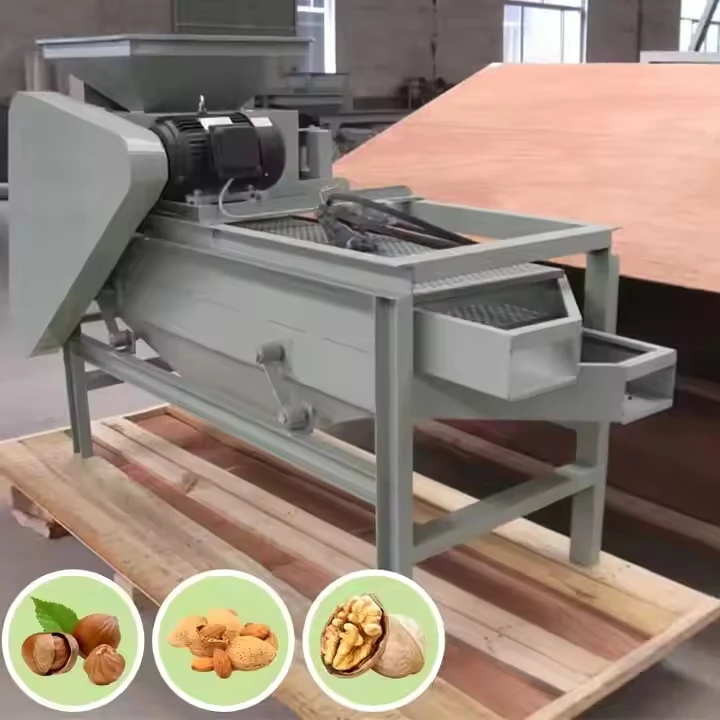

Hot sale Nut Cracker Machine/Hot Selling Separating Almond Hazelnut Sheller Sheller Removing Machine,palm Nut Shelling Machine

- Category: >>>

- Supplier: Luohe Tengli Mechanical And Electrical Equipment Co. Ltd.

Share on (1601284733681):

Product Overview

Description

Commercial almond cracking machine

This machine professional use for broken the hard shell ,like the apricot and filbert to change the distance between

the rollers of this machine ,can broken the different size shell of the products .because the size of the shell is different, so

it is better to broken the big size ,then broken the smaller size .The almond seeds can not be injured after processing.

1.The almond sheller is suitable for cleaning, shelling, sorting almond,also can used for shelling walnut , high efficiency, large output, high degree of automation, production environment clean, is a professional device of choice of almond and walnut plants.

2.Through the hoister feeding,1,2,3 level grade broken,every grade is made up of discharging-sieve and vibrosieve,can strip 3.level grade different specifications of the apricot, walnut hard shell at the same time.

the rollers of this machine ,can broken the different size shell of the products .because the size of the shell is different, so

it is better to broken the big size ,then broken the smaller size .The almond seeds can not be injured after processing.

1.The almond sheller is suitable for cleaning, shelling, sorting almond,also can used for shelling walnut , high efficiency, large output, high degree of automation, production environment clean, is a professional device of choice of almond and walnut plants.

2.Through the hoister feeding,1,2,3 level grade broken,every grade is made up of discharging-sieve and vibrosieve,can strip 3.level grade different specifications of the apricot, walnut hard shell at the same time.

Voltage | 220V/380V |

Capacity | 300-500kg/h |

Power | 2.2kw |

Size | 1900*750*1300mm |

Weight | 280kg |

1.Almond shelling machine :

This machine is mainly used for shelling various hard shell nuts. it can remove the shell of almond, hazelnuts, and other kinds of nuts of different size.It is composed of sheller and hoister. It is automatic feeding with the hoister. Customers can adjust the clearance to get a better breaking performance, based on specific requirement. ,adjusting the processing roller gap after the removal of other specification,and so on.

This machine is mainly used for shelling various hard shell nuts. it can remove the shell of almond, hazelnuts, and other kinds of nuts of different size.It is composed of sheller and hoister. It is automatic feeding with the hoister. Customers can adjust the clearance to get a better breaking performance, based on specific requirement. ,adjusting the processing roller gap after the removal of other specification,and so on.

2.Shell and kernel seperator machine

This machine can separate the shell and kernel totally. the separate rate is 80-90%.

It is useful for Cashew nuts , walnut, hazelnut, palm nuts, Macadamia, etc.

1. The raw fruit enters the screening machine through the elevator to enter the almond sheller for shelling.

2. Shelling machine:The shelling gap is adjusted and matched according to the size of the raw materials to achieve the complete shelling and clean kernels.

3. The shell and kernel separator separates the shell and the kernel, and the kernel is discharged from one material port, and the shell is discharged from the other material port.

4. The storage screening machine screens out the broken shell impurities and feeds the material into the soaking machine quantitatively.

5. The automatic constant temperature system of the soaking machine soaks the nuts, and automatically feeds and discharges the material.

6. The wet peeling machine removes the soaked nut peel.

7. The peeled nuts are manually picked up by air-drying belts and sent to the elevator.

8. The nuts enter the drying and cooling integrated machine from the elevator to dry and cool at low temperature. The finished nuts are at room temperature and the materials are directly packed. According to the output size and the size of the raw materials, it can be customized

Recommend Products

Company Profile

Packing & Delivery

We Recommend

GG-1 Automatic Almond Nut Cracker Almond Dehusking Machine

US $1480-$1500

Electric black walnut skin cracker green walnut peeling machinery price

US $700.00-$880.00

New Arrivals

New products from manufacturers at wholesale prices