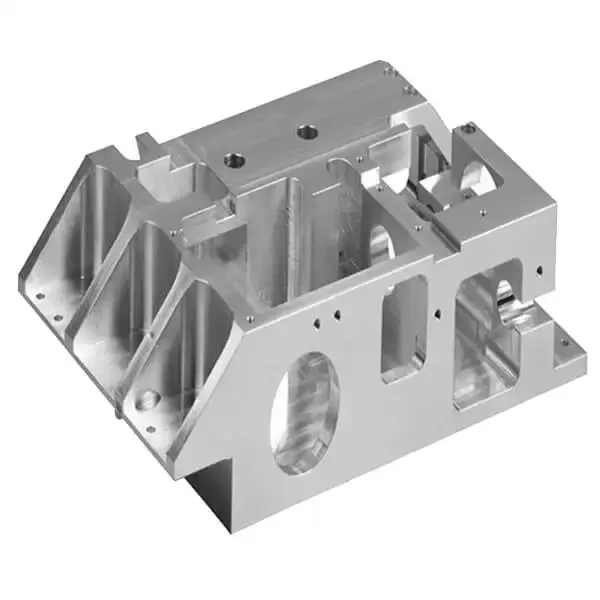

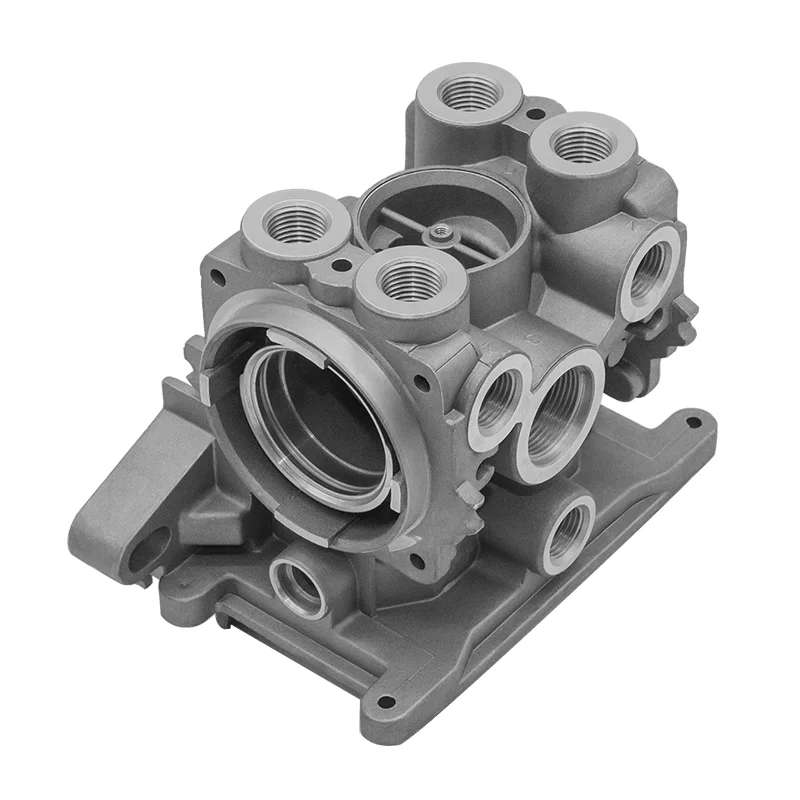

Custom precision automotive engine Aluminum Stainless Steel Metal Titanium Alloy SLM Industrial 5 axis metal 3D printing service

- Category: >>>

- Supplier: Shenzhen Chongxi Precision Metal Products Co. Ltd.Shenzhen Ltd.

Share on (1601282293190):

Product Overview

Description

DIMENSION | TOLERANCE | FLATNESS | TOLERANCE | |||

0~6 | ±0.05 | 0~30 | 0.05 | |||

>6~30 | ±0.1 | >30~100 | 0.1 | |||

>30~120 | ±0.15 | >100~300 | 0.2 | |||

>120~400 | ±0.2 | >300~1000 | 0.3 | |||

>400~1000 | ±0.3 | >1000~3000 | 0.4 | |||

>1000~2000 | ±0.5 | |||||

ANGULAR | VERTICALITY | |||||

(symmetry)0~10 | ±1° | 0~100 | 0.2 | |||

>10~50 | ±30° | >100~300 | 0.3 | |||

>50~120 | ±20° | SYMMETRY | ||||

>120~400 | ±10° | 0.5 | ||||

Technical Requirements | ||||||

1.All parts, including purchased parts and machined parts, must be inspected and passed before they can beassembled | ||||||

2.Parts must be cleaned before assembly, and there must be no burrs, flash, oxidation, skin, rust, chips, oll, colorantsdust, etc | ||||||

3.Carving according to the diagram, clear and durable, refer to the diagram for position and character height | ||||||

4.Except for screws that are not required to be coated with screw glue, all other screws need to be coated with high strength and high-temperature resistant thread glue to prevent loosening | ||||||

5.During the assembly process, parts are not allowed to be knocked, bumped, scratched or rusted | ||||||

6.The brand and model information of standard parts in the drawings are for reference only and must meet the same specifications,size and performance requirements | ||||||

7.The assembly of the movable mechanism must be smooth and flexible, with no jamming or obvious shaking gaps | ||||||

Q1: Where can I get product & price information?

A1: Send us an inquiry e-mail, we will contact you once we received your mail.

Q2: How long will I get the sample?

A2: Depends on your specific items, within 3-7 days generally.

Q3: What kinds of information do you need for a quote?

A3: Kindly please provide the product drawings in PDF, if provide in STEP or IGS will be better.

A1: Send us an inquiry e-mail, we will contact you once we received your mail.

Q2: How long will I get the sample?

A2: Depends on your specific items, within 3-7 days generally.

Q3: What kinds of information do you need for a quote?

A3: Kindly please provide the product drawings in PDF, if provide in STEP or IGS will be better.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices