Wholesale Best Seller Iron Soft Sealed Unidirectional Pneumatic Knife Gate Valve For Slurry Soft Valved Seal

- Category: >>>

- Supplier: Zhangguo Industry Co. Ltd.Zhangguo Ltd.

Share on (1601292676717):

Product Overview

Description

Products Description

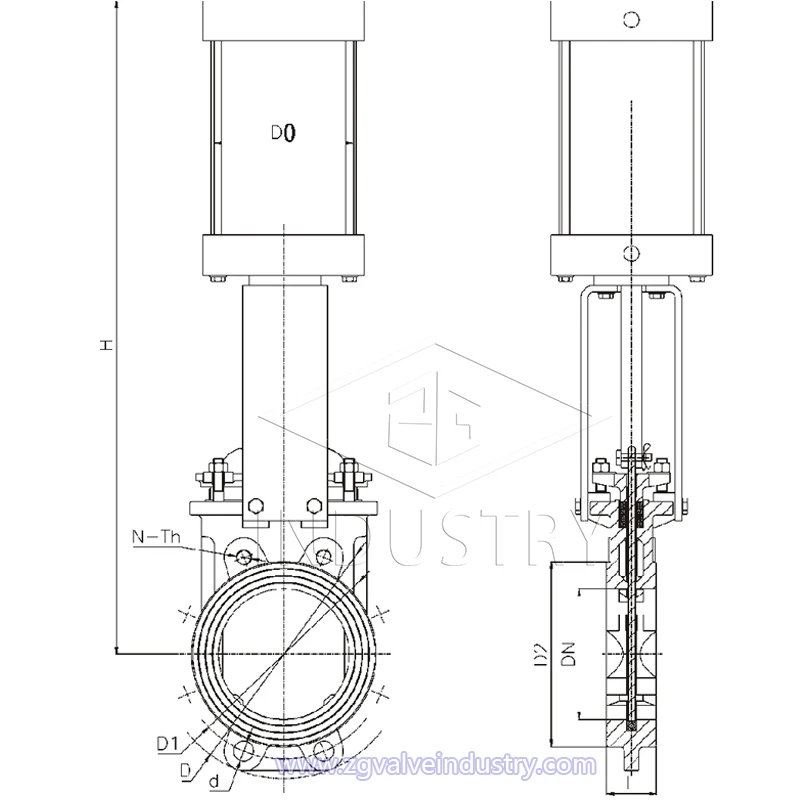

Pneumatic Knife Gate Valve

ZG Pneumatic Knife Gate Valve (DN50-DN3200), pressure (PN6~PN63, class150~class900), material (WCB, stainless steel, Hard alloy) 100% pressure test, 10 inspection procedures, CE Pressure equipment certification.

Size Range: 1 1/2“-48”/DN40-DN1200Seat Materials: EPDM/NBR

Pressure: PN10/PN16

Body Materials: HT200/QT450

Disc Materials: 2Cr13/201/304/316/316L

Stem Materials: 2Cr13/304/316/316L

Payment: T/T, D/P or L/C

Lead Time: 5-30 days

Description

the gate. The movement direction of the gate of the knife gate valve is perpendicular to the direction of the fluid, and the

medium is cut by a blade-shaped gate that can cut fiber materials. Knife gate valve, with its advantages of small size, small flow resistance, light weight, easy installation, easy disassembly, etc., completely solves the large flow resistance, heavy weight, etc. of ordinary gate valves, flat gate valves, ball valves, globe valves, regulating valves, butterfly valves, etc. Difficult problems such as difficult installation and large area. After the emergence of knife gate valves, a large number of general shut-off valves and regulating valves have been replaced. The knife gate valve has a small installation space, low working pressure, is not easy to accumulate debris, and the price is low. When the knife gate valve is closed, the sealing surface can only rely on the medium pressure to seal, that is, rely on the medium pressure to press the sealing surface of the gate against the valve seat on the other side to ensure the sealing of the sealing surface. This is self-sealing. Most gate valves are Forced sealing is adopted, that is, when the valve is closed, the gate must be forced to the valve seat by external force to ensure the tightness of the sealing surface. This type of valve should generally be installed vertically in the pipeline.

The scope of application of knife gate valve is:

Design Features:

Knife gate valve is also called knife gate valve, knife gate valve, slurry valve, mud valve, and its opening and closing part is

the gate. The movement direction of the gate of the knife gate valve is perpendicular to the direction of the fluid, and the

medium is cut by a blade-shaped gate that can cut fiber materials. Knife gate valve, with its advantages of small size, small flow resistance, light weight, easy installation, easy disassembly, etc., completely solves the large flow resistance, heavy weight, etc. of ordinary gate valves, flat gate valves, ball valves, globe valves, regulating valves, butterfly valves, etc. Difficult problems such as difficult installation and large area. After the emergence of knife gate valves, a large number of general shut-off valves and regulating valves have been replaced. The knife gate valve has a small installation space, low working pressure, is not easy to accumulate debris, and the price is low. When the knife gate valve is closed, the sealing surface can only rely on the medium pressure to seal, that is, rely on the medium pressure to press the sealing surface of the gate against the valve seat on the other side to ensure the sealing of the sealing surface. This is self-sealing. Most gate valves are Forced sealing is adopted, that is, when the valve is closed, the gate must be forced to the valve seat by external force to ensure the tightness of the sealing surface. This type of valve should generally be installed vertically in the pipeline.

Field of Application:

Size Range: 1 1/2"-48"/DN40-DN1200

Temperature: (-)29℃ to (+) 120℃

Allowable Operating Pressure:PN10/PN16

1. Mining, coal washing, iron and steel industry-used for coal washing pipelines, filter slurry pipelines, etc., ash discharge

pipelines;

pipelines;

2. Purification device-used for waste water, mud, dirt and clarified water with suspended matter;

3. Paper industry-used for any consistency of pulp, material and water mixture;

4. Deashing of power station-used for ash slurry.

Performance Specifications:

Nomial PressurePN10PN16Nomial Pressure1.0Mpa1.6MpaIntensity Test1.5Mpa2.4MpaBack Seal1.1Mpa1.76MpaSeal Test1.1Mpa1.76MpaGas Test 0.6Mpa0.6MpaWorking Temperature-29℃ ~ 120℃MediumPulp, mud, sewage, powder, various liquid fluids

Technical Specification:

End Flange Dimension GB/T9113.1

MATERIAL LIST | ||

Part Name | Specification | |

Body | HT200,QT450 | |

Disc | 2Cr13,201,304,316,316L | |

Stem | 2Cr13,304,316,316L | |

Seat | EPD,NBR | |

Packing | PTFE packing,Graphite packing | |

Ste Nut | Cast aluinu brass | |

Handwheel | alleable iron | |

Standard Accessory | A3,stainless steel | |

Size | L mm | DN | Cylinderstroke | L | H | ||

DN mm | Inch | ||||||

50 | 2" | 108 | 50 | 65 | 48 | 590 | |

65 | 22/1" | 112 | 65 | 80 | 48 | 610 | |

80 | 3" | 114 | 80 | 100 | 51 | 650 | |

100 | 4" | 127 | 100 | 120 | 51 | 705 | |

125 | 5" | 140 | 125 | 145 | 57 | 750 | |

150 | 6" | 140 | 150 | 170 | 57 | 810 | |

200 | 8" | 152 | 200 | 220 | 60 | 930 | |

250 | 10" | 165 | 250 | 270 | 70 | 1080 | |

300 | 12" | 178 | 300 | 330 | 76 | 1140 | |

350 | 14" | 190 | 350 | 380 | 76 | 1290 | |

400 | 16" | 216 | 400 | 430 | 89 | 1344 | |

450 | 18" | 222 | 450 | 480 | 89 | 1555 | |

500 | 20" | 229 | 500 | 530 | 114 | 1606 | |

600 | 24" | 267 | 600 | 630 | 114 | 1806 | |

700 | 28" | 292 | 700 | 730 | 117 | 2090 | |

800 | 32" | 318 | 800 | 830 | 117 | 2320 | |

We Recommend

New Arrivals

New products from manufacturers at wholesale prices