Shipyard Jib Crane for Port Fitting Feature Portal Crane Essential for Construction Industries Gear as Core Component

- Category: >>>

- Supplier: Xinxiang Magicart Cranes Co. Ltd.Xinxiang Ltd.

Share on (1601286034844):

Product Overview

Description

Shipyard Crane

MAGICART is a leading professional manufacturer and service provider of crane and material handling equipment, dedicated to the development, design, manufacture, installation and service of crane and material handling technology.

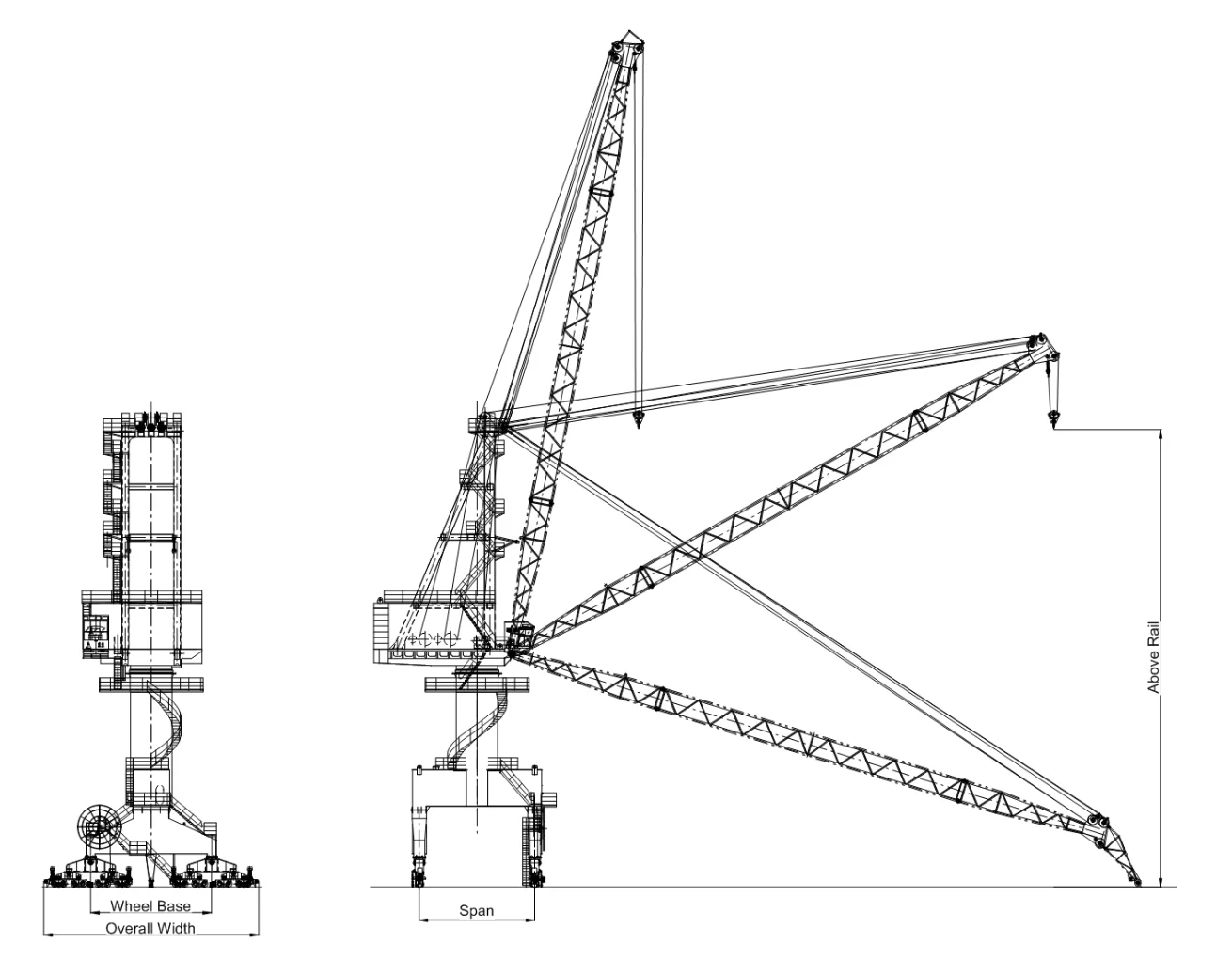

Dry dock, port, material storage yard For ship repair/construction, material handling Run along the track, covering the docks and

docks

docks

Product advantage

Lightweight body, low procurement cost Low power consumption and operating costs Anti-tipping, prevent typhoons

Customization Options for Shipyard Cranes

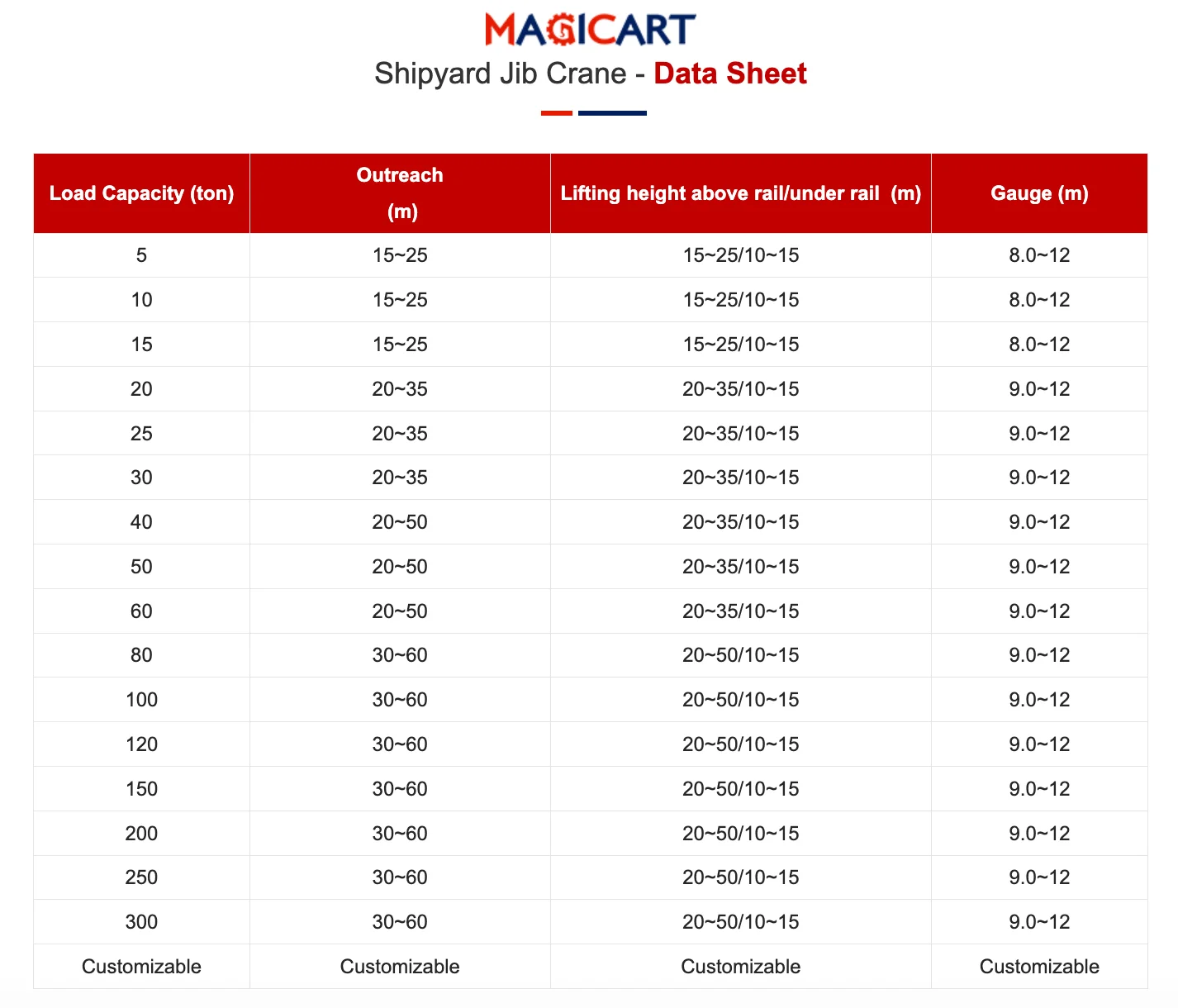

1. Load Capacity:

* Variable Capacity Options: Customizable load capacities from a few tons to over 1,000 tons, depending on the type of

loads, vessels, and specific tasks required.

2. Lift Height:

* Adjustable Lift Height: Customized lift heights for handling various-sized ships and structures, including the capability

to lift loads to significant heights for vessel assembly or repair.

3. Boom Length and Configuration:

* Extended Boom Lengths: Options for longer booms to increase the crane’s reach over the dock or to service multiple areas within the shipyard.

* Fixed, Telescoping, or Articulating Booms: Custom configurations based on specific operational needs, allowing flexibility for shipbuilding, repair, or cargo handling.

4. Power Options:

* Electric, Diesel, or Hybrid Power Systems: Multiple power sources are available depending on the crane’s usage,

environmental requirements, and energy efficiency goals.

5. Rotational Capabilities:

* 360-Degree Rotation: For cranes requiring full rotation to access various positions around the vessel or worksite.

