New Construction Straddle Container Lifter 50 Ton Rated Loading Capacity 10m Max Lifting Height Motor Bearing Gearbox Core

- Category: >>>

- Supplier: Xinxiang Magicart Cranes Co. Ltd.Xinxiang Ltd.

Share on (1601282179928):

Product Overview

Description

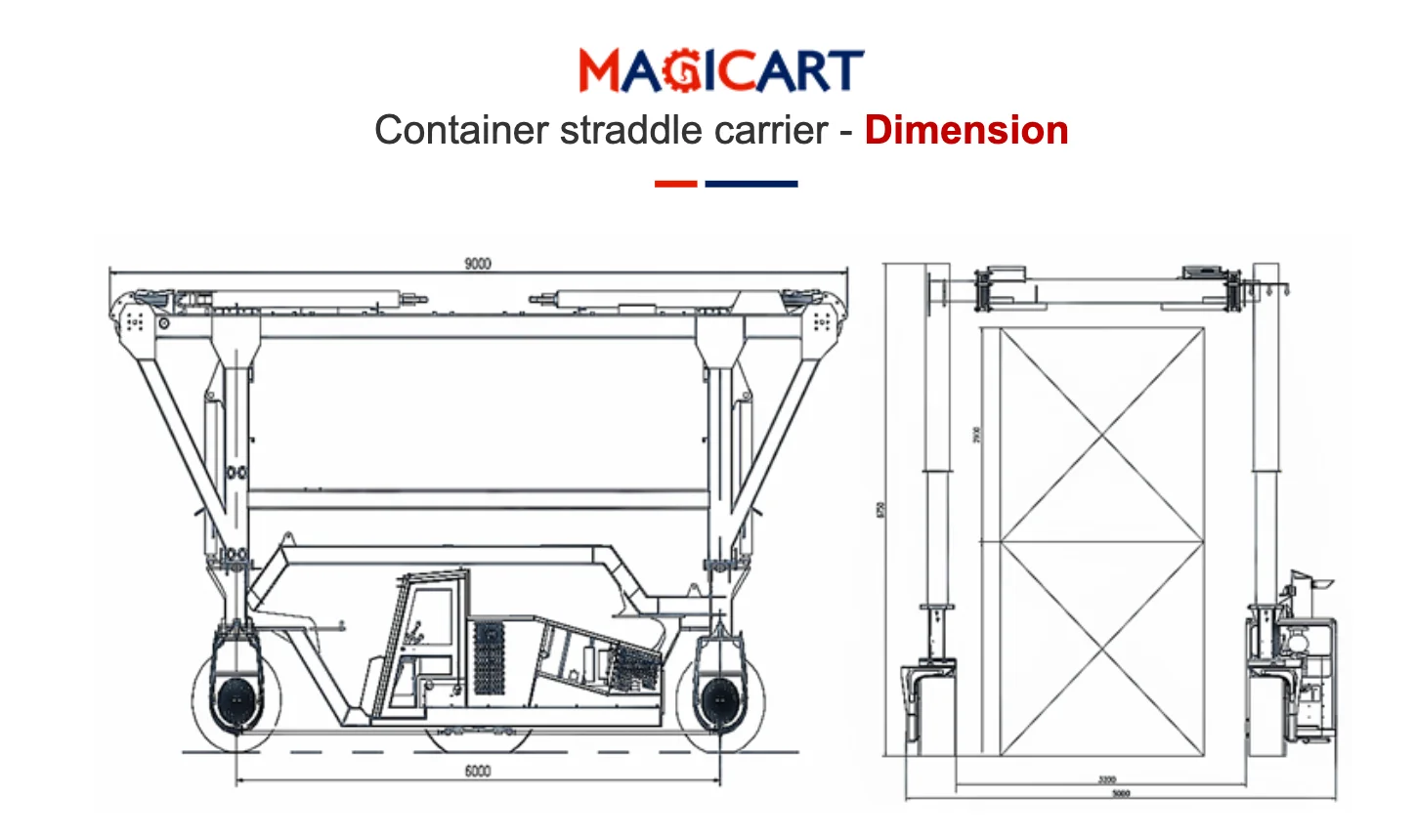

Container Straddle Carrier

MAGICART is a leading professional manufacturer and service provider of crane and material handling equipment, dedicated to the development, design, manufacture, installation and service of crane and material handling technology.

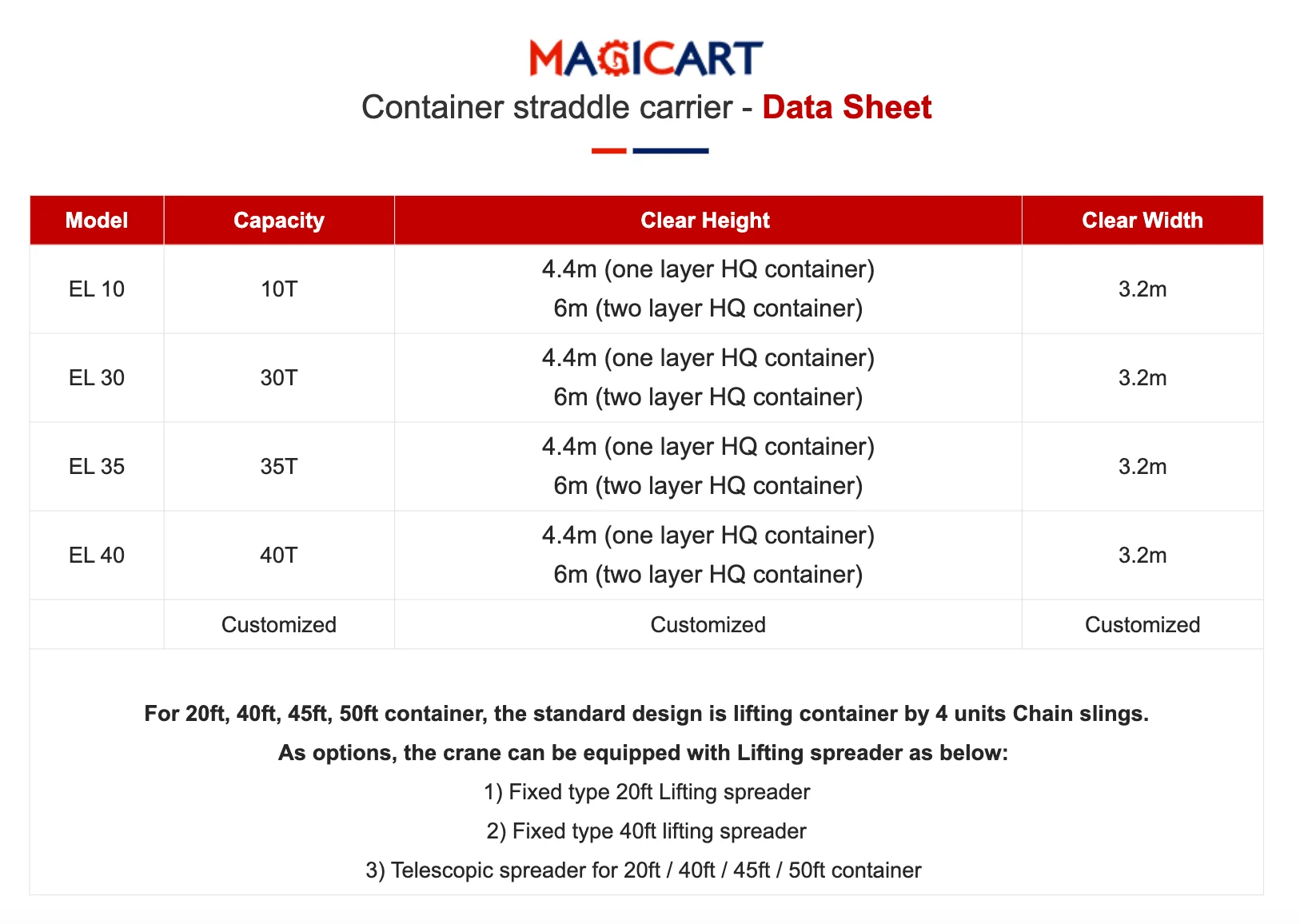

* Suitable for ISO standard 20 foot /40 foot /45 foot containers and similar materials

* Capacity 10t/20t/30t/35t/40t or customized

* PLC control, remote control or cab

* Hydraulic system, powered by diesel engine

* Capacity 10t/20t/30t/35t/40t or customized

* PLC control, remote control or cab

* Hydraulic system, powered by diesel engine

Application field

Container yard, factory, loading and unloading site Special container loading, indoor and outdoor lifting

1. Load Capacity:

* Varied Capacity Options: Customizable load capacities, typically ranging from 30 tons to over 60 tons, to suit different

container sizes and weights.

2. Lift Height:

* Adjustable Lift Heights: Options for varying lift heights to accommodate different stacking configurations in container

yards or warehouses.

3. Span Width:

* Customizable Span Width: Adjustments to the width of the straddle carrier to fit various container sizes and aisle widths in storage areas.

4. Power Options:

* Electric, Diesel, or Hybrid: Choices between electric, diesel, or hybrid power systems to meet operational preferences and environmental considerations.

5. Control Systems:

* User-Friendly Controls: Options for manual, remote, or automated control systems for enhanced safety and convenience during operations.

6. Tire Configuration:

* Solid or Pneumatic Tires: Customization of tire types for specific terrain conditions, including options for solid tires

for durability or pneumatic tires for improved traction.

