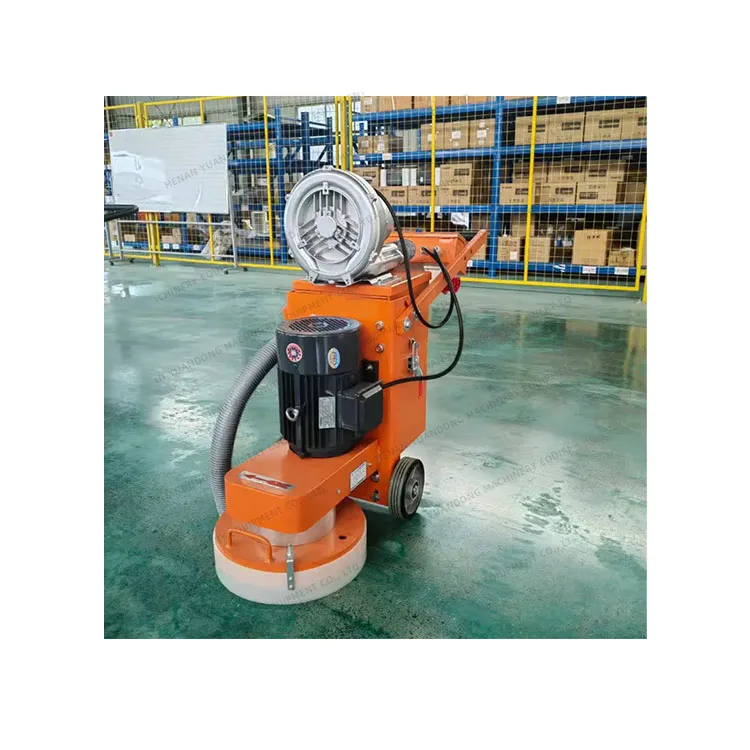

Hot Selling Multifunctional Floor Tile Grinding Machine Good Price Walk Behind Marble Grinding Machine

- Category: >>>

- Supplier: SWANTECH INDUSTRY PTE LTDSWANTECH LTD

Share on (1601295331493):

Product Overview

Description

Specification

1. There are four plates, and every plate can install three diamond grinding discs. When four plates are revolving, diamond grinding discs are revolving at the same time, and grinding is more evenly, so that scratch sweep away.

2. High-quality lithium-ion battery drive can keep work for more than 100km without charge. Cruising at a constant speed, different workers achieve the same grinding effect.

3. Large grinding diameter, 80 cm chassis, grinding efficiency three times.

4. Pure copper motor, strong power, all-aluminum alloy gearbox, strong and durable.

5. 60L aluminum alloy large water tank can achieve dry grinding and wet grinding.

2. High-quality lithium-ion battery drive can keep work for more than 100km without charge. Cruising at a constant speed, different workers achieve the same grinding effect.

3. Large grinding diameter, 80 cm chassis, grinding efficiency three times.

4. Pure copper motor, strong power, all-aluminum alloy gearbox, strong and durable.

5. 60L aluminum alloy large water tank can achieve dry grinding and wet grinding.

Model | YMG-800 |

Inverter | 18.5kw |

Motor power | 15KW |

Walking power | 800W |

Voltage | 380V |

Working width | 800mm |

Motor speed | 0-1800r/min |

Headcount | 12PCS |

Ash bucket capacity | 60L |

Balancing weight | 50kg |

Weight | 532KGS |

Product Description

How to choose the blade of the floor grinder?

Resin grinding disc: Suitable for high-strength concrete floor, granite, Stone renovation, and so on. Dry grinding, strong cutting force, saving labor and working hours.

Diamond grinding disc: Suitable for leveling concave and convex concrete floors.

All 5 types of blades are capable of both dry and wet grinding.

Grinding, polishing, cleaning, and other construction requirements can be met.

It can be equipped with different types of grinding discs and blades, the needs of epoxy floors, cement floors, diamonds, etc.

Resin grinding disc: Suitable for high-strength concrete floor, granite, Stone renovation, and so on. Dry grinding, strong cutting force, saving labor and working hours.

Diamond grinding disc: Suitable for leveling concave and convex concrete floors.

All 5 types of blades are capable of both dry and wet grinding.

Grinding, polishing, cleaning, and other construction requirements can be met.

It can be equipped with different types of grinding discs and blades, the needs of epoxy floors, cement floors, diamonds, etc.

How to use a floor grinder?

Turn up the machine, clean up the three-blade pan, put the rotary vane disc equip the head of three blades,

Put down the machine to the working site.

Connect the power with the explosion-proof plug, (must use international standard cable conductor equal to or more than 4²), turn on the red start button, red power LED lights up.

Press the green start button, frequency charger starts working.

Rotate the speed switch, the motor starts working, the machine starts normal work.

After finishing working, turn down the speed switch to the minimum value, Press the red stop button after the machine completely finished working, then close the power (attention: Red stop button is allowed when an emergency.)

Turn up the machine, clean up the three-blade pan, put the rotary vane disc equip the head of three blades,

Put down the machine to the working site.

Connect the power with the explosion-proof plug, (must use international standard cable conductor equal to or more than 4²), turn on the red start button, red power LED lights up.

Press the green start button, frequency charger starts working.

Rotate the speed switch, the motor starts working, the machine starts normal work.

After finishing working, turn down the speed switch to the minimum value, Press the red stop button after the machine completely finished working, then close the power (attention: Red stop button is allowed when an emergency.)

Packing & Delivery

Exporting package

1 unit was packed into an iron frame and then packed with 5 layers of corrugated carton. 4 strips reinforced the carton. the fix package guaranteed the machines were not damaged during transportation

Company Profile

SWANTECH INDUSTRY PTE. LTD.:

Your Global Construction Solutions Partner

Established in 2015 under the "SWANTECH" brand, we've exported nearly 10,000 machines worldwide. Headquartered in Singapore with a branch in China, SWANTECH offers global expertise with personalized service.

Specializing in concrete and mid-range construction machinery, we're committed to providing tailored solutions that match our customers' needs. From concrete mixers, concrete batching plants, concrete trucks, to concrete pumps, and construction machinery our range covers diverse construction requirements.

At SWANTECH, Our commitment to integrity and expertise ensures that clients receive honest answers and optimal recommendations for their construction needs. With a focus on customer satisfaction, we offering expert advice and precise solutions, whether they're completing ongoing projects or venturing into new businesses globally.

FAQ

Q1. What can we do if there are problems with the products?

A: Our engineers will analyze the problem for you and find the best solution. If problems happened within the guaranteed time, we can replace the components for you free of charge. We have dealers in some countries, for some technical problems which you can not solve by yourself.

Q2. What is the delivery time for your products?

A: Once we promise the delivery time, we will try our best to fulfill it. Special procedures such as emergency inventory will be used to maintain your uninterrupted supply of the products.

Q3. Is there any guarantee for your products?

A: Most of our products have one year guarantee(for the main parts).

Q4. How can you control your product quality?

A: Quality is always considered the most important part of our manufacturing process. All of our products come under a strict quality control system from raw material inspection, component inspecting,semi-finished product inspecting, and performance test of finished products, to random inspection before delivery.

A: Our engineers will analyze the problem for you and find the best solution. If problems happened within the guaranteed time, we can replace the components for you free of charge. We have dealers in some countries, for some technical problems which you can not solve by yourself.

Q2. What is the delivery time for your products?

A: Once we promise the delivery time, we will try our best to fulfill it. Special procedures such as emergency inventory will be used to maintain your uninterrupted supply of the products.

Q3. Is there any guarantee for your products?

A: Most of our products have one year guarantee(for the main parts).

Q4. How can you control your product quality?

A: Quality is always considered the most important part of our manufacturing process. All of our products come under a strict quality control system from raw material inspection, component inspecting,semi-finished product inspecting, and performance test of finished products, to random inspection before delivery.

We Recommend

20 Inch High Speed Terrazzo Marble Floor Polishing Machine

$1,000.00-1,500.00

RONLON Hot Selling Concrete Floor Polishing Machine Floor Polisher Equipment

$1,720.00-1,850.00

New Arrivals

New products from manufacturers at wholesale prices