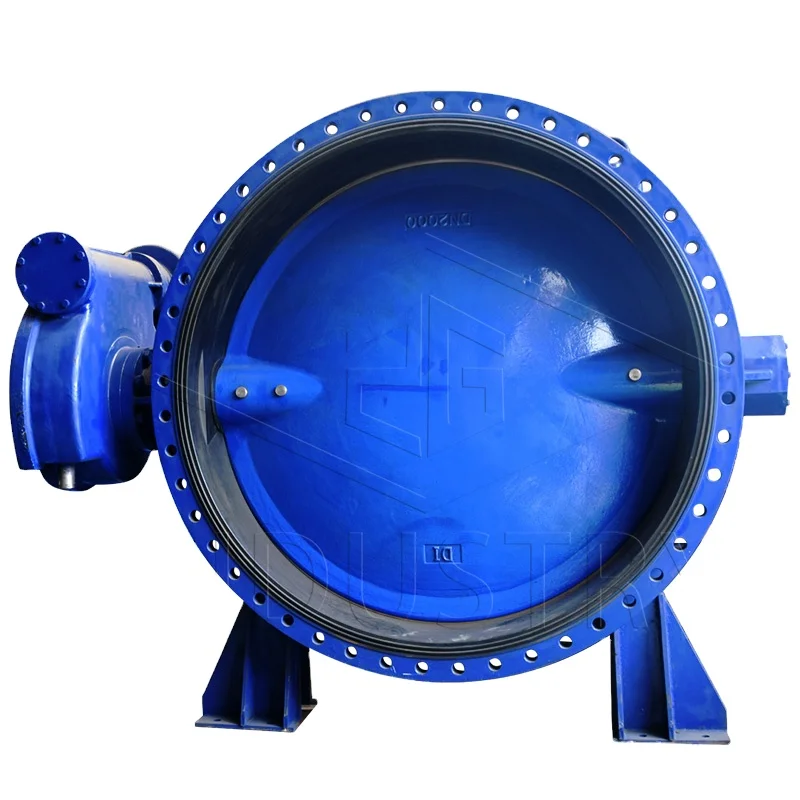

Good Quality High Temperature and Corrosion Resistant Gear Large Size Fanged Butterfly Valve for Compressed Air

- Category: >>>

- Supplier: Zhangguo Industry Co. Ltd.Zhangguo Ltd.

Share on (1601290188535):

Product Overview

Description

Products Description

Large size flanged butterfly valve

ZG flange butterfly valve (DN32-DN3200), pressure: PN6~PN25, class125/150,15 years of production

experience, 100% pressure test, 10 inspection procedures,all ZG valves have passed CE pressure equipment certification.

experience, 100% pressure test, 10 inspection procedures,all ZG valves have passed CE pressure equipment certification.

Size Range: DN40-DN3200

Pressure: 10K/150LB/PN10/PN16

Body Materials: Cast Iron, Ductile iron, WCB, SS304, SS316, SS304L, SS316L, Bronze,Aluminum Alloy

Seat Materials: EPDM, NBR, PTFE, VITON, Rubber

Disc Materials: Ductile Iron, WCB, SS304, SS316, SS304L, SS316L,Bronze, Aluminum Alloy

Stem/Shaft Materials: 45#, 410, 420, 431, 304, 304L, 316, 316L, Bronze, Monel, Hard alloy

Pin: Stainless Steel

Bushing: PTFE, Bronze

O-Ring: EPDM/NBR//Viton

Payment: T/T, D/P or L/C

Lead Time: 5-30 days

Description

Design Features:

1. Novel design structure, small overall size and light weight.

2. Usually the torque is small, the opening and

closing is quick, and the operation is light and labor-saving.

closing is quick, and the operation is light and labor-saving.

3. The butterfly plate and the sealing ring are tightly combined,

which can achieve zero leakage.

which can achieve zero leakage.

4. Flange butterfly valve connection requires shorter bolts than wafer butterfly valve, which is more reliable in the application of large-diameter pipelines. Generally, flange butterfly valve or U-shaped butterfly valve is recommended for large-diameter working conditions.

Field of Application:

Operating Temperature:

NBR: 0℃~+90℃EPDM: - 20℃~+120℃PTFE: -10℃~+150℃

Operate:

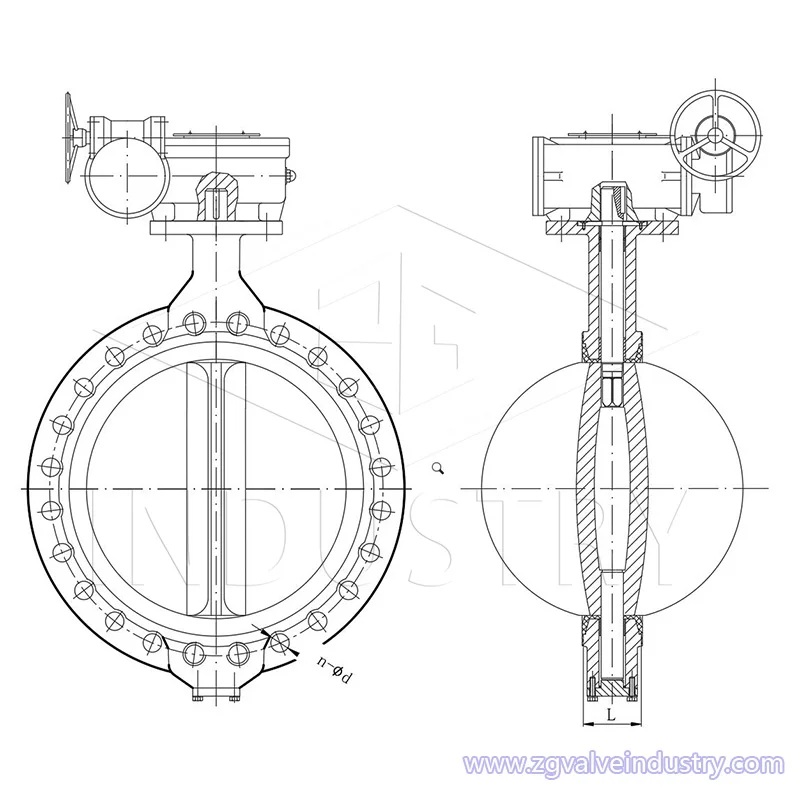

DN32-DN250: LeverDN300-3200: Worm gear

Optional operation: Lever, Worm gear, Pneumatic, Electric-Motorized

Application: Chemical processing, Desalination plants, Drinking water, Dry powder, Food and beverage, Gas plants, HAVC Mining industry, Paper industry, Sand handling, Seawater, Sugarindustry, Thermo technical water treatment, Waste water, Cooling Water Circulation, Compressed Air

Technical Specification:

Design Standard:EN 593, MSS SP67, API 609, BS5155Face to Face dimension: ISO 5752, EN 558, MSS SP67, API

609, DIN3202

609, DIN3202

End Standard:ANSI B16.1 Class125LB & B16.5 Class150LB AS 2129 Table D & E BS 10 Table D & EDIN 2501 PN6, PN10 & PN16EN 1092 PN6, PN10 & PN16ISO 2531 PN6, PN10 & PN16ISO 7005 PN6, PN10 & PN16KS B 1511 / JIS B 2210 5K & 10KMSS SP44 CL. 150LB AWWA C207 SABS 1123 Table 1000/3 & Table 1600/3

Top Flange: ISO5211

Test standard: API 598, ISO 5208, EN 12266

Material Specification | ||

Part Name | Material | |

Body | Cast Iron, Ductile iron, WCB, SS304, SS316, Bronze, Aluminum Alloy | |

Disc | Ductile Iron, CF8, CF8M, WCB, Bronze, Aluminum Alloy | |

Seat | EPDM, NBR, PTFE, VITON, Rubber | |

Stem | 45#, 410, 420, 431, 304, 304L, 316, 316L, Bronze, Monel, Hard alloy | |

Size | L mm | Top Flange | ANSI CL150 | DIN PN10 | PN16 | ||||||||

DN mm | Inch | PCD | n-φd | PCD | n-φd | PCD | n-φd | ||||||

50 | 2" | 108 | 32 | 120.5 | 4-19 | 125 | 4-18 | 125 | 4-18 | ||||

65 | 22/1" | 112 | 32 | 139.5 | 4-19 | 145 | 4-18 | 145 | 4-18 | ||||

80 | 3" | 114 | 32 | 152.5 | 4-19 | 160 | 8-18 | 160 | 8-18 | ||||

100 | 4" | 127 | 32 | 190.5 | 8-19 | 180 | 8-18 | 180 | 8-18 | ||||

125 | 5" | 140 | 32 | 215.9 | 8-22.4 | 210 | 8-18 | 210 | 8-18 | ||||

150 | 6" | 140 | 32 | 241.5 | 8-22.4 | 240 | 8-22 | 240 | 8-22 | ||||

200 | 8" | 152 | 45 | 298.4 | 8-22.4 | 295 | 8-22 | 295 | 12-22 | ||||

250 | 10" | 165 | 45 | 361.9 | 12-25.4 | 350 | 12-22 | 355 | 12-26 | ||||

300 | 12" | 178 | 45 | 431.8 | 12-25.4 | 400 | 12-22 | 410 | 12-26 | ||||

350 | 14" | 190 | 45 | 476.2 | 12-28.4 | 460 | 16-22 | 470 | 16-26 | ||||

400 | 16" | 216 | 51 | 539.7 | 16-28.4 | 515 | 16-26 | 525 | 16-30 | ||||

450 | 18" | 222 | 51 | 577.8 | 16-31.8 | 565 | 20-26 | 585 | 20-30 | ||||

500 | 20" | 229 | 57 | 635 | 20-31.8 | 620 | 20-26 | 650 | 20-33 | ||||

600 | 24" | 267 | 70 | 749.5 | 20-35.1 | 725 | 20-30 | 770 | 20-36 | ||||

700 | 28" | 292 | 66 | 863.6 | 28-35.1 | 840 | 24-30 | 840 | 24-36 | ||||

800 | 32" | 318 | 66 | 977.9 | 28-41.1 | 950 | 24-33 | 950 | 24-39 | ||||

900 | 36" | 330 | 118 | 1085.8 | 32-41.1 | 1050 | 28-33 | 1050 | 28-39 | ||||

1000 | 40" | 410 | 142 | 1200.2 | 38-41.1 | 1160 | 28-36 | 1170 | 28-42 | ||||

1200 | 48" | 470 | 150 | 1422.5 | 44-41.1 | 1380 | 32-39 | 1390 | 32-48 | ||||

We Recommend

New Arrivals

New products from manufacturers at wholesale prices