Abrasives material granulated copper slag blasting grit for factory sale price

- Category: >>>

- Supplier: Xiamen Daxing Industry Co. Ltd.Xiamen Ltd.

Share on (1601291156951):

Product Overview

Description

Products Description

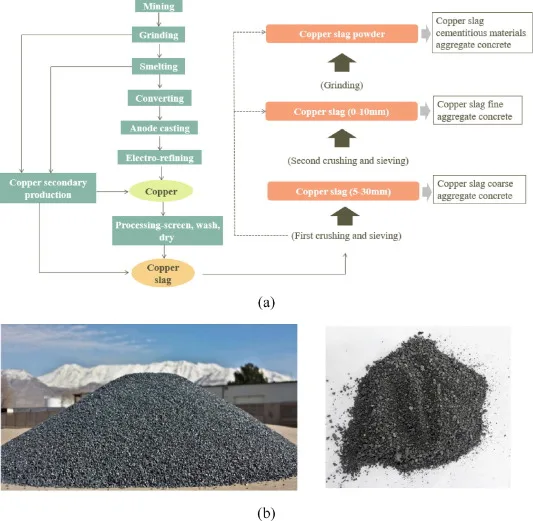

* Copper slag is a byproduct obtained during smelting and refining of copper ore rich in sulphides and oxides of iron and copper, in the course of removing iron as iron silicate. During the smelting process at 1250°C, copper liquid settles down due to higher density while copper slag remain on the surface in the segregated state. The copper slag is then collected and cooled with jets of pressurised water. The associated thermal shock creates a unique, glassy amorphous granulate. During the manufacture of the abrasive no crushing or grinding procedures are included. Therefore, the single abrasive particle is not broken up and retains its extreme hardness and tenacity which is the case for all particle sizes. Further, to obtain maximum blasting operating results, the particles are washed multiple times and carefully screened on different grain sizes.

Grade Size | Nominal Size | Normal Application |

G830 | 0.50 – 3.35 MM, approx. | Removal of heavily rusted surfaces |

G830E | 0.50 – 2.00 MM, approx. | Removal of heavily rusted surfaces |

G1430 | 0.50 – 1.18 MM, approx. | Removal of old coatings & rusting mill scales |

G3060 | 0.25 – 0.60 MM, approx. | Removal of rusting mill scales & preparation of new steel |

DX BLAST Co., Ltd. (JX Blasting), with 30 years development, is a professional manufacturer of shot blasting machines and shot peening machines.

DX BLAST, distribution network consists of sales agents from many countries as Poland. Mexico. UAE. Saudi Arabia. Malaysia, Vietnam. Philippines, Pakistan, Indonesia

DX BLAST, distribution network consists of sales agents from many countries as Poland. Mexico. UAE. Saudi Arabia. Malaysia, Vietnam. Philippines, Pakistan, Indonesia

COOPERATE WITH THE BRANDS

CERTIFICATE

Intelligent designs ,innovative details and particularly durable components --- that is what our shot blasting equipment stands for .

There are our customers from all over the world to visit us and consult surface treatment issues .

DX BLAST , attend the professional event & show of surface treatment as : Gifa Düsseldorf in Germany , Tube Arabia , Steel FAB in UAE , Saudi Build , Metal Expo in Moscow, Metal& steel in Saudi , Metalex , MTA HANOI in Vietnam , Fundiexpo in Mexico , Inometal in indonesia , PDMEX in Philippine .....

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

1. Small spare parts put in plywood wooden cases

2. Other parts is our company standard or according to customer requirements

3. Shipping: Container transport

2. Other parts is our company standard or according to customer requirements

3. Shipping: Container transport

FAQ

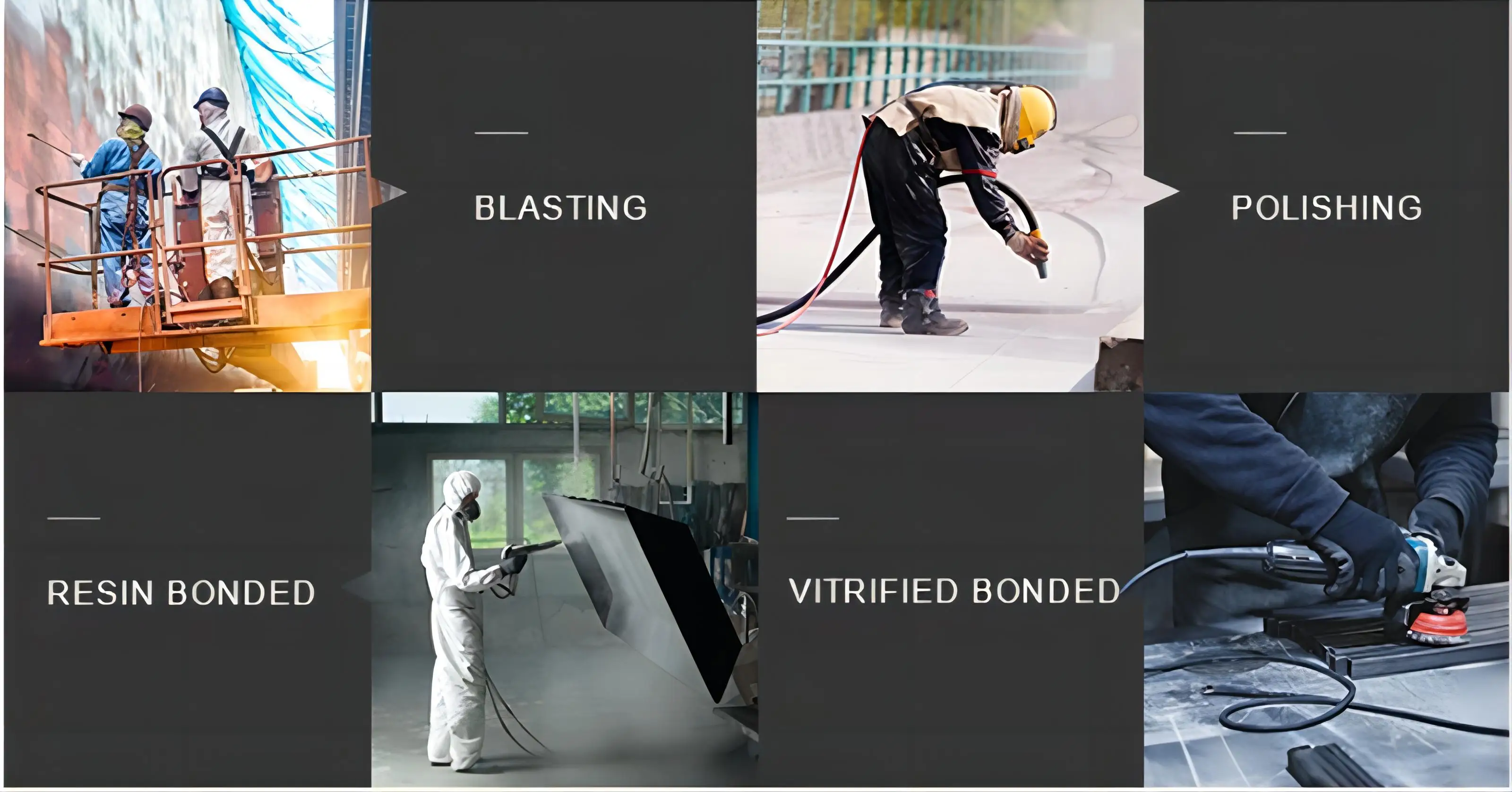

Q1. For this particular job, will abrasive blasting be used for surface preparation or as a cleaning procedure?

Q4. If blasting for surface preparation, what surface profile is required?

All coatings have a recommended surface profile (roughness) specification. Excess surface profile can shorten the life of a thin-film, low-build coatings, insufficient profile can cause delamination of high-build coatings.

Q5. Will coating adhesion be affected by surface contamination?

Some abrasives leaving a cleaner surface than others, which can have a substantial impact on coating adhesion.

The difference between these two procedures are as follows:

* When abrasive blasting is used as a surface preparation technique, the intention is to remove all surface contaminants and also prepare the substrate to receive a coating.

* When abrasive blasting is to be used as a cleaning procedure, then the intention is to remove the surface contaminants, while leaving the substrate untouched.

Q2. Will it be possible to reclaim and recycle the abrasive, or will it have a single use only?

The major deciding factor here is cost. The cost of abrasives, while very effective, are uneconomical to use if recycling is not an option.

Q3. Will the worksite be dust sensitive?

The amount of dust generated by different abrasives varies widely. Some excellent types of abrasives are available that are specifically graded to reduce dust.

* When abrasive blasting is used as a surface preparation technique, the intention is to remove all surface contaminants and also prepare the substrate to receive a coating.

* When abrasive blasting is to be used as a cleaning procedure, then the intention is to remove the surface contaminants, while leaving the substrate untouched.

Q2. Will it be possible to reclaim and recycle the abrasive, or will it have a single use only?

The major deciding factor here is cost. The cost of abrasives, while very effective, are uneconomical to use if recycling is not an option.

Q3. Will the worksite be dust sensitive?

The amount of dust generated by different abrasives varies widely. Some excellent types of abrasives are available that are specifically graded to reduce dust.

Q4. If blasting for surface preparation, what surface profile is required?

All coatings have a recommended surface profile (roughness) specification. Excess surface profile can shorten the life of a thin-film, low-build coatings, insufficient profile can cause delamination of high-build coatings.

Q5. Will coating adhesion be affected by surface contamination?

Some abrasives leaving a cleaner surface than others, which can have a substantial impact on coating adhesion.

Q6. Which abrasive provides the maximum productivity?

Abrasive particle size and shape all have an effect on blasting speed. Some factors to consider:

* The ideal abrasive size is where the largest particle is equal to the size of the thickness of the coating to be removed. If the particle size is too large, the “hit rate” is reduced because the grain count in the pot is lowered. If the particle size is too small, the speed of cutting through the old surface is reduced.

* Grain toughness is a term given to describe it’s durability and recyclability. A tougher grain converts more energy into the removal of the old coating, while a weaker grain is more likely to disintegrate on impact.

* Particle shape can either be rounded or angular. The more rounded the particle is, the more contact area it has, which increases the surface removal speed.

* The ideal abrasive size is where the largest particle is equal to the size of the thickness of the coating to be removed. If the particle size is too large, the “hit rate” is reduced because the grain count in the pot is lowered. If the particle size is too small, the speed of cutting through the old surface is reduced.

* Grain toughness is a term given to describe it’s durability and recyclability. A tougher grain converts more energy into the removal of the old coating, while a weaker grain is more likely to disintegrate on impact.

* Particle shape can either be rounded or angular. The more rounded the particle is, the more contact area it has, which increases the surface removal speed.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices