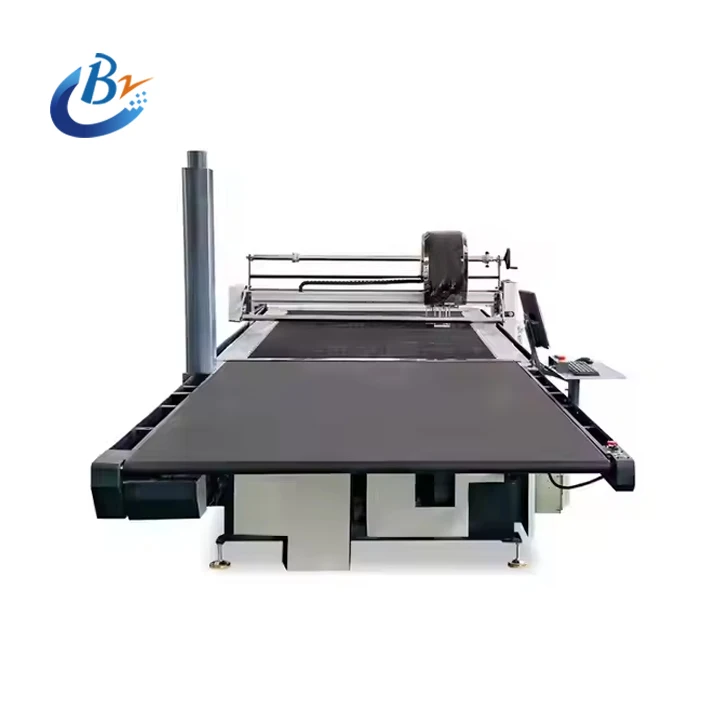

Customized CNC Multi Layer Straight Knife Garment Cutting Machine for All Soft Materials Cloth Cutting

- Category: >>>

- Supplier: Shandong Bangzheng Machinery Equipment Co. Ltd.

Share on (1601283558877):

Product Overview

Description

Product Paramenters

Product Model | BZ-GSD1725 | BZ-GSD2030 | BZ-GSD2330 | BZ-GSD2630 | Customizable Model | ||||

Cutting Range (W*L) | 1.7m*2.5m | 2m*3m | 2.3m*3m | 2.6m*3m | Customizable size | ||||

Production Capacity | 650 pairs of pants per hour, 500 pieces of clothing per hour, 6000 pieces of medical gowns per hour | ||||||||

Cutting length | No limitation with automatic fabric feeding system | ||||||||

Cutting Thickness | 0.1mm——110mm (compressed fabric, after vauum adsorption) | ||||||||

Spreading length | Maximum 50m with spreading table | ||||||||

Maximum Speed | 0-70m/min | ||||||||

Cutting precision | ± 0.1mm | ||||||||

Total Power | 18KW | ||||||||

Power Supply | 220V/380V , 50/60HZ | ||||||||

Cutting style | Straight Knife Continous Up-down Cutting | ||||||||

Knife granding | Automatic spin double-sided sharpening device | ||||||||

Blade cooling | Automatic temperature control air-cooled system and water cooling system | ||||||||

Adsorption method | Frequency conversion vacuum constant pressure control mode | ||||||||

Compressed air | 550KPa , 160L/min | ||||||||

Operating panel | Touch control panel | ||||||||

Operating System | Windows OS | ||||||||

System Features | Supports the overall rotation of the nesting chart, knife-edge conversion, single-piece recutting, one-key deletion of overlapping areas (supports removal of repeated lines), residual cloth cutting | ||||||||

File Format | cut , dxf , plt , iso ,pdf , ggt , gbr,hpgl | ||||||||

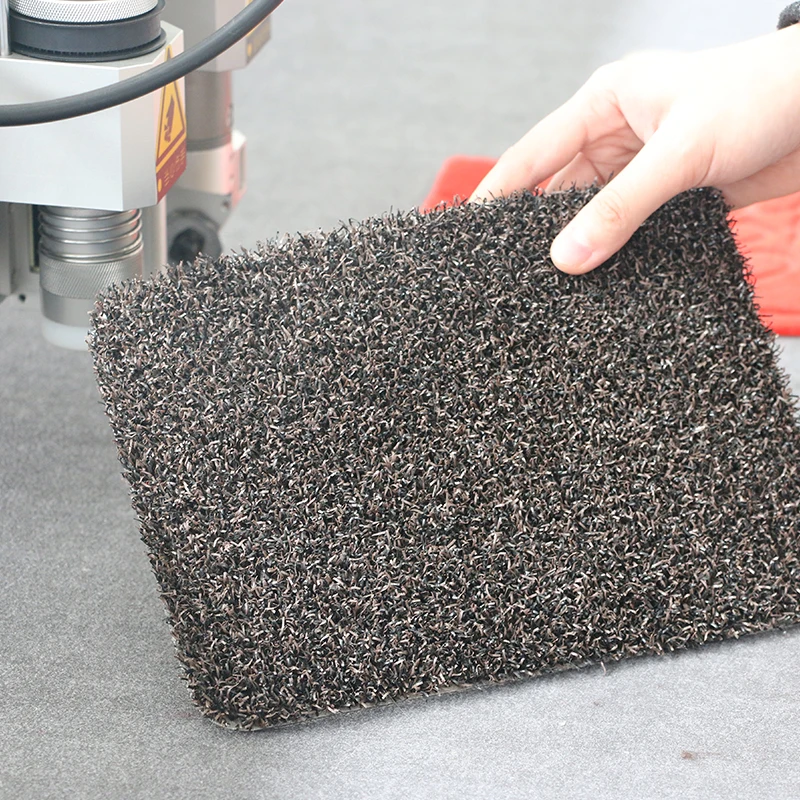

Applied Materials | Fabric,Textiles,Lace,Car interior,Fur,Leather,Denim,Calico,PVC,Foam,Cardboard,Acrylic,Curtain,Carpet,,Gesket,etc. | ||||||||

Standard Fitting Features | 1.Automatic adjustment of cutting speed | 2.Secondary compensation for cuttingvacuum | |||||||

3.Inductive safety protection device | 4.Automatic feeding platform | ||||||||

5.Air flotation workbench * 14 sheets | |||||||||

6.Automatic spreading machine * 1 (single pull, double pull, cutting, automatic edge alignment, etc.) | |||||||||

Other functions | Mobile cutting device, automatic feeding device, pattern scanning, adsorption bed | ||||||||

Main components | 1. Automatic multi-layer cutting bed 2. automatic cloth spreading machine 3. air floatation table | ||||||||

Main Accessories | Motor | Guide Rail | Switch | Knife Drive | Conveyor Belt | ||||

Panasonic | HIWIN | DELIXI | maxon | German | |||||

FULLY AUTOMATIC MULTI-LAYER CUTTING MACHINE

Advantages of multi-layer cutting machine

1.This machine is a cutting flatbed specifically designed for fabrics,fully automatic computer control, one click design and fabric layout, cutting thickness 0.1cm-11cm,suitable for multi-layer cutting.

2. The nesting system adopts computer design, which effectively combines manual and computer automation to improve the nesting efficiency;

3. Computer-controlled automatic cutting,replacing a large number of workers, to achieve mass production;

4. The pieces cut by the equipment have high cutting precision and can be directly sewn, effectively improving the sewing efficiency of lathe workers;

5. The cutting machine control software supports multi-source data formats: it can directly receive common clothing design and typesetting software, etc.;

6. The unique algorithm and motion control technology realize the seamless connection of straight lines and arcs with high cutting precision;

7.The device adopts automatic sharpening technology. The sharpening time can be designed according to the characteristics of the fabric to effectively prolong the service life of the tool;

8. No need to print and save paper plates, high reuse rate, easy to manage plate making;

9. The replacement of consumables is simple and the replacement cost is low;

10. High degree of automation and simple operation.

Product advantages

1.Cutting head

Cuttinghead with automaticsharpening function; when the blade is not sharp, the equip-mentwill automatically grind the blade.

The combined use of corrugated blades and water cooling facilities not only improves cutting quality and efficiency, but also provides an efficient and environmentally friendly solution for cutting various materials by reducing thermal impact and enhancing environmental protection.

The operation controller not only improves production efficiency and cutting accuracy by introducing automation and intelligent technology, but also enhances the reliability and stability of the equipment, while simplifying the operation process and reducing production costs.

4.Equipment silencer

The use of mufflers can help companies reduce the risk of fines and complaints due to noise pollution and maintain a good corporate image. At the same time, a clean working environment can also help improve worker satisfaction, reduce absenteeism and medical expenses due to health problems, and bring significant economic benefits to enterprises.

Simple&Efficient Operation Process

——The BZ2024-cutting software system we developed can design a complex set of clothing templates within 3 seconds with just one click.

——The BZ2024-cutting software system we developed can design a complex set of clothing templates within 3 seconds with just one click.

——Based on thousands of fabric cutting databases, our super algorithm can achieve one click automatic material layout,

provide the optimal cutting path, and achieve a fabric utilization rate of up to 98%.

provide the optimal cutting path, and achieve a fabric utilization rate of up to 98%.

——One click transfer of layout graphics files to the cutting machine for automatic cutting. After cutting, the material is

automatically transported to the receiving table.

——The entire process operation only requires no more than 2 workers.

We provide three types of operation service tutorials:

1. Local on-site installation and training for engineers;

2. 7 * 24-hour remote live streaming guidance for installation and operation;

3. Detailed video operation tutorial.

automatically transported to the receiving table.

——The entire process operation only requires no more than 2 workers.

We provide three types of operation service tutorials:

1. Local on-site installation and training for engineers;

2. 7 * 24-hour remote live streaming guidance for installation and operation;

3. Detailed video operation tutorial.

Applicable Materials

Cutting display

Product Information

High strength integrated frame body, with load-bearing capacity of over 3 tons, does not require splicing or secondary adjustment during installation and use, can be used immediately upon power on.

High speed visual recognition system, capable of achieving various working modes such as tracking cutting, projection without trajectory cutting, etc.

Replaceable bristle bricks with low cost, and the vacuum pump below tightly adsorbs the fabric.

High efficiency max9 KW vacuum pump, capable of continuously variable speed, adjustable adsorption force, and negative pressure in the cutting area up to -22Kpa.

Panasonic servo motor, powerful, cutting machine equipped with 4-5 motors working simultaneously, cutting speed ultra fast, precise control.

China Taiwan's HIWIN stainless steel guide rail is non slip and can achieve μm level positioning accuracy; Load capacity can reach over 1 ton, durable and long-lasting.

All components come from top international brands such as Delixi, Omron, Siemens, Panasonic, etc,stable and durable, and all enjoy quality assurance.

Professional CAD/CAM software, efficient material layout, easy operation, labor-saving, enjoy free upgrades and lifelong training

Multi-layer cutting machine application

Automatic digital fabric cutter is applied in industrial manufacturing for sofa, seat, car seat cover, car floor mat, car carpet, handbag, shoe industry, clothing industry, composite material industry, luggage industry, automobile industry, advertising and printing industry, electronic industry, decoration industry, furniture industry, packaging industry and more.

Company Profile

Bangzheng Machinery Group is located in Jinan City and is the largest physical factory for flexible material cutting in northern China. As a professional manufacturer with many years of industry experience, we have established a good reputation for quality and reliability. Our company is committed to providing excellent cutting solutions for the flexible material industry.

We have a team of skilled experts who are committed to providing cutting-edge technology and unparalleled customer service. The state-of-the-art cutting machines we produce ensure that our customers can handle complex projects with ease. In addition, we invest in continuous employee training and development, allowing us to stay ahead of industry trends and provide the highest level of service to our customers.

If you are looking for a reliable cutting solution provider for your business, Bangzheng Machinery Group is the right choice. We are your partner in success and we stand by our commitment to quality and reliability in all our services. Please contact us today to learn more about our cutting services and how we can help you achieve your business goals.

Corporate Services

1. Pre-sales service - professional personal consultation

A. Free cutting sample production/testing, please send your sample or product CAD file to our chief engineer so that you can intuitively feel our equipment.

A. Free cutting sample production/testing, please send your sample or product CAD file to our chief engineer so that you can intuitively feel our equipment.

B. We are committed to solving all cutting problems of customers and give me professional solutions to support higher manufacturing efficiency and better processing quality.

2. After-sales service - professional qualifications and training Three years of after-sales service includes

A. We provide some parts for free. Buyers need to pay the shipping cost of the parts. Buyers only need to send us pictures of damaged parts.

B. If buyers need our engineers to go to the local area to solve machine problems that they cannot solve by themselves; we will send our engineers for free. Buyers need to pay for the air tickets, accommodation and meals of local engineers.

C. Starting from the purchase of the machine, we will set up an online communication group to facilitate all technical consultations during the cutting process. We can also provide services through email and telephone video.

B. If buyers need our engineers to go to the local area to solve machine problems that they cannot solve by themselves; we will send our engineers for free. Buyers need to pay for the air tickets, accommodation and meals of local engineers.

C. Starting from the purchase of the machine, we will set up an online communication group to facilitate all technical consultations during the cutting process. We can also provide services through email and telephone video.

3. Installation and technical training includes

We send engineers to the customer's factory for local training and installation free of charge. Buyers need to pay for the

engineers' local hotel and catering expenses.

4. All-weather service

Technical support is provided 24 hours a day, never delaying your cutting process.

We send engineers to the customer's factory for local training and installation free of charge. Buyers need to pay for the

engineers' local hotel and catering expenses.

4. All-weather service

Technical support is provided 24 hours a day, never delaying your cutting process.

FAQ

1.——How is the warranty period?

-The machine equipment is guaranteed for 3 years. If you encounter any problems during the use of the equipment, please contact us in time. Bangzheng Group is committed to making progress and development together with customers.

2.——How is the installation and after-sales service of the machine?

-Each of our machines comes with a machine manual and a software manual. The company's backend stores a large number of machine installation and after-sales videos for your reference, and there is 24-hour online technical support. Until your machine can run smoothly.

3.——Does this machine have a test certificate?

-Yes, this machine has passed the European CE, ISO, SGS certification and meets safety standards.

4.——Do you have agents or distributors in our country?

-Yes, first of all, we have users all over the world, and we also want to find more suitable agents in your country. If you are

interested, please feel free to tell us and we will sell it to you at the best price of the agent.

5.——What is the delivery process of the machine?

-After the machine is produced, it is generally transported by sea, but we will plan the most suitable transportation method for you according to your requirements and budget.

In order to recommend you the most favorable and suitable machine, please confirm the following questions:

=======================================

1) What is the maximum width and length of your material? What is the cutting thickness?

2) How many kinds of materials do you want to cut?

3) Do you have any doubts about our company and machines?

4) Please tell us more requirements for cutting or other details

===========================================

After your confirmation, we will recommend you a suitable machine, thanks in advance.

-The machine equipment is guaranteed for 3 years. If you encounter any problems during the use of the equipment, please contact us in time. Bangzheng Group is committed to making progress and development together with customers.

2.——How is the installation and after-sales service of the machine?

-Each of our machines comes with a machine manual and a software manual. The company's backend stores a large number of machine installation and after-sales videos for your reference, and there is 24-hour online technical support. Until your machine can run smoothly.

3.——Does this machine have a test certificate?

-Yes, this machine has passed the European CE, ISO, SGS certification and meets safety standards.

4.——Do you have agents or distributors in our country?

-Yes, first of all, we have users all over the world, and we also want to find more suitable agents in your country. If you are

interested, please feel free to tell us and we will sell it to you at the best price of the agent.

5.——What is the delivery process of the machine?

-After the machine is produced, it is generally transported by sea, but we will plan the most suitable transportation method for you according to your requirements and budget.

In order to recommend you the most favorable and suitable machine, please confirm the following questions:

=======================================

1) What is the maximum width and length of your material? What is the cutting thickness?

2) How many kinds of materials do you want to cut?

3) Do you have any doubts about our company and machines?

4) Please tell us more requirements for cutting or other details

===========================================

After your confirmation, we will recommend you a suitable machine, thanks in advance.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices