Automatic Feeder Thin Blade Slitter Scorer Machine With Stacker

- Category: >>>

- Supplier: Cangzhou Xiaoyuan Carton Machinery Trading Co. Ltd.Cangzhou Ltd.

Share on (1601292130418):

Product Overview

Description

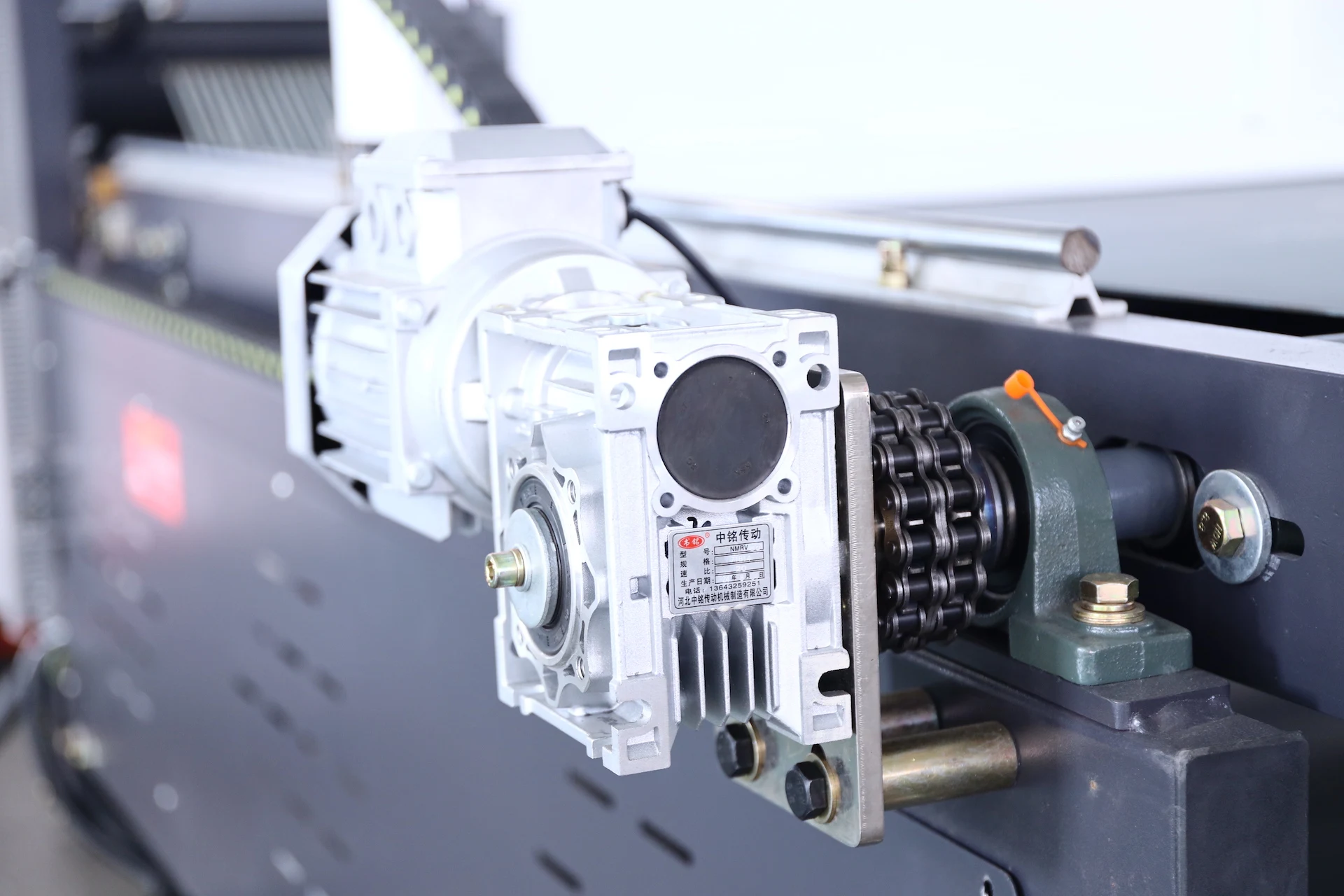

Main configuration:

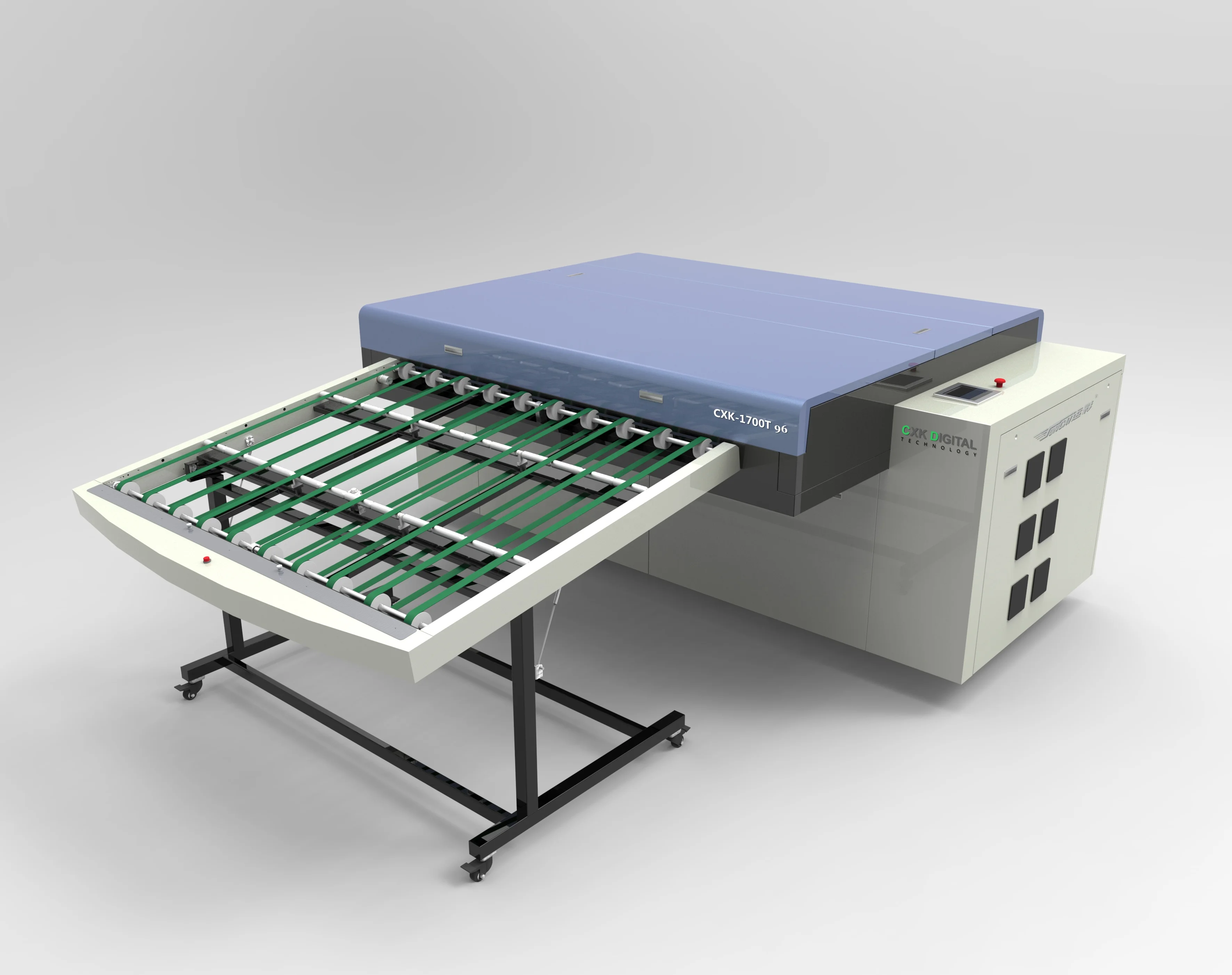

1.Man-machine interface - PLC control, cutting cardboard, ordering are independent stepper motor control, automatic scheduling order speed 1-10 seconds, error accuracy ±0.5 mm.

2.The operation is very humanized, high-tech, ordinary workers can operate.

3.Slitting part: Using high-quality tungsten steel alloy blade, long service life, slitting out the cardboard incision neatly without fracturing, no burrs.

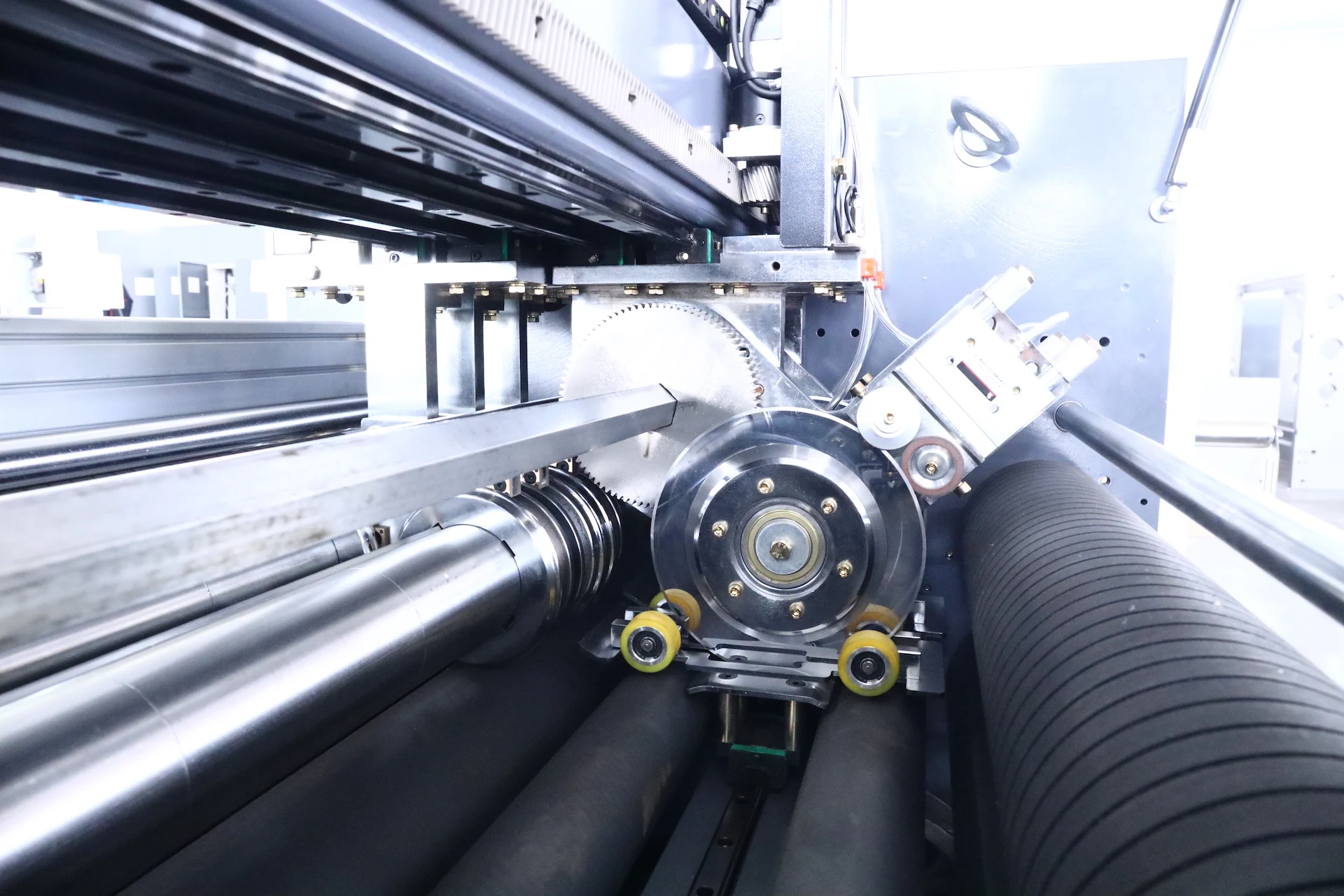

4.Both sides of the thin slitter scorer machine use rubber wheels to press cardboard to overcome the phenomenon of no pressure line, deviation and poor straightness when cutting the board alone.

5.The knife sharpening device adopts automatic and manual pneumatic knife sharpening methods, which can work while sharpening the knife and improve the work efficiency.

6.Electrical appliances are made of domestic brands or imported products with reliable performance.

7.This machine can store 999 groups of orders, to achieve non-stop order change and manual order change.

8.With automatic paper feed table to adjust the size of the cardboard one person operation, easy and fast.

9.Imported rubber wheel, long service life.

10.Low noise, easy maintenance, high economic efficiency.

11.Better adapt to a variety of cardboard, and the paper feed is stable and accurate.

Function introduction:

Man-machine interface - PLC control, the system for the robot operating system, more humane, fast setting, a few seconds to change the order, greatly shorten the waste of machine time.

1.This machine can support manual, (scattered order) automatic (large order) two modes of one-click switching.

2.Paper cutter, prepress wheel, press wheel automatically adjust independently.

3.One key switch with left and right hand operation, thickness 1.5~15mm (E flute to 7 layers 3A).

4.3 layers, 5 layers, 7 layers of cardboard one key to confirm, automatic gap adjustment.

5.In the automatic order mode of the operating system, it can be connected to the ERP of the raw management system, support the function of scanning code order, non-stop order adjustment, easier operation, error-free, and can produce thousands of orders every day.

6.Manual/automatic knife sharpening.

7.The machine adopts the train heavy rail as the supporting slipway of moving knife base and line base, which is stable and smooth.

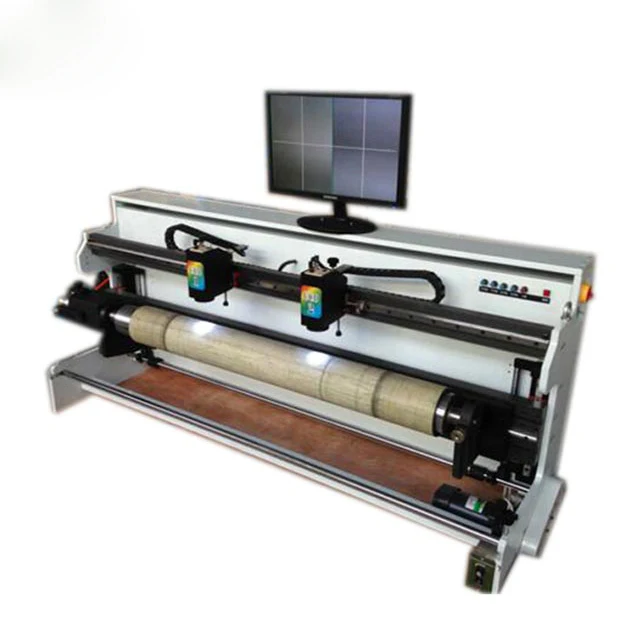

8.Front and rear cameras, fast and safe.

9.The minimum slitting width between the knife and the knife is 130mm, the shortest paper feed is 180mm.

10.Leading edge suction paper feed, accurate counting.

11.Click and fine-tune.

12.Intelligent graphics operating system, popular, easy to understand, ordinary workers can operate.

13.Customize the knife and line distance.

14.Automatic counting.

15.Paper slitting and line pressing accuracy ±0.5mm.

1.Man-machine interface - PLC control, cutting cardboard, ordering are independent stepper motor control, automatic scheduling order speed 1-10 seconds, error accuracy ±0.5 mm.

2.The operation is very humanized, high-tech, ordinary workers can operate.

3.Slitting part: Using high-quality tungsten steel alloy blade, long service life, slitting out the cardboard incision neatly without fracturing, no burrs.

4.Both sides of the thin slitter scorer machine use rubber wheels to press cardboard to overcome the phenomenon of no pressure line, deviation and poor straightness when cutting the board alone.

5.The knife sharpening device adopts automatic and manual pneumatic knife sharpening methods, which can work while sharpening the knife and improve the work efficiency.

6.Electrical appliances are made of domestic brands or imported products with reliable performance.

7.This machine can store 999 groups of orders, to achieve non-stop order change and manual order change.

8.With automatic paper feed table to adjust the size of the cardboard one person operation, easy and fast.

9.Imported rubber wheel, long service life.

10.Low noise, easy maintenance, high economic efficiency.

11.Better adapt to a variety of cardboard, and the paper feed is stable and accurate.

Function introduction:

Man-machine interface - PLC control, the system for the robot operating system, more humane, fast setting, a few seconds to change the order, greatly shorten the waste of machine time.

1.This machine can support manual, (scattered order) automatic (large order) two modes of one-click switching.

2.Paper cutter, prepress wheel, press wheel automatically adjust independently.

3.One key switch with left and right hand operation, thickness 1.5~15mm (E flute to 7 layers 3A).

4.3 layers, 5 layers, 7 layers of cardboard one key to confirm, automatic gap adjustment.

5.In the automatic order mode of the operating system, it can be connected to the ERP of the raw management system, support the function of scanning code order, non-stop order adjustment, easier operation, error-free, and can produce thousands of orders every day.

6.Manual/automatic knife sharpening.

7.The machine adopts the train heavy rail as the supporting slipway of moving knife base and line base, which is stable and smooth.

8.Front and rear cameras, fast and safe.

9.The minimum slitting width between the knife and the knife is 130mm, the shortest paper feed is 180mm.

10.Leading edge suction paper feed, accurate counting.

11.Click and fine-tune.

12.Intelligent graphics operating system, popular, easy to understand, ordinary workers can operate.

13.Customize the knife and line distance.

14.Automatic counting.

15.Paper slitting and line pressing accuracy ±0.5mm.

Can be equipped with automatic stacker

1.Manual, automatic, longboard mode.

2.Servo paper receiving, stacking part automatic division, fit, easy to operate, pat the board function.

3.Computer knife adjustment, one key switch.

4.The positive and negative error of the size is less than 2 mm, and the four angles are 90 degrees.

5.With pre-set count, dispatch function. The stacking part is automatically lifted and lowered, which can butt the board height of the whole machine.

6.The fiber comb is used to press the cut cardboard, so that the cardboard is neat and reaches the predetermined amount, and it is automatically transported to the rear of the operating table by belt.

7.The number of pieces and belt rotation can be set in automatic mode.

8.The total height of the lifting plate is 800, and the lifting plate is 400.

9.Lift the board over 2500 paper.

10.Overall dimensions 2460×3300×1700.

1.Manual, automatic, longboard mode.

2.Servo paper receiving, stacking part automatic division, fit, easy to operate, pat the board function.

3.Computer knife adjustment, one key switch.

4.The positive and negative error of the size is less than 2 mm, and the four angles are 90 degrees.

5.With pre-set count, dispatch function. The stacking part is automatically lifted and lowered, which can butt the board height of the whole machine.

6.The fiber comb is used to press the cut cardboard, so that the cardboard is neat and reaches the predetermined amount, and it is automatically transported to the rear of the operating table by belt.

7.The number of pieces and belt rotation can be set in automatic mode.

8.The total height of the lifting plate is 800, and the lifting plate is 400.

9.Lift the board over 2500 paper.

10.Overall dimensions 2460×3300×1700.

No. | Model | CZXY 2750 | CZXY 3000 | CZXY 3250 |

1 | Knives and creasing | 4 knives and 6 lines | 4 knives and 6 lines | 4 knives and 6 lines |

2 | Max.production speed | 180m/min | 180m/min | 180m/min |

3 | Widest feeding size | 2500mm | 2750mm | 3000mm |

4 | Max.slitting width | 2100mm | 2350mm | 2600mm |

5 | Min.slitting width | 130mm | 130mm | 130mm |

6 | Min.feeding length | 180mm | 200mm | 200mm |

7 | Min.creasing distance | 35mm×100mm | 35mm×100mm | 35mm×100mm |

8 | Gap adjustment | automatic | automatic | automatic |

9 | Main motor power | 5.5-6KW | 5.5-6KW | 5.5-6KW |

10 | Dimension (L*W*H) | 3800*1000*1700mm | 4350*1800*1850mm | 4850*1800*1850mm |

11 | Overall weight | 2880kg | 3200kg | 3500kg |

We Recommend

New Arrivals

New products from manufacturers at wholesale prices