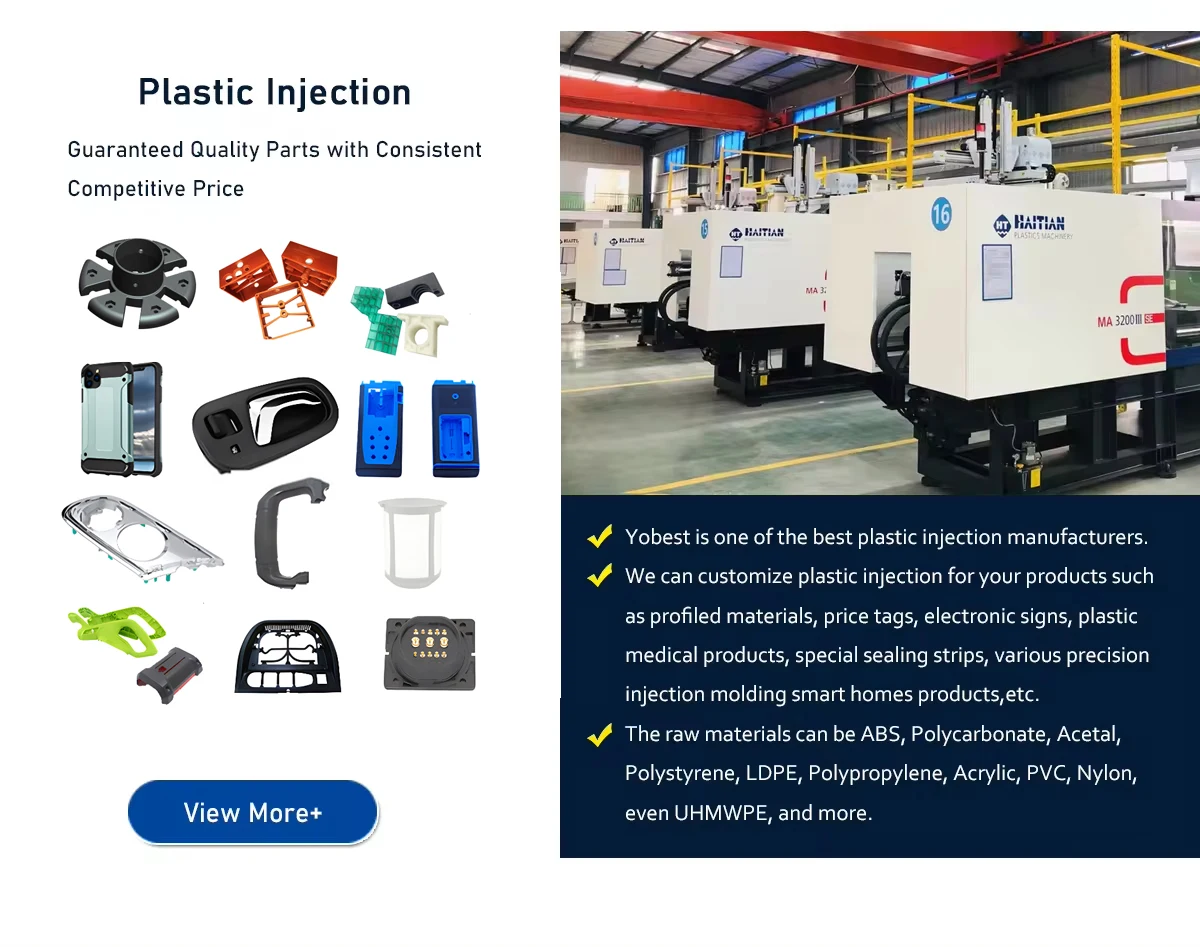

China ABS injection plastic of injection machine molded small plastic parts

- Category: >>>

- Supplier: Fujian Yobest New Material Co. Ltd.Fujian Ltd.

Share on (1601290755753):

Product Overview

Description

Item | Custom Plastic Injection Mould |

Part Material | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

Certificate | IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 |

Drawing Format | .stp / .step / .igs /.stl /.dwg / .pdf |

Mold Material | S136H, 718H, 2343, 8407, NAK80, P20, H13, #50 steel, etc |

Mold Precision | Depends on the product tolerance request. |

Mold Life-cycle | 100,000-500,000 shots. |

To be discussed | In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold,Collapsible Core Mold, Die Sets, Compression Mold, Cold Runner System LSR Mold,...etc. |

Surface Finish | Texture(MT standard), High gloss polishing |

Design & Program Softwares | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc. |

Equipments | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available |

Product Design

We Provide Product Design Service As Customer's Request.

Mold Design

We will communicate&exchange the opinion with customers during Mold Deisgn

Mold Making

Start to manufacture, we will sent photos to show tooling process

Provide the sample

Once the sample finish,we will send the sample to customer confirm

Mass Production

After customer confirmed the sample, we will start mass production plastic products.

Assembly

We Also Provide Assembly Service For Our Customer

Painting&Coating

We can provide coating and rubber coating service for your customers.

Printing

We Also Provide Silk Screen Printing, Pad Printing, Heat Transfer Print Service.

Packaging Box

We also make the packaging box as customer request

Custom plastic parts product injection moulding services

1. Start from part design analysis.

1. Start from part design analysis.

2. Mold design drawing and DFM report available so you can see how is the mold going to be before mold making.

3. If product is complex,moldflow report will be present as well.

4. In house mold making shop ensure you mold quality under well control.

5. Normally it takes 20-40 days to make mold,precise time depends on part design.

6. Injection molded parts can be different material such as ABS/PC/PP/HDPE/POM/PA6/PA6+GF/PVC/NYLON/PMMA/PET Ect.

7. Yobest can also provide different surface treatment for injection molded parts.

8. Commonly use surface treatment for injection molded parts as:Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy/VDI.

9. Beside making injection molded parts,we also provide printing,welding,assembly and packing service.

3. If product is complex,moldflow report will be present as well.

4. In house mold making shop ensure you mold quality under well control.

5. Normally it takes 20-40 days to make mold,precise time depends on part design.

6. Injection molded parts can be different material such as ABS/PC/PP/HDPE/POM/PA6/PA6+GF/PVC/NYLON/PMMA/PET Ect.

7. Yobest can also provide different surface treatment for injection molded parts.

8. Commonly use surface treatment for injection molded parts as:Texture/Sandy/MT/YS/SPI/EDM finish/smooth/glossy/VDI.

9. Beside making injection molded parts,we also provide printing,welding,assembly and packing service.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices