OEM/ODM metallurgy Manual DIN DN150 DN300 PN16 Bellows Seal Stem Extension Spindle Gate Valve for water treatment

- Category: >>>

- Supplier: Zhangguo Industry Co. Ltd.Zhangguo Ltd.

Share on (1601295072377):

Product Overview

Description

DIN Bellows Seal Gate Valve

ZG VALVE DIN Bellows Seal Gate Valve(DN15-DN3000), CE pressure equipment Certification,10 inspection procedures, multiple pressure tests,two-year warranty, a variety of materials are available.

Size Range: 1 1/2“-12”/DN40-DN300

Size Range: 1 1/2“-12”/DN40-DN300

Pressure: PN16/PN25/PN40

Body Materials: GG/GS-C25/CF8/CF8M

Disc Materials: GS-C25/CF8/CF8M

Stem Materials: 13Cr/SS304/SS316

Packing Materials: Flexible Graphite

Payment: T/T, D/P or L/C

Lead Time: 5-30 days

Description

Design Features:

1、Meet the requirements of advanced standards, reliable sealing, excellent performance and beautiful appearance.

2、The sealing matching is advanced and reasonable. The sealing surface of the gate and the valve seat is made of hard alloy with different hardness. The sealing is reliable, high hardness, wear resistance, high temperature resistance, corrosion resistance, good scratch resistance and long life.

2、The sealing matching is advanced and reasonable. The sealing surface of the gate and the valve seat is made of hard alloy with different hardness. The sealing is reliable, high hardness, wear resistance, high temperature resistance, corrosion resistance, good scratch resistance and long life.

3、After quenching and tempering and surface nitriding treatment, the valve stem has good

corrosion resistance, scratch resistance and wear resistance.

corrosion resistance, scratch resistance and wear resistance.

4、Various piping flange standards and flange sealing surface forms can be used to meet various engineering needs and user requirements.

ZG valve has obvious advantages such as light switch, reliable sealing, good elastic memory and service life.

Field of Application:

Size Range: DN40 and DN300

Temperature: (-)29℃ to 425℃

Allowable Operating Pressure:PN16、PN25、PN40

Gate valve is widely used in petrochemical plants, metallurgy, water treatment, thermal power plants and other oil and water vapor pipelines to connect or cut off the medium in the pipeline.

Performance Specifications:

Nomial PressurePN16PN25PN40Nomial Pressure1.6Mpa 2.5Mpa4.0MpaIntensity Test2.4Mpa3.75Mp6.0MpaBack Seal1.76Mpa2.75Mp4.4MpaSeal Test 1.76Mpa2.75Mp4.4MpaGas Test0.6Mpa0.6Mpa0.6MpaWorking Temperature-29℃ ~ 425℃MediumW.O.G

Technical Specification:

1. Design Standard DIN EN12288-2003

2. Face to Face Dimension DIN EN588-1:1995

3. End Flange Dimension

DIN EN1092-1:2002

DIN EN1092-1:2002

4. Test Standard DIN EN12266:2003

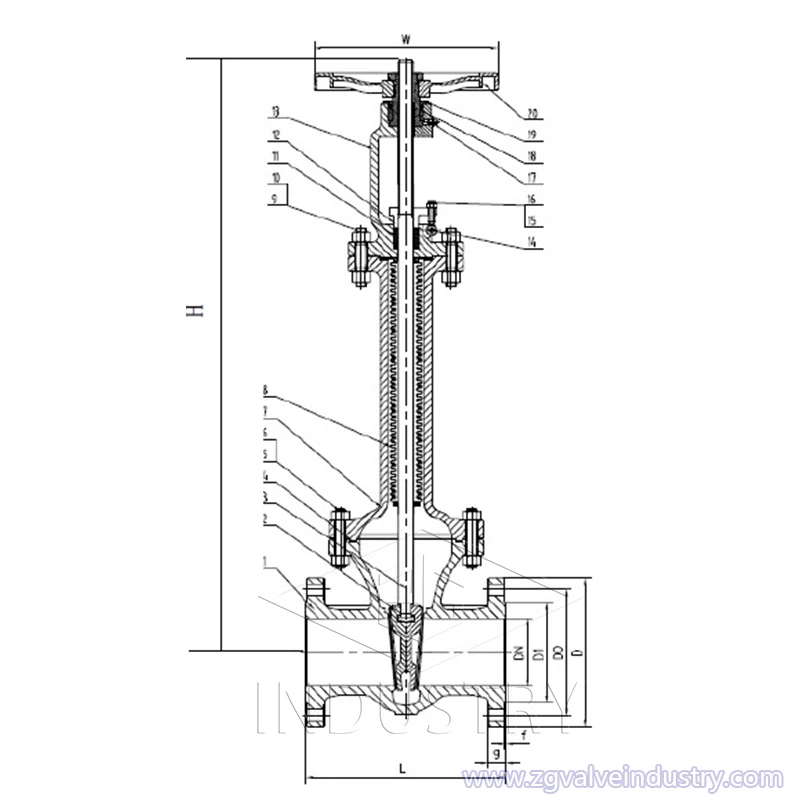

Item No. | Part Name | Specification |

1 | Body | GG GS-C25, CF8, CF8M |

2 | Disc | GS-C25, CF8, CF8M |

3 | Stem | 13Cr, F304, F316 |

4 | Gasket | Flexible Graphite+304 |

5 | Bolt | A193-B7, A193-B8 |

6 | Nut | A1942H, A194-8 |

7 | Bonnet | GG GS-C25, CF8, CF8M |

8 | Bellows | 304, 304, 316 |

9 | Bolt | A193-B7, A193-B8 |

10 | Nut | A1942H, A194-8 |

11 | Packing | Flexible Graphite |

12 | Gland | GS-C25. SS304 SS316 |

13 | Yoke | GS-C25,304,316 |

14 | Keybolt | A193-B7, B8 |

15 | Nut | A1942H, A194-8 |

16 | Pin | 35, 304, 316 |

17 | Oil Cup | ------------ |

18 | Stem Nut | H62 |

DN | PN16 | ||||||||||||||||

L | D | D0 | D1 | g | f | nXd | H | W | |||||||||

40 | 140 | 150 | 110 | 88 | 18 | 3 | 4x18 | 405 | 200 | ||||||||

50 | 150 | 165 | 125 | 102 | 18 | 3 | 4x18 | 455 | 200 | ||||||||

65 | 170 | 185 | 145 | 122 | 18 | 3 | 8x18 | 593 | 200 | ||||||||

80 | 180 | 200 | 160 | 138 | 20 | 3 | 8x18 | 695 | 200 | ||||||||

100 | 190 | 220 | 180 | 158 | 20 | 3 | 8x18 | 830 | 200 | ||||||||

125 | 200 | 250 | 210 | 188 | 22 | 3 | 8x18 | 950 | 250 | ||||||||

150 | 210 | 285 | 240 | 212 | 22 | 3 | 8x22 | 1123 | 250 | ||||||||

200 | 230 | 340 | 295 | 268 | 24 | 3 | 12x22 | 1465 | 300 | ||||||||

250 | 250 | 405 | 355 | 320 | 26 | 3 | 12x26 | 1790 | 350 | ||||||||

300 | 270 | 460 | 410 | 378 | 28 | 4 | 12x26 | 2140 | 400 | ||||||||

We Recommend

New Arrivals

New products from manufacturers at wholesale prices