* Partial Rotation: Limited rotation options for applications where only specific angles are necessary.

6. Control Systems:

* Manual, Remote, or Automated Control: Choice of various control systems, including manual operation, remote-controlled options, or automated systems to ensure precision and safety.

* Operator Cab Features: Options for an ergonomic operator cabin with climate control, noise reduction, and panoramic views for improved operator comfort and control.

7. Safety Features:

* Enhanced Safety Systems: Overload protection, anti-sway technology, limit switches, and emergency stop systems.

* Anti-Collision Technology: Advanced sensors and safety protocols to prevent collisions with other cranes, vessels, or

structures in busy shipyard environments.

8. Specialized Attachments:

* Spreader Beams and Hooks: Customizable lifting attachments for handling various types of ship components, heavy cargo, and oversized parts.

* Magnet Lifts or Vacuum Lifters: Specialized attachments for moving sheet metal, steel plates, or other flat materials used in shipbuilding.

9. Load Monitoring Systems:

* Real-Time Load Monitoring: Systems to track and record load weights, movements, and lifting metrics for safety,

compliance, and operational efficiency.

* Smart Diagnostics: Integrated diagnostic tools for monitoring crane performance, identifying maintenance needs, and maximizing uptime.

10. Dock Compatibility:

* Adaptable for Multiple Dock Types: Options for cranes that are compatible with both dry docks and floating docks, allowing for flexible shipyard operations.

* Adjustable Width and Height: Custom sizing to fit different dock dimensions or to operate on narrow dock passages.

11. Emergency Features:

* Emergency Lowering and Braking Systems: Features that ensure safe load descent and crane stability during power failures or emergency shutdowns.

* Evacuation Platforms or Ladders: Safety options for operator evacuation in case of emergency situations.

* Variable Capacity Options: Customizable load capacities from a few tons to over 1,000 tons, depending on the type of

loads, vessels, and specific tasks required.

2. Lift Height:

* Adjustable Lift Height: Customized lift heights for handling various-sized ships and structures, including the capability

to lift loads to significant heights for vessel assembly or repair.

3. Boom Length and Configuration:

* Extended Boom Lengths: Options for longer booms to increase the crane’s reach over the dock or to service multiple areas within the shipyard.

* Fixed, Telescoping, or Articulating Booms: Custom configurations based on specific operational needs, allowing flexibility for shipbuilding, repair, or cargo handling.

4. Power Options:

* Electric, Diesel, or Hybrid Power Systems: Multiple power sources are available depending on the crane’s usage,

environmental requirements, and energy efficiency goals.

5. Rotational Capabilities:

* 360-Degree Rotation: For cranes requiring full rotation to access various positions around the vessel or worksite.

* Partial Rotation: Limited rotation options for applications where only specific angles are necessary.

6. Control Systems:

* Manual, Remote, or Automated Control: Choice of various control systems, including manual operation, remote-controlled options, or automated systems to ensure precision and safety.

* Operator Cab Features: Options for an ergonomic operator cabin with climate control, noise reduction, and panoramic views for improved operator comfort and control.

7. Safety Features:

* Enhanced Safety Systems: Overload protection, anti-sway technology, limit switches, and emergency stop systems.

* Anti-Collision Technology: Advanced sensors and safety protocols to prevent collisions with other cranes, vessels, or

structures in busy shipyard environments.

8. Specialized Attachments:

* Spreader Beams and Hooks: Customizable lifting attachments for handling various types of ship components, heavy cargo, and oversized parts.

* Magnet Lifts or Vacuum Lifters: Specialized attachments for moving sheet metal, steel plates, or other flat materials used in shipbuilding.

9. Load Monitoring Systems:

* Real-Time Load Monitoring: Systems to track and record load weights, movements, and lifting metrics for safety,

compliance, and operational efficiency.

* Smart Diagnostics: Integrated diagnostic tools for monitoring crane performance, identifying maintenance needs, and maximizing uptime.

10. Dock Compatibility:

* Adaptable for Multiple Dock Types: Options for cranes that are compatible with both dry docks and floating docks, allowing for flexible shipyard operations.

* Adjustable Width and Height: Custom sizing to fit different dock dimensions or to operate on narrow dock passages.

11. Emergency Features:

* Emergency Lowering and Braking Systems: Features that ensure safe load descent and crane stability during power failures or emergency shutdowns.

* Evacuation Platforms or Ladders: Safety options for operator evacuation in case of emergency situations.

1. Q: What is a shipyard crane?

A: A shipyard crane is a specialized crane designed for lifting, transporting, and positioning heavy loads such as ship

parts, large cargo, and other materials within a shipyard. They are essential in shipbuilding, vessel maintenance, and

cargo handling operations.

2. Q: What types of shipyard cranes are available?

A: Common types include gantry cranes, floating cranes, jib cranes, and portal cranes. Each type serves specific

functions, such as heavy lifting, moving loads over long distances, or working in confined spaces.

3. Q: Can shipyard cranes be customized?

A: Yes, shipyard cranes can be customized in terms of load capacity, lift height, boom length, mobility, power options,

safety features, and control systems to suit the specific needs of a shipyard.

4. Q: Are shipyard cranes suitable for use in all weather conditions?

A: Shipyard cranes are often designed to withstand various weather conditions, but customizations such as

weather-resistant materials, stability features, and wind-resistant systems can enhance performance in extreme weather.

5. Q: What power options are available for shipyard cranes?

A: Shipyard cranes can be powered by electric motors, diesel engines, or hybrid systems. The choice depends on factors such as energy efficiency, emissions requirements, and operational needs.

6. Q: How do I determine the right shipyard crane for my operation?

A: When selecting a shipyard crane, consider factors like load capacity, lift height, mobility, environmental conditions,

and the types of loads to be handled. Consulting with a crane specialist can help ensure the best fit.

7. Q: How is the stability of shipyard cranes maintained during heavy lifts?

A: Stability is maintained through ballast systems, anti-sway technology, wind-resistance features, and in some cases,

adjustable pontoons or reinforced supports for rail-mounted cranes.

8. Q: What maintenance is required for a shipyard crane?

A: Regular maintenance includes inspecting lifting components, hydraulic systems, cables, and stability systems.

Lubrication, cleaning, and corrosion protection are essential, especially in saltwater environments.

9. Q: What is the expected lifespan of a shipyard crane?

A: With proper maintenance, shipyard cranes can last 20–30 years or more, depending on their usage, environmental

conditions, and maintenance routines.

10. Q: Are shipyard cranes compatible with fleet management systems?

A: Many modern shipyard cranes offer integration with fleet management systems, allowing for real-time tracking,

maintenance scheduling, and operational data analysis.

A: A shipyard crane is a specialized crane designed for lifting, transporting, and positioning heavy loads such as ship

parts, large cargo, and other materials within a shipyard. They are essential in shipbuilding, vessel maintenance, and

cargo handling operations.

2. Q: What types of shipyard cranes are available?

A: Common types include gantry cranes, floating cranes, jib cranes, and portal cranes. Each type serves specific

functions, such as heavy lifting, moving loads over long distances, or working in confined spaces.

3. Q: Can shipyard cranes be customized?

A: Yes, shipyard cranes can be customized in terms of load capacity, lift height, boom length, mobility, power options,

safety features, and control systems to suit the specific needs of a shipyard.

4. Q: Are shipyard cranes suitable for use in all weather conditions?

A: Shipyard cranes are often designed to withstand various weather conditions, but customizations such as

weather-resistant materials, stability features, and wind-resistant systems can enhance performance in extreme weather.

5. Q: What power options are available for shipyard cranes?

A: Shipyard cranes can be powered by electric motors, diesel engines, or hybrid systems. The choice depends on factors such as energy efficiency, emissions requirements, and operational needs.

6. Q: How do I determine the right shipyard crane for my operation?

A: When selecting a shipyard crane, consider factors like load capacity, lift height, mobility, environmental conditions,

and the types of loads to be handled. Consulting with a crane specialist can help ensure the best fit.

7. Q: How is the stability of shipyard cranes maintained during heavy lifts?

A: Stability is maintained through ballast systems, anti-sway technology, wind-resistance features, and in some cases,

adjustable pontoons or reinforced supports for rail-mounted cranes.

8. Q: What maintenance is required for a shipyard crane?

A: Regular maintenance includes inspecting lifting components, hydraulic systems, cables, and stability systems.

Lubrication, cleaning, and corrosion protection are essential, especially in saltwater environments.

9. Q: What is the expected lifespan of a shipyard crane?

A: With proper maintenance, shipyard cranes can last 20–30 years or more, depending on their usage, environmental

conditions, and maintenance routines.

10. Q: Are shipyard cranes compatible with fleet management systems?

A: Many modern shipyard cranes offer integration with fleet management systems, allowing for real-time tracking,

maintenance scheduling, and operational data analysis.

We Recommend

Port Jib Portal Slewing Mobile Harbour Crane for Mobile Portal Crane 25t 45m Boom

$140,000.00-150,000.00

40 ton Harbour Ship Pedestal Crane 10 ton 30 ton fixed harbour portal dock crane for sale

$180,000.00-200,000.00

Hot sale 20 ton electric mobile shipyard crane jib harbour portal crane

$190,000.00-200,000.00

New Arrivals

New products from manufacturers at wholesale prices