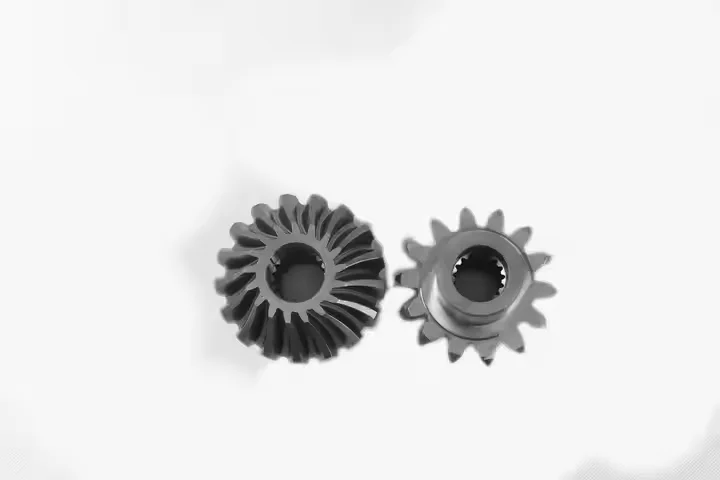

High Precision Spiral Bevel Gears for Forging Services Wholesale from China Supplier Hardened Machinery Bevel Gears

- Category: >>>

- Supplier: Henan Forging Emperor Industry Co. Ltd.Henan Ltd.

Share on (1601286997658):

Product Overview

Description

| Item name | Custom Forging Parts |

| Size | As per approval product drawings |

| DRW Format | DWG,PDF,IGS,STEP,SLDPRT,SLDDRW,PRT,DRW,DXF,X_T,etc... |

| Weight | 0.1-200kg |

| Material | Differernt types of steel,Carbon steel,Stainless steel,Alloy Steel,Aluminum alloy,copper alloy,titanium alloy,tungsten molybdenum alloy and other non-ferrous matals. |

| Surface treatment | Self color,Polishing,Painting,Powder coating,Electrophoretic coating,Anodizing,Nickel plating,Zinc planting,Hot dip galvanizing etc... |

| Quality Control | 1.Raw materials test,include chemical composition and size 2.Random inspection during production 3.Final products size test,with measurement tools,special gauges and coordinate insteument if needed 4.Final products strenght and hardness test,to guarantee the machanical property 5.Assembly and function test,with special testing gauges 6.Packing test |

| Logistics | Shipping,Air flight,International express etc... |

| Process | Die forging,Free forging,Hot forging,Cold forging,Heat Treatment,Machining,Surface treatment etc... |

| Certificate | ISO/9001 ISO/IATF16949 |

Plastic bags, Cartons, Racks, Plywood Cases etc

Plastic bags, Cartons, Racks, Plywood Cases etc

The company has a professional industrial design department,which can design department,which can design products according to customers' requirements or make secondary design improvements or make secondary design improvement on old products to achieve optimal product.Custom OEM/ODM metal parts processing, Whole Product assembly, 2D & 3D drawings design, International Delivery Logistics, Serivce before & after sales etc.

Our advantages

The products are made in conformity with the international standard(DIN,ANSI and BS),advanced technology and perfect management system for quality control,Gear reputation spreads in North American,Europe,Australia and so on.

The main forging equipment includes: Friction press production line of 4000T,1600T,630T and 300T with assistant of molds processing machines.100KJPJ PLC hydraulic forging hammer,2T&3T Electro hydraulic hammer,Type 250,450&650 Vertical Ring Rolling Machines.Heat treatment equipment Includes:medium frequency induction heating furnace,Continuous tempering furnace,1000KG/Hour No oxidation isothermal normalizing furnace.With current equipment,we can produce forging parts from 0.1kg to 120 kg

The machining factory is fully equipped with complete and advanced CNC machining equipment including 20 vertical and horizontal machining centers and more than 30 NC machines, the machining facility is fully independent from the forging foundry and has an independent management team and tailored business model to suit.

Quality Control:

The company regards quality as cooperate life,as here to high standard and and high quality.We got ISO9001:2008 and TS16949 system,also sets up the consummate testing system,perfects quality assurance system,implements the rigid quality management,our aim is to realize zero defect,ensure each product to satisfy user.

The main testing equipment includes:3-coordinate measuring machine,Optical Spectrum Analyzer,tensile testing machine,impact testing machine,fluorescent magnetic particle detector,hardness tester,ultrasonic flaw detector..etc.

Material Inspection:

Ordering material is the first step to make steel forgings, and to ensure the material is what we need, we will require material certificate from material factory.

Only material certificate in not enough, after the materials are delivered to our factory,our technical person will also cut a small piece to test the chemical composition by spectrum analyzer, and check if each tested composition is within the range of elements.

Besides, after forging, we will also inspect the forging blanks to see if the material composition will change.

Dimentional Inspection:

Dimentional inspection is the most important job for custom steel forgings. Any dimension and tolerance error may cause the product unusable. To guarantee the final assembly, the dimensions and tolerances of steel forgings should be as accurate as possible. So our quality inspector will be in charge of dimentional inspection after products are finished.

One way is to testing instruments, such as callipers, depth gage, dial indicator, inside micrometers, height gauge, ect. These will be done by hand operation. For more accurate dimensions, CMM can be used. But only few companies have this instrument for the high price.

As the usage of all these custom steel forgings will be assembled into the machines, so sometimes, it is difficult to inspect some dimensions, to ensure the products can be applied when our customers receive them, we will make a guage/fitting to test if there is any assembling problem.

Mechanical Properties Inspection:

For some special usage or application, there will be some mechanical properties requirements (such as hardness, tensile strength, ect) of the products. According to the needed properties, we will perform heat treatment service after closed die forging. And confirm the expected properties, mechanical testing will be operated to prove the quality of steel forgings. Below are some common inspections about the mechanical properties:

Hardness Testing-Is tested when there is a hardness requirement on steel forgings. The hardness will be tested by brinell or rockwell hardness tester.

Tensile Testing-A destructive test process that provides ultimate tensile strength, yield strength, elongation and reduction area rate of the products.

Defects Inspection:

Although the strength of steel forgings are much better than steel forgings, it may also exsit defects, we can distinguish the defects into surface defects and inner defects.

For surface defects such as trimming, cold shut, dents, ects, are mainly tested by 100% visual inspection or MPI(Magnetic particle inspection). But MPI cost is high, which is done when it is requested by our customer, of course, customers will be in charge of the cost.

Inner inspection is needed especially when steel forgings are used in safety and strength considerations. Inner inspection of steel forgings include:

NDT(Non Destructive Testing): X-ray, UT(ultrasonic testing), ect. This is the most direct way to test the inner defects of products.

Section test:

Another direct way to see if there is inner defect inside the products is to do section test, and inspect the defects by visual.In this way the products will be broken, and could not be used any longer.

As the usage of all these custom steel forgings will be assembled into the machines,so sometimes, it is difficult to inspect some dimensions, to ensure the products can be applied when our customers receive them, we will make a guage/fitting to test if there is any assembling problem.

Quality consciousness:

Quality means for us satisfaction of our interest partners as customer, supplier and personnel as well as fulfilment of applicable legitimate and regulatory requirements.

The commercial success of our company results from the ability, which includes conforming the requirements and expectations of our customers precise, on schedule and cost efficient simultaneously to high flexibility.

To act quality conscious means for us also dealing with worthwhile resources efficiently and with consideration. The continuing advancement of quality is for us a mid- and long- term condition, because it allows us to lower the costs and helps preventing environment from damage.

We Recommend

Forged Wheels 5x120

Forged 20mm-150mm Steel Ball for Ball Mill

Half Sphere Dished End for Fire Pits

New Arrivals

New products from manufacturers at wholesale prices