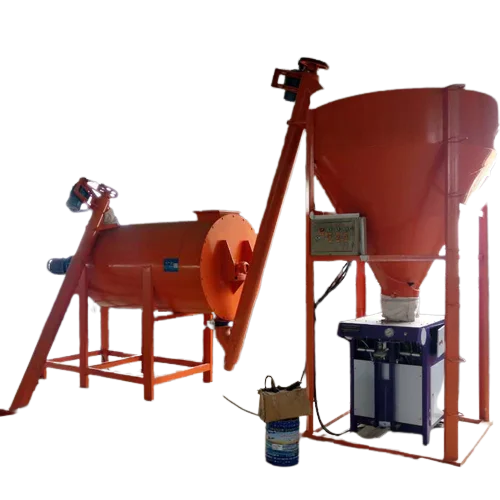

Dry Mix Concrete Batch Plant high accuracy Tile Adhesive Mortar Mixing Plant For Sale 3000kg/batch Capacity Mortar Mixing Plant

- Category: >>>

- Supplier: Zhengzhou Xinyu Machinery Manufacturing Co. Ltd.Zhengzhou Ltd.

Share on (1601296129983):

Product Overview

Description

Simple and practical small type dry mortar plant is designed based on the traditional mixer, is added a material conveying system, a storage bin and an automatic filling machine. The well-mixed materials will go into the storage bin via material conveying pipe, and the mixer may be feed consecutively and work continuously in flow line production, but the equipment is not over 4 meters high, thus solving the problem of heightening the workshop. Moreover, it may realize automatic metering and filling, hence, it may not merely save the time and energies but also may be more accurate. Requiring little investment, but it may load, weight and package the materials automatically; no wondering, it is a simple but practical production line.

Item | 1ton/batch | 2tons/batch | 3tons/batch | 4ton/batch | 5tons/batch |

Mixing power | 5.5KW | 7.5KW | 15KW | 11KW | 22KW |

Feeding conveyor power | 3KW | 3KW | 4KW | 4KW | 4KW |

Second conveyor power |

| 4KW | 4KW | 4KW | 5.5KW |

Mixing time | 5-8minutes | 5-8minutes | 5-8minutes | 5-8minutes | 5-8minutes |

Model | Capacity | Area (Square meters) | Height | Note |

Simple | 1-5t/h | 40 | 3m | Manual batching and packing |

Basic | 5-15t/h | 40-60 | 6-10m | Manual batching ,automatic packing |

Semi Automatic Serial | 5-15t/h | 40-80 | 8-12m | Automatic batching of coarse material,manual batching of additive ,automatic packing |

Full Automatic | 5-50t/h | 40-100 | 10-25m | Automatic batching of coarse material,manual batching of additive,automatic packing |

Full Automatic Tower | 55~100t/h | 60~500 | 10-30m | Automatic batching of coarse material,manual batching of additive,automatic packing |

Application | |

Bonding Mortar | Masonry mortar, wall and floor tile adhesive mortar, anchorage mortar etc. |

Decoration mortar: | Decorative plaster, inner and outer wall putty, colorful decoration mortar etc. |

Protection mortar: | Water-proof mortar, anti-corrosion mortar self-leveling mortar, wear resistance mortar, thermal insulation mortar, sound insulation mortar, repair mortar, mildew-proof mortar, shielding mortar etc. |

We mainly engaged in providing turn-key service to numerous customers with engergy-saving and efficient practical solutions. Main advantage of dry powder mixing equipment from Zhengzhou Xinyu Machinery Manufacturing Co., Ltd:

* Over 30 years experience in this line. Zhengzhou Xinyu dedicated in the research and development of dry powder mixing equipment for decades, we are in a leading position in this trade;

* We provide to customers with combat experience of construction management and multiple efficient project solution.

* The special additives from Zhengzhou Xinyu guranteed the quality of dry mortar from our clients.

We promise to all customers that: upon you choose our services and products, we will provide the first-class product quality, latest technology in mortar formula, and special additives; we ensure the good quality of dry mortar produced by our equipment.

1.We have more than 60 machines and will guarantee the short production time and good quality.

2.We are located in Henan Province China,the largest construction town,there is a large advantage on experience and cost.it is easy for you to visit our company and the factory.we will also provide you 24h online chat service.

3.Online chat,quick reply,good quality.

4.We have sell lots of construction equipment,that can demand different purchase demand,it is convenient.

5.We have gained a global sales network reaching in Uganda,Colombia, Bolivia,Brazil,Algeria, Ecuador, Russia, Pakistan, Vietnam, Dubai, Ghana, India and so on. The quality,the price,the delivery time will be the best.

1.A set of wear out spare parts for free.

2. Warranty: 18 Months

3. About Installation:

1) We will Provide installation instructions.

2) We will Provide installation videos.

3) Excellent engineers will be online guide the installation.

Q1 How about the investment of this project?

A: Our engineer can design the dry mortar plant as your requirement and your budget, different dry mortar plant investment are difference.Low capacity low cost, we will provide you cost effective solutions as your requirement.

Q2 What's the difference between full automatic dry mortar plant and Semi-automatic dry mortar plant?

A: (1) Semi-automatic dry mortar plant is cheaper than full automatic dry mortar plant.

(2) Semi-automatic dry mortar plant do not need to equip silos while full automatic dry mortar equip material silos.

(3) Semi-automatic dry mortar is manual feeding and automatic weighing and packaging, Full automatic dry mortar plant is automatic feeding and automatic weighing and packaging.

Q3 How many person required to operate this dry mortar plant?

A: Usually 2-4 workers are enogh to operate this dry mortar plant.

Q4 What equipment and services you can provide?

A: We can provide you turnkey solution of dry mortar plant from working site planning to dry mortar machines, transportation, installation and training, formula of dry mortars, after-sales services, life time technical support .

Q5 What is the area required for this dry mortar plant?

A: According to the capacity of the dry mortar plant, the area required 300-100 m2.

Q6 What is the total power consumption (KW) of this dry mortar plant?

A: It is 20-80W based on the capacity of the dry mortar plant.

Q7 What is the capacity of your dry mortar plant?

A: We have dry mortar plant with capacity 3-30T/H as your requirement, and also we can customize the dry mortar plant as your capacity requirement.

Q8 How long is the guarantee period?

A: 12 months, within this period, we provide you spare parts and services for free.

Q9 Can you install the dry mortar plant in my country?

A: Yes, we will send engineers to your country for guiding installation and training your workers to operate the machine.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices