Manufacturer Custom High Transparent Anti yellowing Optical Led Silicone Lens For Projector Lens

- Category: >>>

- Supplier: Yejia Optical Technology (guangdong) CorporationYejia Corporation

Share on (1601295629485):

Product Overview

Description

Product Presentation

Custom factory price high temperature resistant high power silicone condenser for LED matrix headlights

Silicone Condenser | |

Optical Liquid Silicone | |

Class 100,000 Clean Production Workshop | |

IATF16949, ISO9001, ISO13485, ISO14001 | |

LSR Injection Molding | |

YJ-99 | |

Hardness | 80 Shore A |

Silicone Optics Optical Performance Comparison

Optical Properties | Dow MS4002 | Momentive LSR7180 | Wacker LR7601/80 | PC | PMMA | Glass |

Light Transmittance (%) | 94 | 94 | 94 | 86-89 | 89-92 | 95 |

Refractive Ratio | 1.41 | 1.41 | 1.41 | 1.59 | 1.49 | 1.5-1.6 |

Haze | - | <1 | - | 1-3 | 2-4 | - |

Abbe | 48 | 50 | 50 | 34 | 57 | 35-59 |

Yellowness Index | - | <1 | - | 1-3 | 1-3 | - |

Optical Liquid Silicone Aging Test

Product Description

Silicone condensers for automotive ADB (Adaptive Driving Beam) matrix LED headlights are a cutting-edge innovation designed to improve the performance, efficiency, and flexibility of advanced automotive lighting systems. Advantages of Silicone Condensers in ADB Matrix LED Headlights:

* Precision and Customization: The use of silicone condensers allows for intricate designs and precise control over light patterns, which is especially important for dynamic ADB systems that need to adjust to various driving conditions.

* Weight Reduction: Silicone condensers are lighter than traditional glass lenses, contributing to overall weight reduction in the headlight assembly, which can improve vehicle efficiency.

* Design Flexibility: Silicone condensers can be molded into complex shapes, enabling innovative and compact headlight designs that are aesthetically pleasing while still providing optimal functionality.

* Long-term Reliability: Silicone materials are resistant to UV radiation, temperature extremes, and aging, leading to headlights that maintain consistent performance over many years.

* Precision and Customization: The use of silicone condensers allows for intricate designs and precise control over light patterns, which is especially important for dynamic ADB systems that need to adjust to various driving conditions.

* Weight Reduction: Silicone condensers are lighter than traditional glass lenses, contributing to overall weight reduction in the headlight assembly, which can improve vehicle efficiency.

* Design Flexibility: Silicone condensers can be molded into complex shapes, enabling innovative and compact headlight designs that are aesthetically pleasing while still providing optimal functionality.

* Long-term Reliability: Silicone materials are resistant to UV radiation, temperature extremes, and aging, leading to headlights that maintain consistent performance over many years.

If you're looking for LED lighting silicone condensers manufacturer, YEJIA Silicone will be the most suitable supplier in China. With in-house mold making department, advanced mold making and silicone molding equipment, class 100,000 clean optical workshop and successful developing experiences for European LED Lighting leaders, we highly welcome custom silicon led condensers.

Product Usage

Silicone Condensers for Automobile ADB Matrix Headlights

Yejia Silicone is experienced in manufacturing custom silicon lenses for automotive headlights makers. With over 94% light transmittance, the silicon lenses is the key component for Adaptive Driving Beam Headlights, which is popular because it makes driving more safe and more convenient at night.

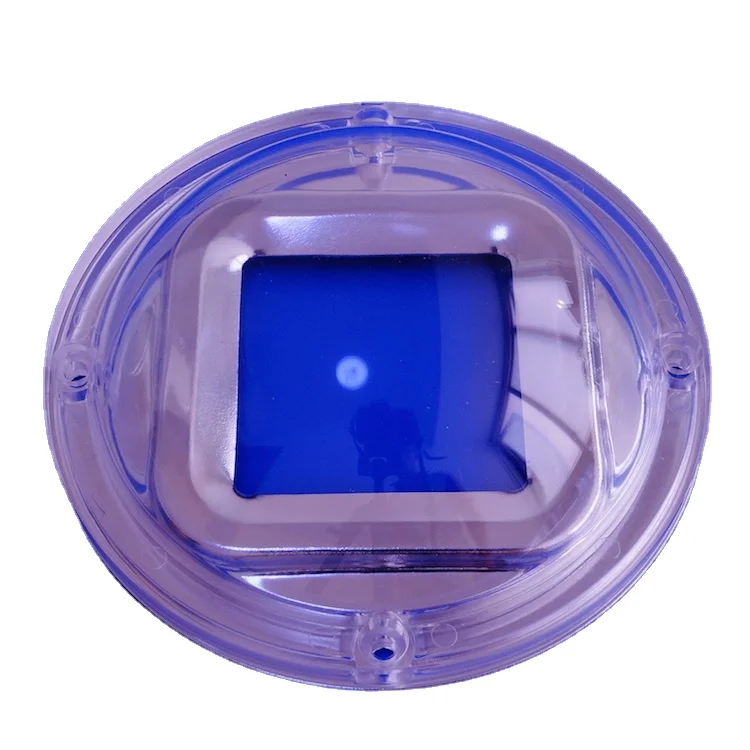

Silicon Lens for Outdoor Smart Floor Lights

The silicon lens is temperature resistant, UV resistant and waterproof, nowadays, more and more customers choose to use the silicon lenses to replace plastic lenses, since it can be used under harsh environments, and the lifetime is longer.

Silicone Optical Lenses for Grow Lights

If you want to cultivate a variety of plants indoors, regardless of the season or amount of sunlight, for sure, you will need the silicon lens, it's UV protection and durable for long-time lighting, for custom silicon lenses, welcome to contact us.

Certificate

Yejia Silicone produces custom silicone products for over two decades, and our factory has been certified by ISO9001, ISO14001, ISO13485& IATF16949. Also, we've been authorized as SONY Green Partner. If you're looking for supplier for high quality silicone optics for LED lights, welcome to contact us.

Related Products

Company Introduction

Yejia Silicone is the silicone division of Yejia Optical Technology (Guangdong) Corporation, which is a subsidiary of YEJIA GROUP, as a high-tech silicone products manufacturer of product design, mold design and making, manufacturing and marketing. Founded in 2009, we’re experienced in mold design and making, liquid injection molding, silicone overmolding, compression molding and plastic injection molding.

We've owned about 10,000 square meters modern workshops, various class 100,000 clean production workshops for silicone injection molding, and 100,000 class clean UV surface treatment workshop for surface treatment of silicone products. There are 39 sets LSR injection molding machines, 6 sets vacuum compression molding machines, and we’re planing to import more ARBURG horizontal liquid injection molding machines for manufacturing optical silicon lenses. Our company has passed the certifications of ISO9001, ISO14001, ISO13485 and IATF16949.

Our main products include but not limited to silicone valves, silicon lens, IP68 waterproof mobile phone and outdoor electronic precision silicone parts, medical silicone balloons, smart wearable silicone covers and watch bands, medical silicone products, high-end beauty silicone products and other custom silicone products.

Our company has become the precision technology manufacturer in the industry of LSR injection molding and silicone overmolding. Directly or indirectly, we provide silicone molding products and silicone moulding services to HUAWEI, GOOGLE, SONY, SHARP, LG, GEELY, SUMITOMO,TUPPERWARE, TAKEYA and other Fortune 500 enterprises.

Saving costs with time, 8 departments and a team of 350 employees, serve for your projects at 24/7 days. With ERP system and MES (Manufacturing Execution System), we can track your orders at any time.

Yejia Silicone is your ideal partner in the field of custom silicone products, welcome to visit our factory at your convenience. Want to custom your own silicone molded products, welcome to contact us.

We've owned about 10,000 square meters modern workshops, various class 100,000 clean production workshops for silicone injection molding, and 100,000 class clean UV surface treatment workshop for surface treatment of silicone products. There are 39 sets LSR injection molding machines, 6 sets vacuum compression molding machines, and we’re planing to import more ARBURG horizontal liquid injection molding machines for manufacturing optical silicon lenses. Our company has passed the certifications of ISO9001, ISO14001, ISO13485 and IATF16949.

Our main products include but not limited to silicone valves, silicon lens, IP68 waterproof mobile phone and outdoor electronic precision silicone parts, medical silicone balloons, smart wearable silicone covers and watch bands, medical silicone products, high-end beauty silicone products and other custom silicone products.

Our company has become the precision technology manufacturer in the industry of LSR injection molding and silicone overmolding. Directly or indirectly, we provide silicone molding products and silicone moulding services to HUAWEI, GOOGLE, SONY, SHARP, LG, GEELY, SUMITOMO,TUPPERWARE, TAKEYA and other Fortune 500 enterprises.

Saving costs with time, 8 departments and a team of 350 employees, serve for your projects at 24/7 days. With ERP system and MES (Manufacturing Execution System), we can track your orders at any time.

Yejia Silicone is your ideal partner in the field of custom silicone products, welcome to visit our factory at your convenience. Want to custom your own silicone molded products, welcome to contact us.

Silicon Lens Production Machine

All silicon lenses are processed by imported Arburg LSR injection molding machines, welcome to visit our factory.

Silicon Lens Molding Process

With experienced engineering team, we have helped many customers to manufacture the custom silicon lenses for automobile headlights.

Advanced Mold Making Equipment

Our factory has imported many world class mold making equipment, and the mold processing tolerance is within 0.001mm.

Quality Control

For optical light performance, we have corresponding testing systems, to ensure the product quality meets customers' requirements.

Packing&Shipping

FAQ

1. Q: Can I get samples?

A: Yes, samples can be provided for checking, shipping costs to be freight collect.

A: Yes, samples can be provided for checking, shipping costs to be freight collect.

2. Q: Why you should choose our factory to be your partner for LSR injection molding silicone led optics?

A: With a professional optics doctors and masters to offer technical support, from the very beginning to evaluate the feasibility of your design to mass production. Also, our factory has many advanced and imported mold making equipment, silicone injection molding and performance inspection equipment.

A: With a professional optics doctors and masters to offer technical support, from the very beginning to evaluate the feasibility of your design to mass production. Also, our factory has many advanced and imported mold making equipment, silicone injection molding and performance inspection equipment.

3. Q: What's the advantage to choose optical silicone to make flexible led optics?

A: Comparing to Plastic, the properties of light transmittance, anti-yellowing and weathering resistance are better. Comparing to Glass, the optical liquid silicone is easy to shape, the fluidity makes the complex or micro-structure designs moldable.

A: Comparing to Plastic, the properties of light transmittance, anti-yellowing and weathering resistance are better. Comparing to Glass, the optical liquid silicone is easy to shape, the fluidity makes the complex or micro-structure designs moldable.

4. Q: Can you design silicone led optics?

A: For now, we just do OEM designs. Our team is unable to do the product design.

5. Q: What should I offer to custom silicone led optics with light guides?

A: Please offer us 3D drawing and performance requests.

6. Q: Can I visit your factory?

A: Yes, welcome to contact us to arrange the visiting time.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices