Pure Ceramic Foam Filter For Titanium Casting High Purity Material Meet Stringent Quality Standards

- Category: >>>

- Supplier: Gongyi City Tonten Abrasive Co. Ltd.Gongyi Ltd.

Share on (1601295476416):

Product Overview

Description

Products Description

Pure Ceramic Foam Filter For Titanium Casting High Purity Material Meet Stringent Quality Standards

-- -- FOUR ADVANTAGES -- --

1. Filter out the inclusions in the casting, reduce the gas in the casting, reduce the turbulence degree of liquid metal flow during filling, reduce the surface defects in the casting, and significantly reduce the scrap rate of the casting;2. Increase the compressive tightness, elongation and tensile strength of the casting, improve the surface finish of the casting, improve the fluidity of molten metal, and increase the mold filling capacity and feeding capacity of the casting;

3. It has very high high working strength at high temperature, chemical stability, thermal shock resistance and metal flow impact resistance. There is no slag falling or cracking in the work, which ensures the stability of the chemical composition of the filtering quality of molten metal;

4. The machining time and tool damage are reduced, and the machined surface quality of castings is improved. It has high chemical stability, is not affected by the acidity and alkalinity of the molten metal, and does not change the chemical composition of the molten metal.

Product Information

Pure Ceramic Foam Filter For Titanium Casting High Purity Material Meet Stringent Quality Standards

The hot metal filter is made of high silica glass fiber mesh coated with a unique formula of refractory materials, which can effectively remove non-metallic impurities in molten metal, reduce turbulence, eliminate air holes in castings, and significantly reduce the rate of casting scrap. The hot metal filter is easy to use and economical.

Product specification: conventional mesh is 1.5 * 1.5mm, 2.0 * 2.0mm, 2.5 * 2.5mm. It can be prefabricated into flat sheets and molded special-shaped products of different sizes and shapes according to the needs of users.

Product specification: conventional mesh is 1.5 * 1.5mm, 2.0 * 2.0mm, 2.5 * 2.5mm. It can be prefabricated into flat sheets and molded special-shaped products of different sizes and shapes according to the needs of users.

Type | NX-HSFG |

Work temperature | ≤1620/1450(℃) |

Softening temperature | 1700(℃) |

Gas emit | ≤60cm³/g |

Thickness | 1.5/0.5mm |

Hole size | 1.5*1.5mm/2.0*2.0mm/2.5*2.5mm |

Weave patterm | Mock Leno / Leno |

The filter can be placed at any position of the casting system, as close to the casting as possible, to minimize the scouring force of molten metal. In case of in-mold inoculation or in-mold spheroidization, the filter should be placed behind the reaction chamber, and the filter should be as close to the ingate as possible.

More Details

Pure Ceramic Foam Filter For Titanium Casting High Purity Material Meet Stringent Quality Standards

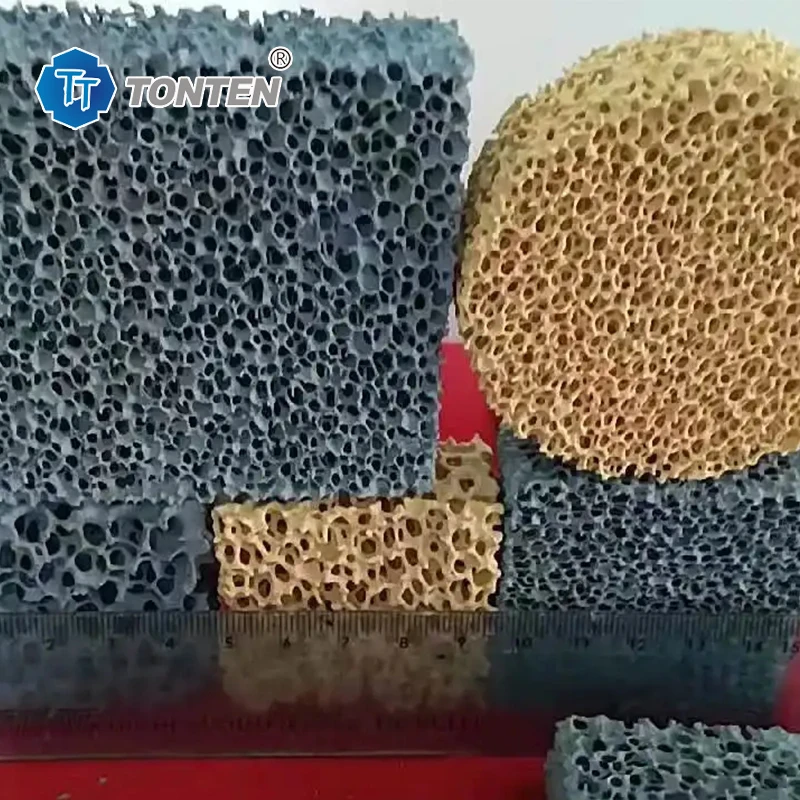

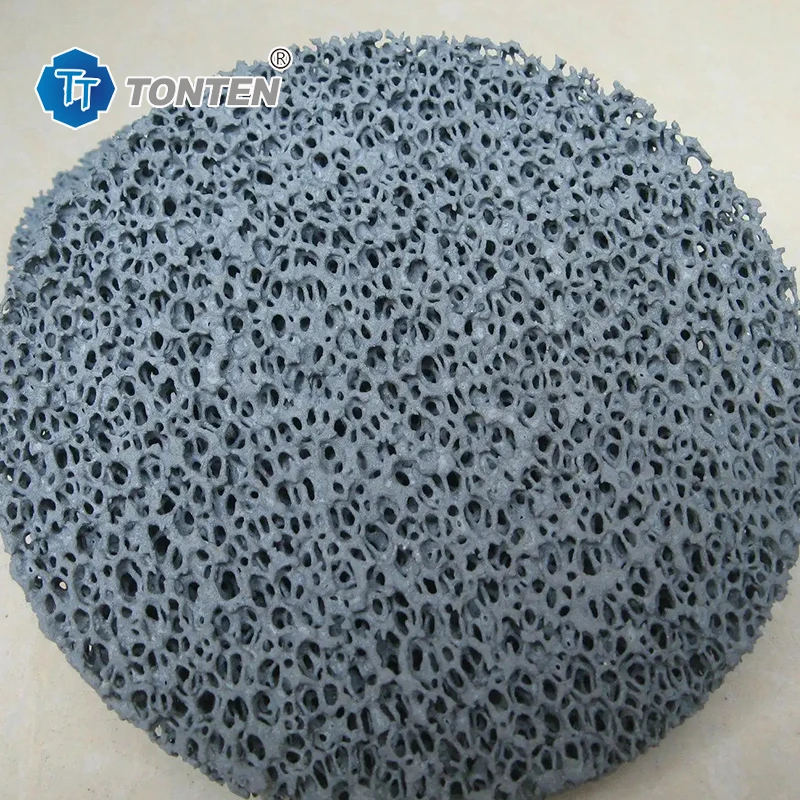

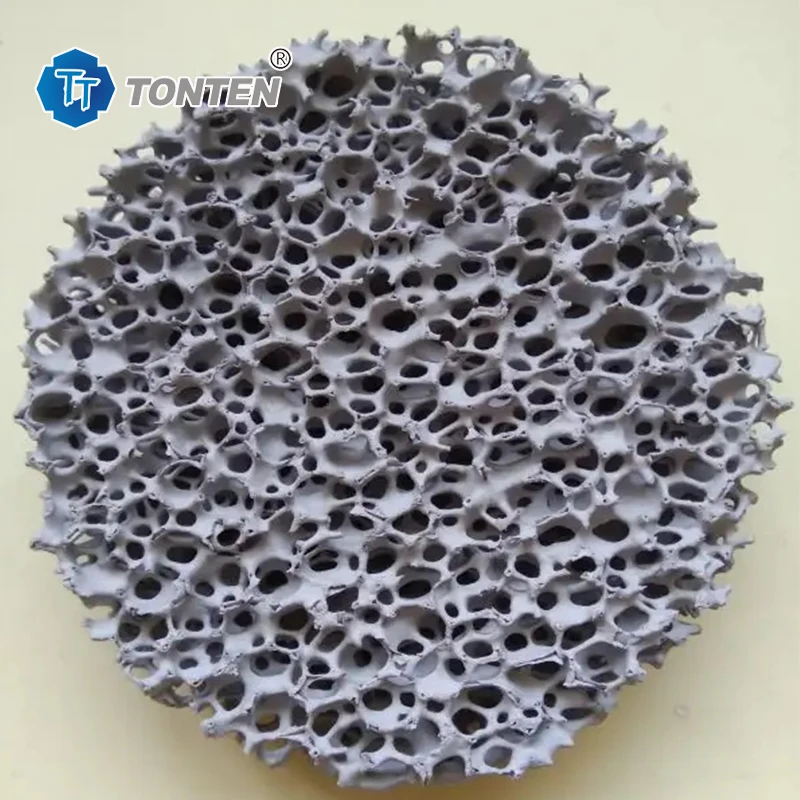

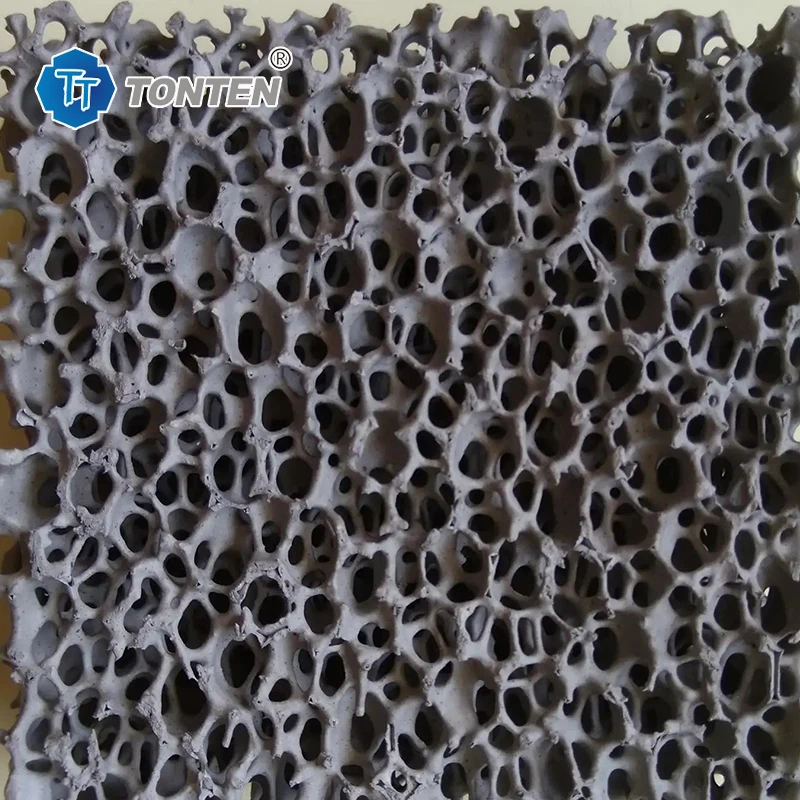

Details determine quality, Know the details of our filter.

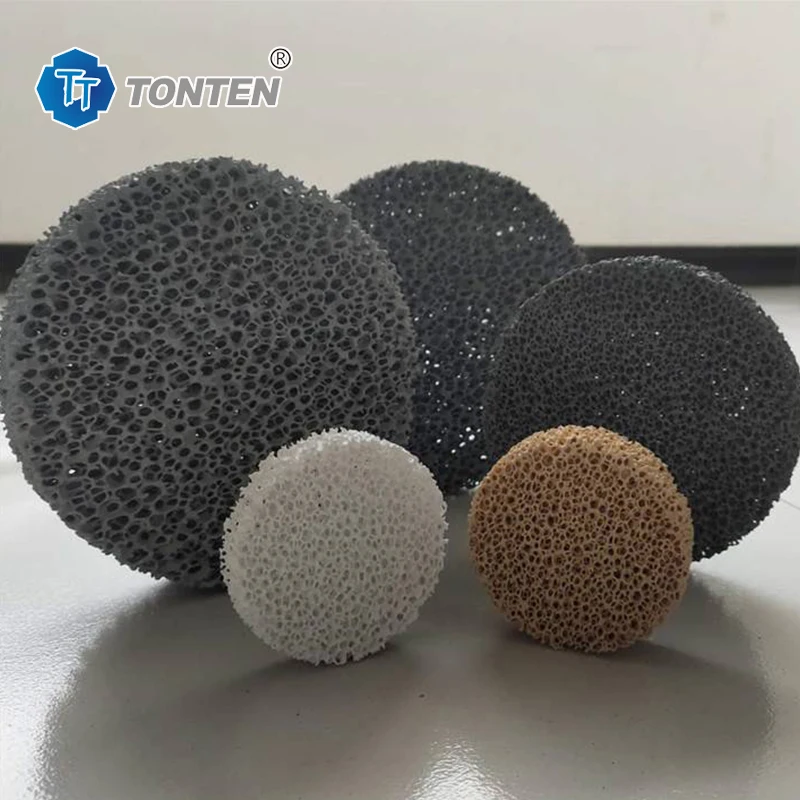

Product Photograph

Pure Ceramic Foam Filter For Titanium Casting High Purity Material Meet Stringent Quality Standards

Contact Us

Please do not hesitate to contact us if any interest in our products.

Package & Shipping

The package and shipping info for aluminum liquid filtration fiberglass filter:

1. The filter cloth for molten metal aluminium can be packed in brown paper bag or plastic woven bag.2. 25kg (55lb)/bag, 40 bags packed in a 1000kg (2200lb) bulk bag.

3. 25kg (55lb)/bag, 40 bags on a 1000kg (2200lb) pallet.

4. 1000kg (2200lb)/jumbo bag.

5. Customized packing available for mesh fiber glass.

Factory Strength

Gongyi Tonten Abrasive Co.,Ltd major in the production and processing of Abrasives, Refractory Material, Filter Material, Wear Resistance Material, Chemical Products, including Aluminium Oxide, Emery, Garnet, Copper Ore, Bauxite, Corundum, Carborundum, Fracturing Proppant, Ceramic sand, Water Clarifying Agent, and so on.

We always strive for our eight core enterprise cultures, which include Study, Innovation, Humanism, Integrity, Teamwork, Efficiency, Passion, Frugality. With a complete and scientific quality control system, our credibility, strength and quality are highly recognized by the whole industry. We sincerely hope to create a brilliant future with our worldwide friends.

We always strive for our eight core enterprise cultures, which include Study, Innovation, Humanism, Integrity, Teamwork, Efficiency, Passion, Frugality. With a complete and scientific quality control system, our credibility, strength and quality are highly recognized by the whole industry. We sincerely hope to create a brilliant future with our worldwide friends.

-- -- Client Feedback -- --

FAQ

1. Who are we?

We are based in Henan, China, start from 2012, sell to Eastern Europe (25.00%), North America (20.00%), Eastern Asia (20.00%), Southeast Asia (15.00%), Western Europe (10.00%), South America (10.00%). There are total about 11-50 people in our plant.

2. How can we guarantee quality?

Always a pre-production sample before mass production. Always final Inspection before shipment.

3.What can you buy from us?

Abrasives, Refractory Material, Filter Material, Wear Resistance Material, Chemical Products.

4. Why should you buy from us not from other suppliers?

We have more than 10 years experience in Abrasive industry and exported to many countries such as Korea, Japan and American markets. With a complete and scientific quality control system,we can supply customized processing according to customers requirements.

5. What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW, Express Delivery.

Accepted Payment Currency: USD, EUR, CAD, AUD, HKD, CNY.

Accepted Payment Type: T/T, L/C, Money Gram, PayPal, Western Union, Cash.

Language Spoken: English, Chinese.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices