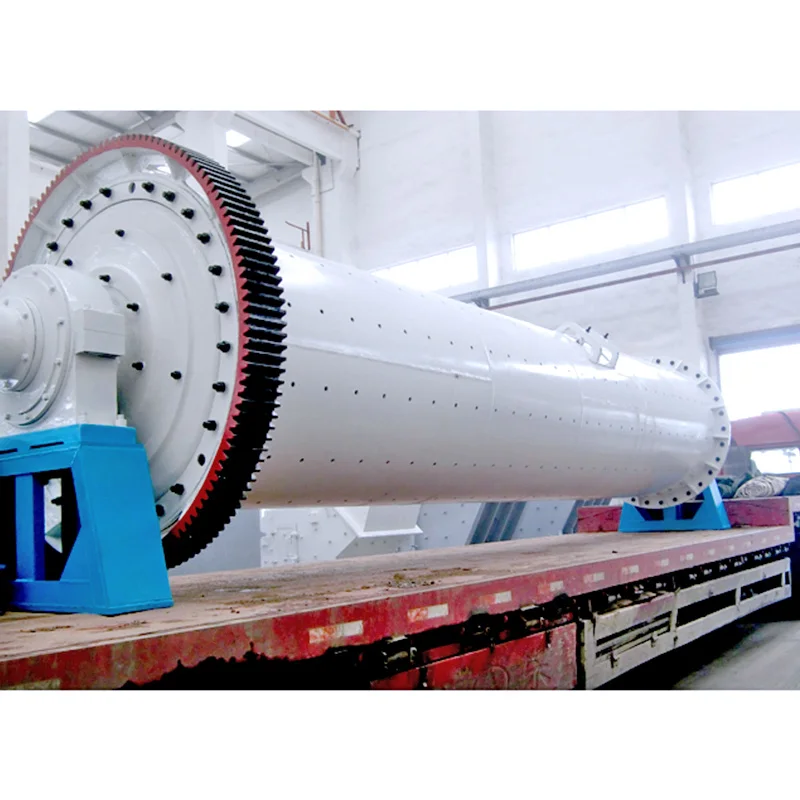

energy saving 900x3000 Ore Ball Mill Equipment Manganese Gold Copper Iron Zinc Tin Iron Ore Wet Ball Mill

- Category: >>>

- Supplier: Henan Kolev Equipment Technology Co. LtdHenan Ltd

Share on (1601287819093):

Product Overview

Description

High Efficient Dryer Wet Ceramic Ball Mill Grinding Silica Sand Quartz Stone Clay

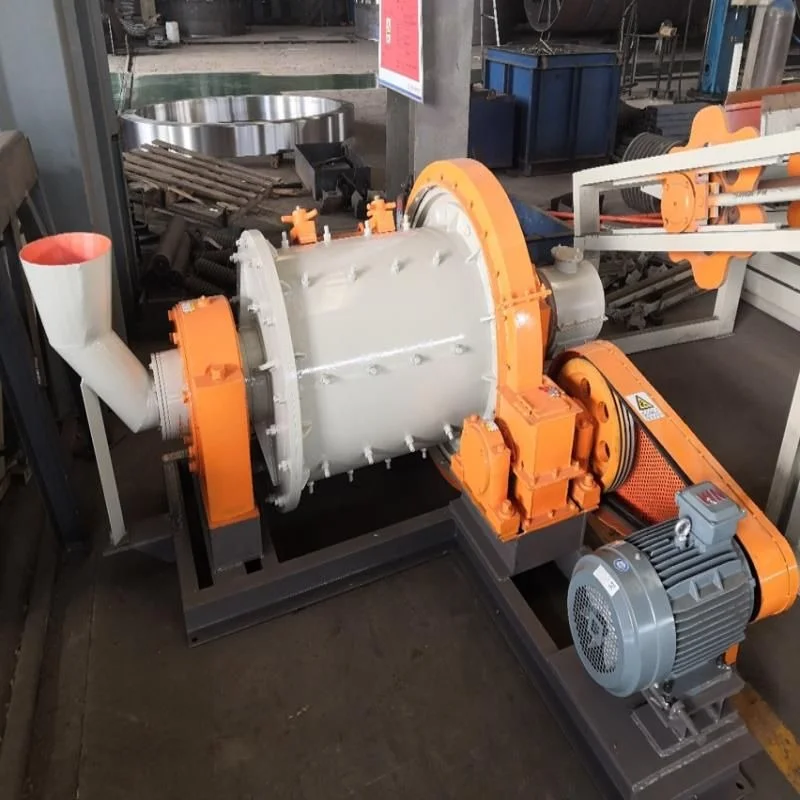

Batch Ball Mill Introduction

Batch ball mill is a small non-continuous production mill. With simple structure, easy operation, less auxiliary equipment, it can once obtain high fineness products. It can adopt dry-milling with special product collection hopper and also wet milling with slurry discharge valve. The batch ball mill is applied to the production line with high fineness requirements or small production line with special materials.

Batch ball mill is a small non-continuous production mill. With simple structure, easy operation, less auxiliary equipment, it can once obtain high fineness products. It can adopt dry-milling with special product collection hopper and also wet milling with slurry discharge valve. The batch ball mill is applied to the production line with high fineness requirements or small production line with special materials.

Model | Capacity (t/h) | Cylinder speed (r/min) | Motor power (kw) | Weight (t) |

TCQ910×1120 | 0.2 | 36 | 5.5-11 | 3.0 |

TCQ1200×1400 | 0.5 | 32 | 11-18.5 | 3.8 |

TCQ1500×1800 | 1.0 | 28 | 15-22 | 4.5 |

TCQ1800×2100 | 1.5 | 26 | 18.5-30 | 6.0 |

TCQ2100×2100 | 2.5 | 22 | 22-37 | 7.4 |

TCQ2500×2900 | 5.0 | 16 | 37-55 | 9.3 |

TCQ2800×3700 | 8.0 | 14.5 | 55-75 | 12.5 |

TCQ3000×3700 | 10 | 14 | 75-90 | 18.6 |

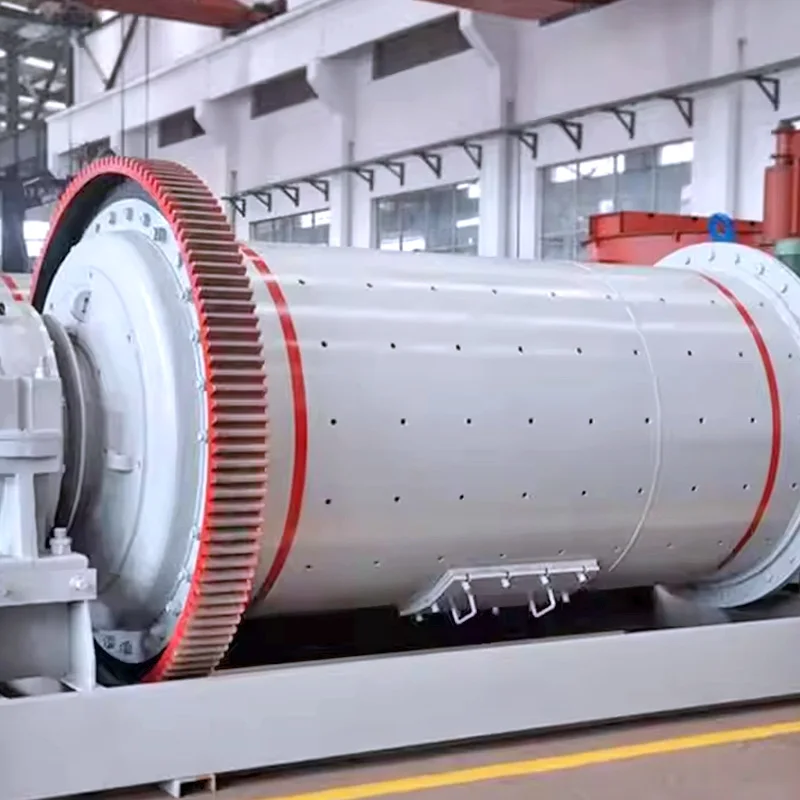

CERAMIC BALL MILL STRUCTURE

The ceramic ball mill is a horizontal cylinder ball mill. It is composed of the feeding part, discharging part, rotary part, transmission part (reducer, transmission gear, motor, and electrical control device), lining plate, grinding medium, and other components. The quill shaft is made of steel casting and the lining plate is detachable.

HIGHLIGHTS OF CERAMIC BALL MILL

1.Various Lining Plate Types

Customers can choose different types of lining plates according to raw material gravity, hardness, and other factors.

2.Small Space Occupation

The length of the ceramic ball mill is short so it occupies a small area. To some extent, it reduces the cost of land investment.

3.Uniform Particle Size

The grinding fineness of the ceramic ball mill is adjustable. The oversize particles will be screened out and sent back to the

grinding chamber.

4.Energy-saving & High Output

Compared with traditional equipment, the output of the ceramic ball mill is 25% higher, the power consumption is 26% lower, and

the grinding medium consumption is also less.

5.No Abnormal Noise

The ceramic ball mill adopts new technology to reduce the resistance inside the machine, therefore, the ball mill ventilation is

smooth and the product particle size distribution is reasonable. There is no abnormal noise and unstable factors during the operation.

6.Steady Running

The use of modified gear can reduce the sliding speed and sliding ratio of the meshing, thus advancing the wear-resistant and anti-scuffing performance of the gear, enhancing the lubrication state of the gear transmission, and improving the reliability of the ceramic ball mill.

Customers can choose different types of lining plates according to raw material gravity, hardness, and other factors.

2.Small Space Occupation

The length of the ceramic ball mill is short so it occupies a small area. To some extent, it reduces the cost of land investment.

3.Uniform Particle Size

The grinding fineness of the ceramic ball mill is adjustable. The oversize particles will be screened out and sent back to the

grinding chamber.

4.Energy-saving & High Output

Compared with traditional equipment, the output of the ceramic ball mill is 25% higher, the power consumption is 26% lower, and

the grinding medium consumption is also less.

5.No Abnormal Noise

The ceramic ball mill adopts new technology to reduce the resistance inside the machine, therefore, the ball mill ventilation is

smooth and the product particle size distribution is reasonable. There is no abnormal noise and unstable factors during the operation.

6.Steady Running

The use of modified gear can reduce the sliding speed and sliding ratio of the meshing, thus advancing the wear-resistant and anti-scuffing performance of the gear, enhancing the lubrication state of the gear transmission, and improving the reliability of the ceramic ball mill.

Recommend Products

Jaw crusher

Pulse dust collector

Belt conveyor

Cooperation cases

FAQ

Q1: Are you factory or trading company?

A1: we are factory, Self-produced and self-sold.

Q2: How about the quality of your products?

A2: No one pays more attention to product quality than we do,our boss is technical background, he is not a businessman, he often says that manufacturing inferior product is equal to producing garbage,This slogan has been hung in our production workshop.

Q3:Do you provide complete solutions?

A3: Yes,we provide kinds of solutions in drying, milling, crushing and sand making area! And we are professional!

Q4:How is your company's financial situation

A4:The company's operation is excellent without any debts and loans, and the plant and land have property rights

Q5:Do your company has any certification

A5:At present, we have 26 utility model patents and many invention patents

Q6:How about the after-sale service?

A6:12 months warranty for all kinds of products.

Q7: How to get the free solution and quotation ?

A7: Please send inquiry to us ,leave your whatsapp and email , our sales manager will contact you as soon as possible

Q2: How about the quality of your products?

A2: No one pays more attention to product quality than we do,our boss is technical background, he is not a businessman, he often says that manufacturing inferior product is equal to producing garbage,This slogan has been hung in our production workshop.

Q3:Do you provide complete solutions?

A3: Yes,we provide kinds of solutions in drying, milling, crushing and sand making area! And we are professional!

Q4:How is your company's financial situation

A4:The company's operation is excellent without any debts and loans, and the plant and land have property rights

Q5:Do your company has any certification

A5:At present, we have 26 utility model patents and many invention patents

Q6:How about the after-sale service?

A6:12 months warranty for all kinds of products.

Q7: How to get the free solution and quotation ?

A7: Please send inquiry to us ,leave your whatsapp and email , our sales manager will contact you as soon as possible

We Recommend

Laboratory Industry Planetary Ore Ball Mill Machine

$4,500.00-5,000.00

Oil Coke Grinding Mill With European Certification

$4,900.00-5,000.00

Ce Attritor Aluminum Powder Ball Mill

$12,400.00-18,600.00

New Arrivals

New products from manufacturers at wholesale prices