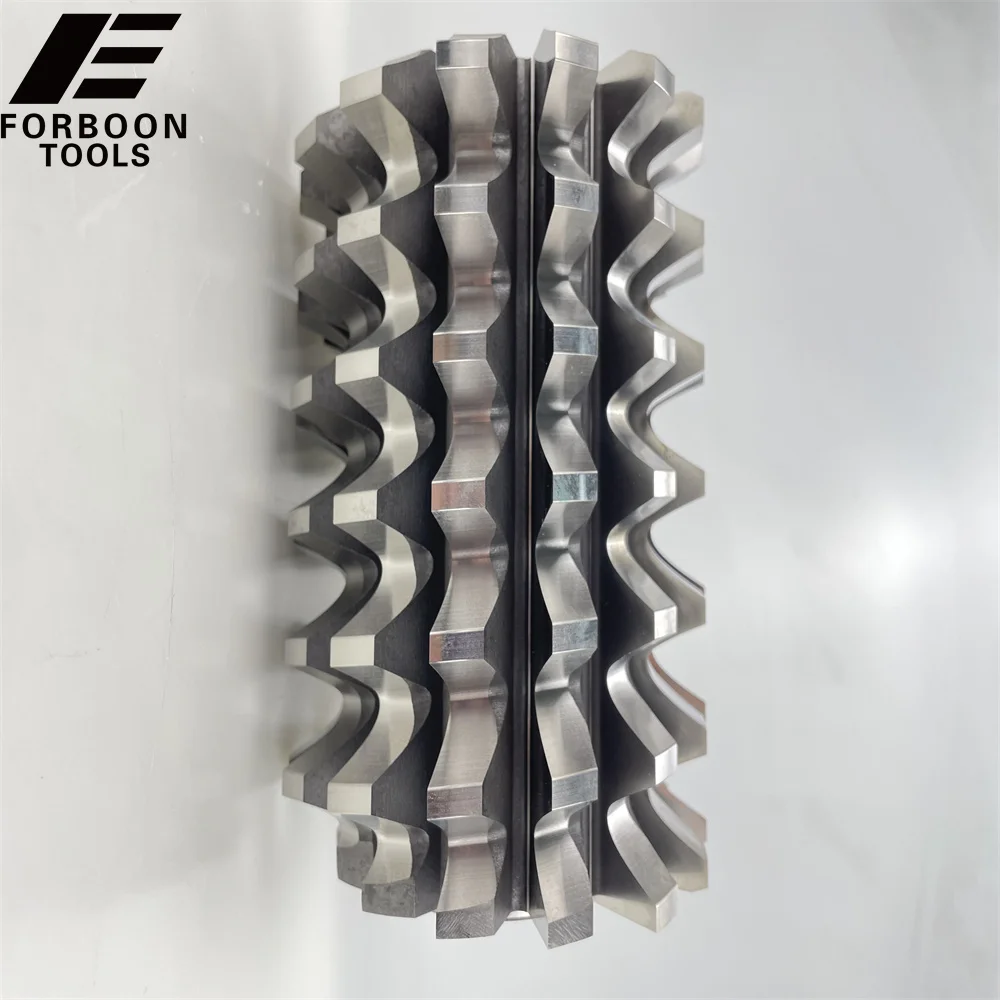

30 degree spline cutter HSS gear parallel side hobs cutter 4 tooth profile

Used for various kinds of high-precision, large volume external gear hobbing, various kinds of shaft involute gear hobbing, high-efficiency, energy-saving, first choice of high-precision, large volume gear processing tool.

All the products are customized according to customers working part drawing, we need know your products drawing first then we make suitable cutters according to the drawing.

The cutters we can make customization for you as below

Specification

Gear cutter type | Type of Structure | ||

Gear Hobbing Cutter | Straight Flute | hob cutter | |

protuberance/pre-shaving hob | |||

Gear Hob Cutter | Straight flute | pre-grinding hob | |

Hob with handle | |||

sprocket hob | |||

spline hob | |||

pulley hob/wheel gear hob cutter | |||

chute/skewed slot | worm gear hob with handle | ||

hob with handle | |||

Application

External gear of automobile gearbox

Spiroid gear pair

Automobile steering gear

Planetary gear and toothed shaft of wind turbine.

Planetary gear

pinion and rack

Various individual sprockets.

Gear shaft of motor shaft

Gear of engineering reducer

Packing & Delivery

Company Profile

Office overview

How can we make high accuracy Gear hob cutters?

The machines we use for high accuracy cutters processing.

The machine is manufactured by Swiss Schlierberg machine Tool Manufacturing Company, which has 115 years of manufacturing history of high-precision tool grinders for various types of gear shaper grinding.The precision dimension stability of this equipment is very excellent in the grinding of cutter profile, and the profile size can meet the DIN AA grade standard.

Teeth precision detection steps

1, system reset, 2, read parameters, 3, replace probe, 4, probe calibration, 5, set the height, 6, start measuring, 7, according to the prompts, 8, complete the measurement to replace the product.

1. System reset; 2. Read parameters; 3. Replace probe; 4. Probe calibration; 5. Set the entry height; 6. Start measurement 7.Complete measurement and replace products.

Contact us

We Recommend

New Arrivals

New products from manufacturers at wholesale prices