7. Safety Features:

* Enhanced Safety Options: Additional safety features such as overload protection, anti-collision sensors, cameras for

visibility, and emergency stop buttons.

8. Material and Finish:

* Corrosion-Resistant Materials: Custom finishes and materials designed to withstand harsh marine or industrial

environments, improving longevity and durability.

9. Integrated Technology:

* Smart Technology Features: Options for integrating technology such as GPS tracking, load monitoring systems, and

diagnostics for improved operational efficiency.

10. Environmental Adaptations:

* Design for Harsh Conditions: Customizations to operate effectively in extreme temperatures or weather conditions, ensuring reliability.

11. Ergonomic Design:

* Operator Comfort Features: Customization of operator cabins for enhanced comfort and visibility, including adjustable seats, climate control, and intuitive dashboard layouts.

12. Maintenance Accessibility:

* Easily Accessible Components: Design features that allow for easy access to key components for routine maintenance, reducing downtime.

13. Training and Documentation:

* Operator Training Programs: Custom training resources and documentation to ensure safe and effective use of the container straddle carrier.

* Varied Capacity Options: Customizable load capacities, typically ranging from 30 tons to over 60 tons, to suit different

container sizes and weights.

2. Lift Height:

* Adjustable Lift Heights: Options for varying lift heights to accommodate different stacking configurations in container

yards or warehouses.

3. Span Width:

* Customizable Span Width: Adjustments to the width of the straddle carrier to fit various container sizes and aisle widths in storage areas.

4. Power Options:

* Electric, Diesel, or Hybrid: Choices between electric, diesel, or hybrid power systems to meet operational preferences and environmental considerations.

5. Control Systems:

* User-Friendly Controls: Options for manual, remote, or automated control systems for enhanced safety and convenience during operations.

6. Tire Configuration:

* Solid or Pneumatic Tires: Customization of tire types for specific terrain conditions, including options for solid tires

for durability or pneumatic tires for improved traction.

7. Safety Features:

* Enhanced Safety Options: Additional safety features such as overload protection, anti-collision sensors, cameras for

visibility, and emergency stop buttons.

8. Material and Finish:

* Corrosion-Resistant Materials: Custom finishes and materials designed to withstand harsh marine or industrial

environments, improving longevity and durability.

9. Integrated Technology:

* Smart Technology Features: Options for integrating technology such as GPS tracking, load monitoring systems, and

diagnostics for improved operational efficiency.

10. Environmental Adaptations:

* Design for Harsh Conditions: Customizations to operate effectively in extreme temperatures or weather conditions, ensuring reliability.

11. Ergonomic Design:

* Operator Comfort Features: Customization of operator cabins for enhanced comfort and visibility, including adjustable seats, climate control, and intuitive dashboard layouts.

12. Maintenance Accessibility:

* Easily Accessible Components: Design features that allow for easy access to key components for routine maintenance, reducing downtime.

13. Training and Documentation:

* Operator Training Programs: Custom training resources and documentation to ensure safe and effective use of the container straddle carrier.

A: A container straddle carrier is a type of vehicle designed for lifting, transporting, and stacking shipping containers. It

straddles the container and can move containers in container yards or terminals.

2. Q: What is the typical load capacity of a container straddle carrier?

A: Load capacities typically range from 30 tons to over 60 tons, depending on the specific model and design.

3. Q: How high can a container straddle carrier lift a container?

A: Lift heights can vary by model, but many straddle carriers can lift containers to heights sufficient for stacking up to

several tiers high.

4. Q: What power options are available for container straddle carriers?

A: Straddle carriers can be powered by electric, diesel, or hybrid systems, allowing for flexibility based on operational needs and environmental considerations.

5. Q: What safety features do container straddle carriers have?

A: Common safety features include overload protection, anti-collision sensors, emergency stop buttons, and visibility

enhancements like cameras and lights.

6. Q: How do I choose the right container straddle carrier for my operation?

A: Consider factors such as the types of containers you will be handling, required load capacity, lift height, and site

conditions when selecting a straddle carrier.

7. Q: Is operator training required for using a container straddle carrier?

A: Yes, proper training is essential to ensure operators understand safe operational practices, equipment handling, and

emergency response protocols.

8. Q: What maintenance is required for container straddle carriers?

A: Regular maintenance includes inspecting hydraulic systems, lubricating moving parts, checking tires, and adhering to the manufacturer's maintenance schedule.

9. Q: What are the typical applications for container straddle carriers?

A: Common applications include loading and unloading containers at ports, moving containers within terminals, and stacking containers in storage yards.

10 Q: Are container straddle carriers customizable?

A: Yes, many manufacturers offer customization options, including load capacity, lift height, span width, and additional safety features to meet specific operational needs.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices