hot dip galvanized iron steel coil metallic material steel coils sheet

- Category: >>>

- Supplier: Langfang Weikaihua Building Material Co. Ltd.Langfang Ltd.

Share on (1601292191725):

Product Overview

Description

Product Description

Product Name | galvanized steel coil |

Thickness | 0.12-6.0mm |

Width | 600-1500 mm |

Tolerance | ±0.02mm |

Zinc coating | 40-600g/m2 |

Hardness | Soft hard(HRB60),medium hard(HRB60-85),full hard(HRB85-95) |

Surface Structure | Normal spangle coating(NS), minimized spangle coating(MS), spangle-free(FS) |

Surface Treatment | Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U) |

Coil ID | 508mm/610mm/customized |

Coil Weight | 3-8 tons/customized |

Technique | Hot rolled, cold rolled |

Package | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve |

Certification | ISO 9001-2008,SGS,CE,BV |

MOQ | 22 TONS (in one 20ft FCL) |

Delivery | 15-20 days |

Monthly Output | 30000 tons |

Description | Galvanized steel is mild steel with a coating of zinc. The zinc protects the steel by providing cathodic protection to the exposed steel, so should the surface be damaged the zinc will corrode in preference to the steel. Zinc steel is one of the most widely used products, used extensively in the building sector, automotive, agricultural and other areas where the steel needs to be protected from corrosion |

Payment | T/T, LC, Kun Lun Bank,Western Union, Paypal |

Product Introduction

Hot-dip galvanizing is the reaction of molten metal with an iron substrate to produce an alloy layer, thereby combining the substrate and the plating layer. Hot-dip galvanizing is to pickle iron and steel parts first. In order to remove iron oxide on the surface of iron and steel parts, after pickling, it is cleaned in an ammonium chloride or zinc chloride aqueous solution or a mixed solution of ammonium chloride and zinc chloride.And then sent to the hot-dip plating bath. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life.

Product Advantages

1.Anti-corrosive : 20 years in heavy industrial area and 30 years in cities.

2.Cheap : The cost of hot-dip galvanizing is lower than that of other coatings.

3.Reliable : The zinc coating is metallurgically bonded to the steel and forms part of the steel surface,so the coating is more durable.

4.Strong toughness : The galvanized layer forms a special metallurgical structure that can withstand mechanical damage during transportation and use.

5.Comprehensive protection : Every part of the plated piece can be galvanized,and is fully protected even in depressions,sharp corners,and hidden places.

06.Save time and energy : Galvanizing process is faster than other coating methods.

2.Cheap : The cost of hot-dip galvanizing is lower than that of other coatings.

3.Reliable : The zinc coating is metallurgically bonded to the steel and forms part of the steel surface,so the coating is more durable.

4.Strong toughness : The galvanized layer forms a special metallurgical structure that can withstand mechanical damage during transportation and use.

5.Comprehensive protection : Every part of the plated piece can be galvanized,and is fully protected even in depressions,sharp corners,and hidden places.

06.Save time and energy : Galvanizing process is faster than other coating methods.

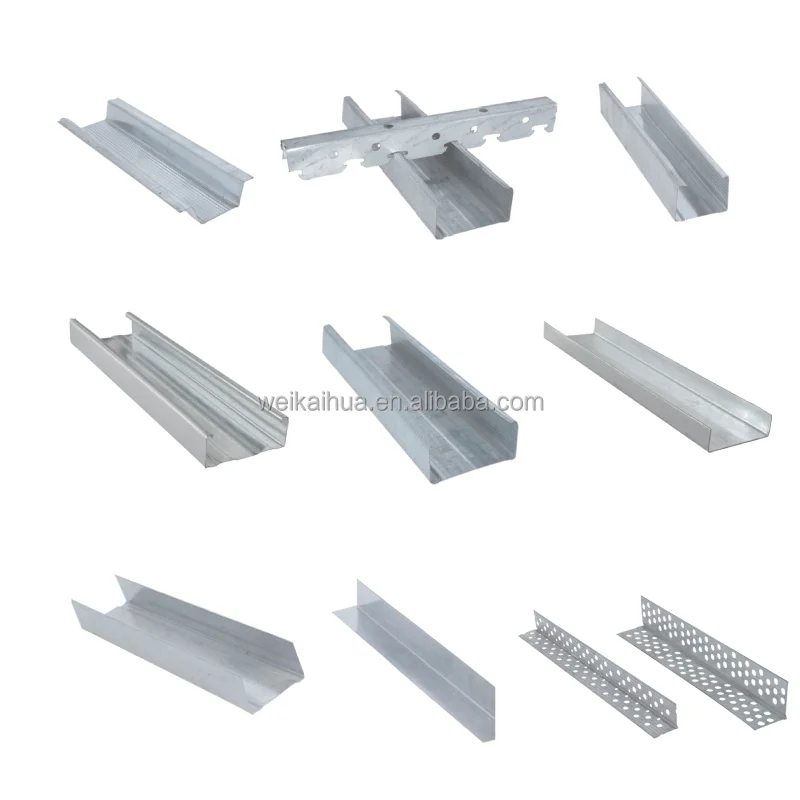

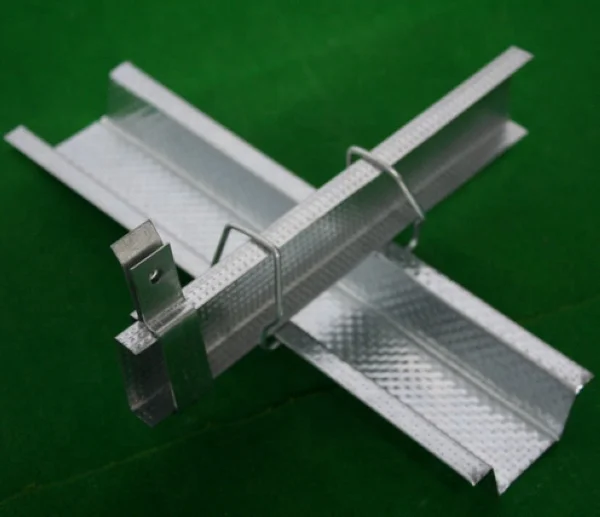

Detailed Images

Production Line

STORAGE&TRANSPORT

VR Museum

Certificate

Company Introduction

Our Services & Strength

1. Company Development

WBM has been conducting the ceiling grid manufacturing business since 1996, with more than 20 years of elaborate production and management experiences.

In 2003, WBM has been transformed from a small factory to a modern manufacturing enterprise.and started our international business in 2005,

At the beginning of 2007, the Export Department was formally established, and our sales network is further extended to the global market.

2. Research Team

Never forget the original intention so that we can get the result we want in the end,but it was easy to have an initiative and

difficult holding on to it.

However, WBM has been constantly insisting on the improvement of production and research

for more than 20 years, we accumulated the experiences of several generations of technicians, overcame numerous technical difficulties, and, consequently, each elaborately made product has stood the test of the global market, and has received good reputation from collaborated clients world-widely.

WBM factory management standards had passed the ISO international management system certification, and all our products had passed the most stringent SGS and CE global quality certifications.

3. Company Scale

WBM factory covers an area of 50,000 square meters, and is still in the process of expansion.

Our factory is equipped with nearly 100 production lines.

Thanks to the automation improvement, the number of operators has been greatly reduced and the process were further optimized, and

the size of technical teams were expanded.

Thus, in 2018, the total production amount has reached 30,000,000 square meters.

4. Products Positioning

Our products has covered the vast majority of global market varieties and specifications, besides, we can provide customized products according to our customers’ requirements.

WBM products positioning has always been aiming at the middle and high-end markets, and our most advantageous categories were selected for self-brand promotion.

We guarantee premium quality for our global users with our 20-plus years of profession, dedication, and ingenuity experiences in the ceiling grid industry.

WBM has been conducting the ceiling grid manufacturing business since 1996, with more than 20 years of elaborate production and management experiences.

In 2003, WBM has been transformed from a small factory to a modern manufacturing enterprise.and started our international business in 2005,

At the beginning of 2007, the Export Department was formally established, and our sales network is further extended to the global market.

2. Research Team

Never forget the original intention so that we can get the result we want in the end,but it was easy to have an initiative and

difficult holding on to it.

However, WBM has been constantly insisting on the improvement of production and research

for more than 20 years, we accumulated the experiences of several generations of technicians, overcame numerous technical difficulties, and, consequently, each elaborately made product has stood the test of the global market, and has received good reputation from collaborated clients world-widely.

WBM factory management standards had passed the ISO international management system certification, and all our products had passed the most stringent SGS and CE global quality certifications.

3. Company Scale

WBM factory covers an area of 50,000 square meters, and is still in the process of expansion.

Our factory is equipped with nearly 100 production lines.

Thanks to the automation improvement, the number of operators has been greatly reduced and the process were further optimized, and

the size of technical teams were expanded.

Thus, in 2018, the total production amount has reached 30,000,000 square meters.

4. Products Positioning

Our products has covered the vast majority of global market varieties and specifications, besides, we can provide customized products according to our customers’ requirements.

WBM products positioning has always been aiming at the middle and high-end markets, and our most advantageous categories were selected for self-brand promotion.

We guarantee premium quality for our global users with our 20-plus years of profession, dedication, and ingenuity experiences in the ceiling grid industry.

FAQ

Q:Are you a manufacture ort trade company ?

we are manufacture with our own export company .

-about 17years production experience.

Q: How long is your production time ?

10-15 working days after receiving deposit.

Q:What is the shipping way?

by sea to your nearest seaport.

Q:What kinds of steel channel you can provide ?

T24/T15 Flat surface ceiling grid. Ultraline and Flat Ultraline systems. Groove system and Wall angles etc

Q;Could you offer samples ?

yes.we could offer samples,but not undertake the experess cost .

Q:Is it possible to customization for special size ?

Yes,support tp prouduce the special size if bulk order.

we are manufacture with our own export company .

-about 17years production experience.

Q: How long is your production time ?

10-15 working days after receiving deposit.

Q:What is the shipping way?

by sea to your nearest seaport.

Q:What kinds of steel channel you can provide ?

T24/T15 Flat surface ceiling grid. Ultraline and Flat Ultraline systems. Groove system and Wall angles etc

Q;Could you offer samples ?

yes.we could offer samples,but not undertake the experess cost .

Q:Is it possible to customization for special size ?

Yes,support tp prouduce the special size if bulk order.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices