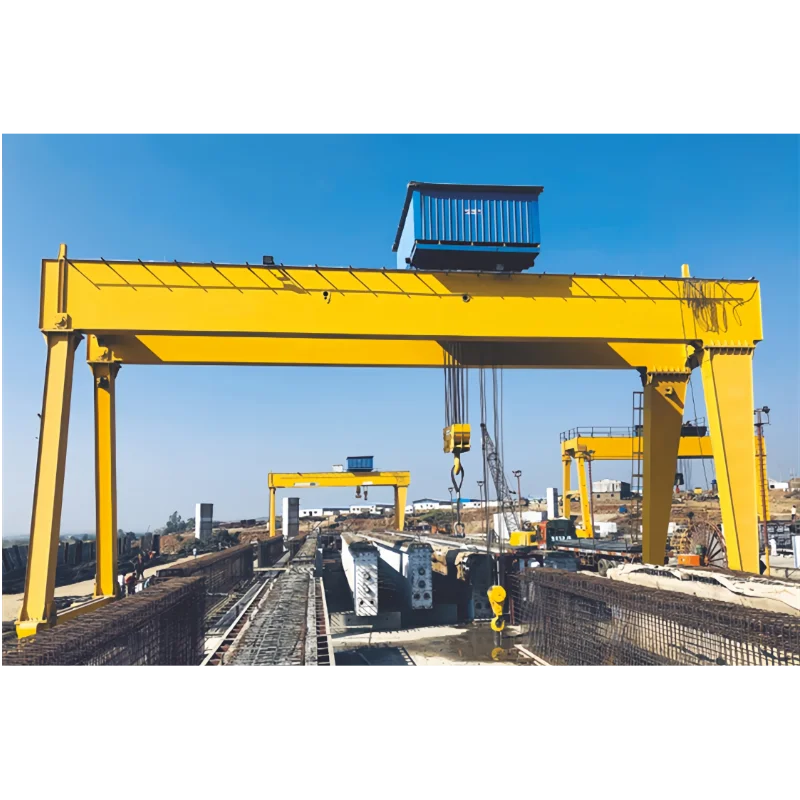

Heavy Duty Rail Mounted Gantry Crane with Electric Power Source 50 Ton Loading Capacity for Construction Industries Outdoors

- Category: >>>

- Supplier: Xinxiang Magicart Cranes Co. Ltd.Xinxiang Ltd.

Share on (1601286838049):

Product Overview

Description

Rail Mounted Gantry (RMG) Crane

A Rail Mounted Gantry (RMG) Crane is a high-capacity, rail-guided gantry crane designed for moving, stacking, and handling large cargo efficiently and precisely in various industrial applications. RMG cranes play a crucial role in high-density storage environments where maximizing space and increasing productivity are essential. Unlike rubber-tyred gantry (RTG) cranes, RMG cranes move on fixed rails, making them especially suited for environments that require long-term, high-precision cargo handling along designated paths.

* Efficient Container Handling: RMG cranes are optimized for quick loading, unloading, and stacking, reducing turnaround times in container and intermodal yards.

* High Load Capacity: Built for strength, RMG cranes can lift heavy cargo loads, often handling 20 tons to over 100 tons based on customization and application requirements.

* Enhanced Space Utilization: Ideal for high-density stacking, they allow optimal use of space, crucial for container terminals and storage facilities.

* Environmental Efficiency: Powered by electricity, RMG cranes provide energy-efficient operation with reduced emissions, making them suitable for eco-sensitive environments.

* Cost-Efficiency: Due to their low operating and maintenance costs, RMG cranes are a cost-effective solution for high-volume operations.

* High Load Capacity: Built for strength, RMG cranes can lift heavy cargo loads, often handling 20 tons to over 100 tons based on customization and application requirements.

* Enhanced Space Utilization: Ideal for high-density stacking, they allow optimal use of space, crucial for container terminals and storage facilities.

* Environmental Efficiency: Powered by electricity, RMG cranes provide energy-efficient operation with reduced emissions, making them suitable for eco-sensitive environments.

* Cost-Efficiency: Due to their low operating and maintenance costs, RMG cranes are a cost-effective solution for high-volume operations.

Data Sheet

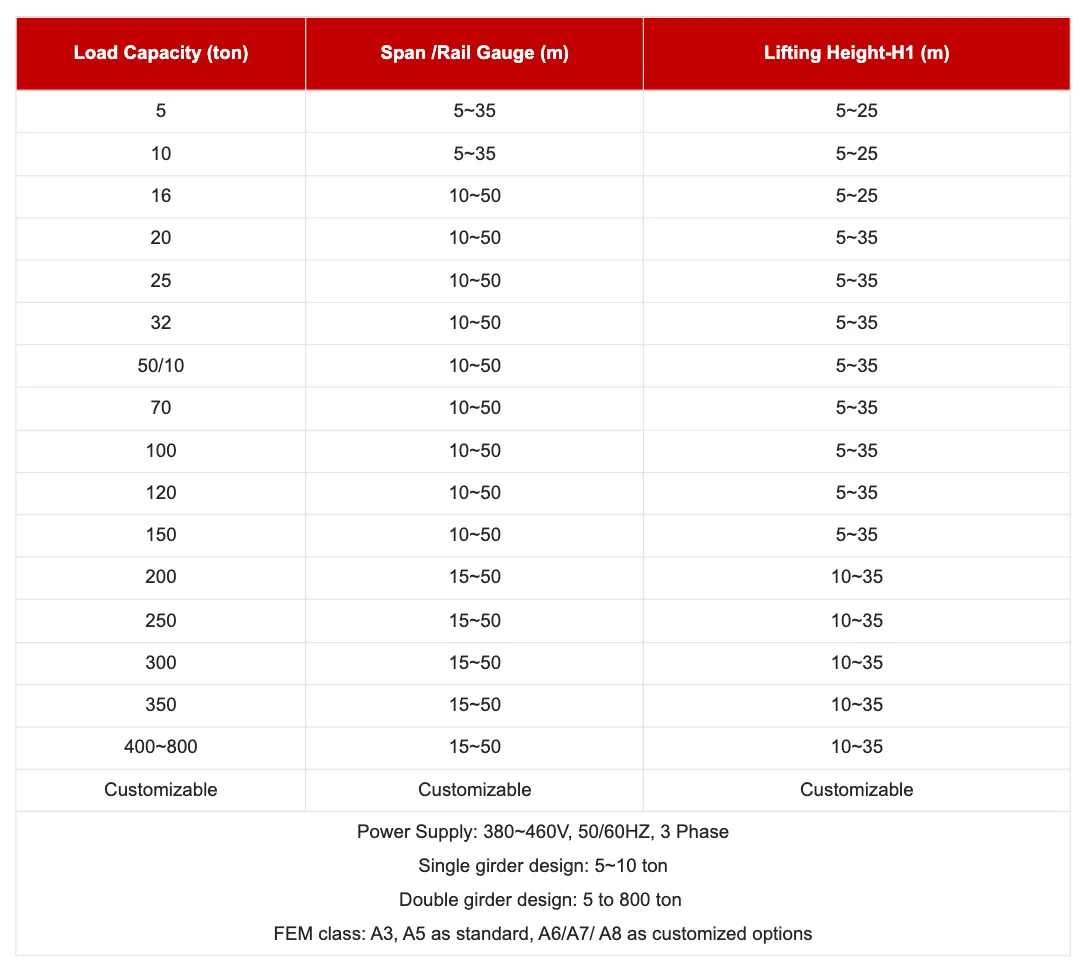

1. Load Capacity:

* Customizable Load Capacities: Options to handle a range of loads, typically from 20 tons to over 100 tons, depending on specific applications like container handling, bulk cargo, or steel yard operations.

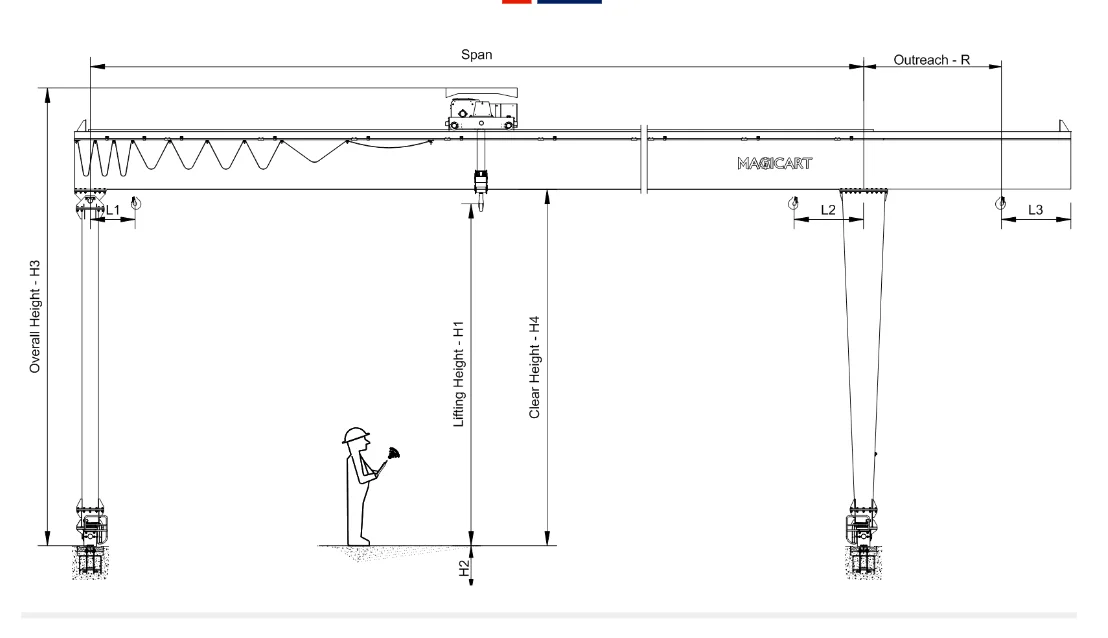

2. Span and Clearance:

* Adjustable Span Width: Custom span width based on the width of container rows, rail tracks, or stacking requirements.

* Height Clearance: Tailored height clearance to allow lifting over various container stacks, railcars, or other structures.

3. Lifting Height and Reach:

* Variable Lifting Heights: Customizable lifting height options, particularly useful in high-density stacking environments

or for stacking multi-tier containers.

* Extended Reach Options: Adjustments to reach beyond standard stacking rows or to span multiple lanes of rail or vehicle traffic.

4. Power Source Options:

* Electric-Powered: Standard electric power supply for quiet, emission-free operation, ideal for urban or eco-sensitive

environments.

* Diesel-Electric Hybrid Systems: Hybrid power options that allow flexibility in areas with limited electrical

infrastructure, reducing fuel costs and emissions.

5. Control Systems:

* Remote, Manual, or Automated Control: Customizable control options, including remote controls, manual operation, or fully automated systems to streamline operations.

* Advanced Operator Cab: Ergonomically designed operator cabins with climate control, enhanced visibility, and noise

insulation for improved operator comfort and safety.

6. Anti-Sway and Load Control:

* Anti-Sway Technology: Customization for anti-sway systems that improve load stability, crucial for high-precision

applications and handling heavy or sensitive cargo.

* Dynamic Load Control: Enhanced load control systems to optimize lifting speed, reduce sway, and ensure safe, steady movements.

7. Stacking and Spreader Options:

* Customizable Spreaders: Options for adjustable spreaders to handle different container sizes, bulk loads, or specialized cargo.

* Automatic Stacking Function: Stacking functionality for efficient container stacking, improving space usage in port or

yard applications.

8. Safety Systems:

* Overload Protection: Customizable overload protection systems to prevent lifting beyond the crane’s rated capacity.

* Collision Prevention: Anti-collision systems with sensors and automatic braking to prevent accidents, especially in

high-traffic areas.

* Emergency Stop and Recovery Features: Advanced emergency stop functions, recovery procedures, and load descent options for quick, safe responses during critical situations.

9. Customized Wheel and Rail Options:

* Rail Clamps and Braking Systems: Customizable rail clamps, anti-skid brakes, and stabilizers to secure the crane in place during heavy winds or loading operations.

* Heavy-Duty Wheels: High-durability wheels designed to withstand continuous operation on rough or irregular rail surfaces.

10. Eco-Friendly Options:

* Regenerative Braking: Energy-saving options such as regenerative braking, which converts excess energy into usable power.

* Reduced Emission Systems: Low-emission or emission-free operation, depending on regional regulations and environmental impact goals.

11. Auxiliary Attachments:

* Magnetic or Vacuum Lifters: Specialized attachments for handling steel plates, sheet metal, or other non-containerized loads.

* Custom Lifting Attachments: Options for custom hooks, spreader bars, or lifting slings to handle a variety of load types, from containers to oversized cargo.

* Customizable Load Capacities: Options to handle a range of loads, typically from 20 tons to over 100 tons, depending on specific applications like container handling, bulk cargo, or steel yard operations.

2. Span and Clearance:

* Adjustable Span Width: Custom span width based on the width of container rows, rail tracks, or stacking requirements.

* Height Clearance: Tailored height clearance to allow lifting over various container stacks, railcars, or other structures.

3. Lifting Height and Reach:

* Variable Lifting Heights: Customizable lifting height options, particularly useful in high-density stacking environments

or for stacking multi-tier containers.

* Extended Reach Options: Adjustments to reach beyond standard stacking rows or to span multiple lanes of rail or vehicle traffic.

4. Power Source Options:

* Electric-Powered: Standard electric power supply for quiet, emission-free operation, ideal for urban or eco-sensitive

environments.

* Diesel-Electric Hybrid Systems: Hybrid power options that allow flexibility in areas with limited electrical

infrastructure, reducing fuel costs and emissions.

5. Control Systems:

* Remote, Manual, or Automated Control: Customizable control options, including remote controls, manual operation, or fully automated systems to streamline operations.

* Advanced Operator Cab: Ergonomically designed operator cabins with climate control, enhanced visibility, and noise

insulation for improved operator comfort and safety.

6. Anti-Sway and Load Control:

* Anti-Sway Technology: Customization for anti-sway systems that improve load stability, crucial for high-precision

applications and handling heavy or sensitive cargo.

* Dynamic Load Control: Enhanced load control systems to optimize lifting speed, reduce sway, and ensure safe, steady movements.

7. Stacking and Spreader Options:

* Customizable Spreaders: Options for adjustable spreaders to handle different container sizes, bulk loads, or specialized cargo.

* Automatic Stacking Function: Stacking functionality for efficient container stacking, improving space usage in port or

yard applications.

8. Safety Systems:

* Overload Protection: Customizable overload protection systems to prevent lifting beyond the crane’s rated capacity.

* Collision Prevention: Anti-collision systems with sensors and automatic braking to prevent accidents, especially in

high-traffic areas.

* Emergency Stop and Recovery Features: Advanced emergency stop functions, recovery procedures, and load descent options for quick, safe responses during critical situations.

9. Customized Wheel and Rail Options:

* Rail Clamps and Braking Systems: Customizable rail clamps, anti-skid brakes, and stabilizers to secure the crane in place during heavy winds or loading operations.

* Heavy-Duty Wheels: High-durability wheels designed to withstand continuous operation on rough or irregular rail surfaces.

10. Eco-Friendly Options:

* Regenerative Braking: Energy-saving options such as regenerative braking, which converts excess energy into usable power.

* Reduced Emission Systems: Low-emission or emission-free operation, depending on regional regulations and environmental impact goals.

11. Auxiliary Attachments:

* Magnetic or Vacuum Lifters: Specialized attachments for handling steel plates, sheet metal, or other non-containerized loads.

* Custom Lifting Attachments: Options for custom hooks, spreader bars, or lifting slings to handle a variety of load types, from containers to oversized cargo.

Packing & Delivery

A: An RMG crane is a type of gantry crane that moves along a fixed rail system. It is commonly used in container yards, rail yards, and industrial applications for stacking, loading, and unloading heavy cargo.

2. Q: What types of applications are RMG cranes best suited for?

A: RMG cranes are ideal for high-density container stacking, rail cargo handling, and bulk cargo operations, as well as in

environments where precise movement and efficient space utilization are essential.

3. Q: How does an RMG crane differ from a Rubber Tyred Gantry (RTG) crane?

A: The main difference is in mobility: RMG cranes are rail-mounted and follow fixed paths, while RTG cranes are rubber-tired and can move freely around a yard.

4. Q: Can an RMG crane be customized for specific operational needs?

A: Yes, RMG cranes can be customized for various specifications, including load capacity, span width, lifting height, speed, power supply, and control system options.

5. Q: What control options are available for RMG cranes?

A: RMG cranes can be operated via a cab, remote control, or fully automated control systems, depending on the required precision and operational preference.

6. Q: What kind of rail infrastructure is required for an RMG crane?

A: RMG cranes require a stable rail system with compatible gauge and length. The rail should be installed according to load requirements and environmental conditions to support safe and stable crane movement.

7. Q: Are there anti-sway features for RMG cranes?

A: Yes, anti-sway technology can be integrated to stabilize loads and ensure precise placement, which is essential in

high-density stacking and for safety.

8. Q: What maintenance is required for an RMG crane?

A: Regular maintenance includes checking and lubricating rails, inspecting the electrical systems, and routine inspections of llifting components and load handling tools. Maintenance frequency depends on operational demands and environmental exposure.

9. Q: How long is the lifespan of an RMG crane?

A: With proper maintenance, RMG cranes can operate efficiently for 20 to 30 years or more, depending on the operational environment and usage frequency.

10. Q: Can an RMG crane be integrated with yard management systems?

A: Yes, modern RMG cranes can integrate with digital yard management systems for tracking, automation, and enhanced operational efficiency.

11. Q: How do RMG cranes contribute to reducing operational costs?

A: RMG cranes reduce operational costs by improving efficiency, reducing energy consumption, and enabling better space utilization in container yards and industrial facilities.

12. Q: What should be considered when choosing an RMG crane?

A: Key factors include load capacity, span, lifting height, environmental conditions, safety features, control systems, and the layout of the yard or facility where it will be used.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices