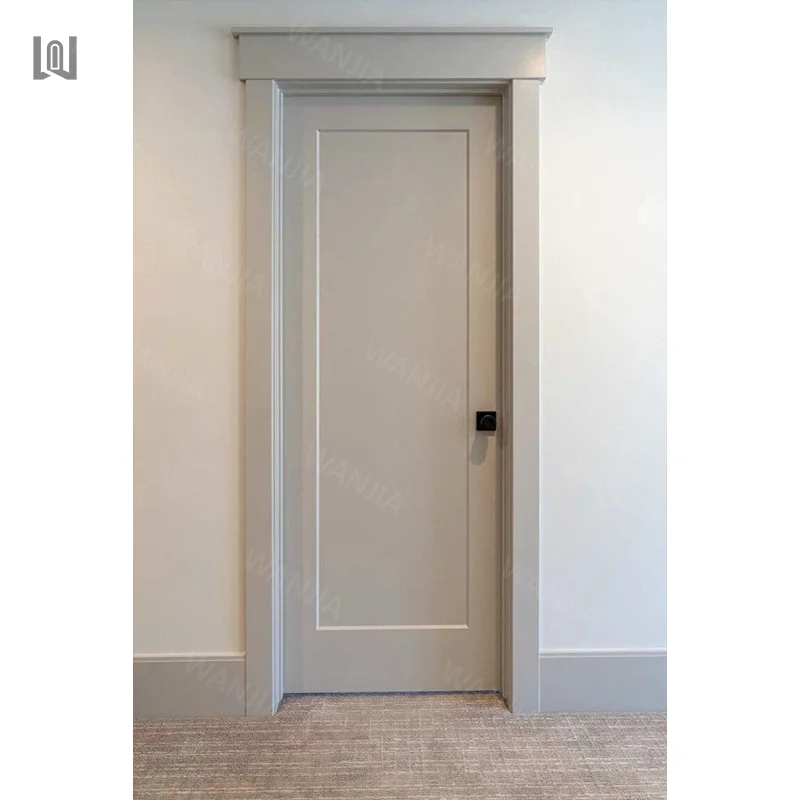

Wholesale High Quality Wood Interior Room Inside Doors Chinese Interior Doors For Houses

- Category: >>>

- Supplier: Linyi Oupanpan Door Industry Co. Ltd.Linyi Ltd.

Share on (1601296268775):

Product Overview

Description

OPANPAN DFL-30P series Composite Wooden Doors

Section 1: | Materials of Door Skin | |||||||

Opanpan Carbon Fiber MDF Door Skin DFL-30P Series are made of carbon fiber MDF panel and melamine paper without painting process. Carbon fiber MDF is rich in activated carbon negative ions.It can decompose formaldehyde produced during home decoration and absorb odors such as benzene and TVOC.At the same times ,it can release negatiive oxygen ions to purify the air. | ||||||||

Carbon fiber MDF is rich in activated carbon negative ions.It can decompose formaldehyde produced during home decoration and

absorb odors such as benzene and TVOC.At the same times ,it can release negatiive oxygen ions to purify the air.

MDF has a moderate density, which gives it good machining properties. At the same time, it can be glued and inlaid with various

veneers, acrylic or metal sheets to meet different aesthetic needs.

absorb odors such as benzene and TVOC.At the same times ,it can release negatiive oxygen ions to purify the air.

MDF has a moderate density, which gives it good machining properties. At the same time, it can be glued and inlaid with various

veneers, acrylic or metal sheets to meet different aesthetic needs.

The melamine paper is formed by three layers as:Top paper is the outermost protective layer, which makes the door skin hard, wear-resistant and highly transparent. Decorative

paper is located under the top paper, which plays a decorative role and has good hiding power, impregnation and printing properties. Bottom paper is made of phenolic resin glue as a mechanical support to provide structural stability for the door skin.

paper is located under the top paper, which plays a decorative role and has good hiding power, impregnation and printing properties. Bottom paper is made of phenolic resin glue as a mechanical support to provide structural stability for the door skin.

1. Adsorption | 2. Decompostion | 3. Negative oxygen ions |

Nano-crystal micropores strongly adsorb formaldehyde, benzene, TVOC and other odorous or toxic gases. | Nano-catalysis strongly decomposes the adsorbed formaldehyde and other harmful substances. | Release negative oxygen ions in real time, truly achieving a three-layer purification effect. |

Section 2: Contemporary minimalist design of composite wooden doors | ||

Within the maximum size limit, customers can freely customize the size of the door.Within simultaneous molding、carving and inlaying etc. processes, the door skins derives various designings and all of them can be customized according to customer requirements. | ||

Max size of customizatiion | 2250×950mm | |

Thickness of door leaf | 45mm or Customization | |

Section 3: | Surface treatment | |||||||

The decorative panels can be freely customized by carving, molding, and inlaying etc.MDF can be molded, carved, inlaid, and matched with various patterns of melamine paper to produce door panels of different styles to meet the customization requirements of various customers. | ||||||||

Section 4: | Colour of surface | |||||||

Door panel design is produced by the pattern of melamine paper, combined with molding, carving and inlaying etc. processes. The common patterns of melamine paper are as follows, and it can also be customized according to customer requirements. | ||||||||

Section 5: | Filling Materials of door | |||||||

The filling materials in the door panels are mainly composed of solid wood, bridge hole boards, MDF, honeycomb paper and graphene,which can be mixed and matched. The above materials have different performances in terms of door panel strength, sound insulationand weight. Customers can customize according to their actual needs. | ||||||||

Graphene | 3D Silent Mechanical Board | Bridge Hole Knot Board | ||||

Graphene has high strength, hardness and certain toughness, which can effectively prevent door panel deformation. It also has thermal conductivity and flame retardancy, which can improve the thermal insulation effect of door panels and enhance the fire resistance level. The honeycomb structure of graphene helps to reduce noise. Moreover, it is environmentally friendly and non-toxic, which meets the environmental protection requirements of modern homes. | The three-dimensional silent mechanical board has excellent bending strength and bearing capacity, keeping the door leaf from deforming. Compared with traditional materials, the three-dimensional silent echanical board is lighter, which helps to lower the overall center of gravity of the door body, improve stability and movement speed. The structure of the three-dimensional silent mechanical board helps to improve the sound insulation effect of the door and provide a comfortable indoor environment for residents. | The bridge hole knot board has good waterproof performance, and effectively prevents temperature from overflowing, and has good thermal insulation effect. The bridge hole knot board is thicker, and the sound insulation effect can reach 33 decibels. Thebridge hole board door meets the E1 environmental protection standard, and the free formaldehyde emission is low, which isharmless to the human body. The internal force of the bridge hole knot board is uniform, not easy to deform, and it can remain stable even in a humid environment. | ||||

Section 6: | Decoration scene | |||||||

After the decorative panels and fillers are bonded, molded, cut, and edge-sealed, a relatively complete door leaf is formed. The door leaf has many excellent properties, such as environmentally friendly, formaldehyde-free, waterproof, soundproof, and scratch-resistant. Customers can freely customize various door locks and hinges installation on the completed door leaf. * Conventionally, 5mm or 8mm MDF veneer as decoration door skin panel, and various shapes can be customized and carved. * The four sides of the door leaf, the lock location and the internal frame structure are all made of multi-layer solid wood , which provides a thick and stable solid wood feel. * Double-sided non-painting process, environmentally friendly, waterproof and wear-resistant. * Various designs are available, which can be adapted to various architectural styles of different regions and cultures. * The internal filling can be freely selected from solid wood square, bridge hole board, honeycomb paper, and graphene etc., with excellent noise reduction effect. | ||||||||

Section 7: | Introduction of Opanpan | ||||||

About Opanpan | ||||||||

As a manufacturer, Linyi Oupanpan Door Industry Co., Ltd.(short for Opanpan) specializes in the R&D and production of decorative door skins, wall panels, molding lines and finished doors. The main type of decorative door skins is density board veneer melamine paper. It derives various decoration styles through molding , carving ,inlaying etc. processes. At the same time, Opanpan produces wall panels and molding lines in the same color as the door skin. It enables decoration service providers who cooperate with Opanpan to provide their customers with more design-oriented service solutions. With the fact that finished door filling materials,such as brigde structure particleboard,graphene,honeycomb papaer ,are all under Opanpan Self-operated R&D and production, it prompts Opanpan master the core technologies in interior door key indicators as quietness, fire resistance and waterproofness etc. | ||||||||

Qualifications and certificates | ||||||||

Production site | ||||||||

Melamine Door Skins Proudct Line

The Zenith extreme heat treatment medium density fiberboard production line made in Germany can better make the surface film and the base board fit together, and the process is environmentally friendly and meets EU requirements. The board processing surface is flat and consistent, the cooling time is reduced, the service life is long, and it is convenient for subsequent processing.

Hexagonal saw production line

Oupanpan uses advanced fully automatic PLC hexagonal saw production technology to ensure the accuracy of the size of the board and door panels. The cut surface is flat, which is conducive to the next step of the hemming process. The four edges are guaranteed to be parallel and vertical, which increases the rate of finished door panels.

Opanpan Direct-operated storage center | Door panel Deep Processing | ||||||

Taking advantage of Linyi as the logistics capital, Oupanpan's self-operated logistics center can quickly and safely deliver logistics to distributors across the country. Thanks to the location advantage of Qingdao Port, the largest port in Asia, Oupanpan can meet the shipping needs of global door industry buyers. | Door panels can be processed through punching, inlaying, glass configuration, hardware and other subsequent processes according to different customer requirements. Opanpan continues to update and iterate the design style of door panels to meet the requirements of customers from different countries and regions with different cultural backgrounds. | ||||||

FAQ-01 | Who is Opanpan? | ||||||

opanpan | As a manufacturer, Linyi Oupanpan Door Industry Co., Ltd.(short for Opanpan) .Main products of Opanpan include MDF door skins,Melamine door skins,Melamine wall panel,moulding and finished wooden doors.Opanpan is located in Linyi, China, which is known as the world's board capital.Welcome to opanpan! | ||||||

FAQ-01 | Can you produce according to the drawing provided? | ||||||

opanpan | Yes,we can.Oupanpan engineers will confirm all production details with customers in the form of drawings before order production. | ||||||

FAQ-01 | Do you accept OEM cooperation? | ||||||

opanpan | Yes, customers are required to provide proof of their right to use the trademark or brand. | ||||||

FAQ-01 | Will you assist customers with installation? | ||||||

opanpan | According to customer requirements, we can dispatch installation engineers to the country where the customer's project is to be constructed to provide technical guidance.According to customer requirements, we can dispatch installation engineers to the country where the customer's project is to be constructed to provide technical guidance. | ||||||

FAQ-01 | How is your aftersales service? | ||||||

opanpan | We will give your refund or replacemnet if there is quality problem about our products. | ||||||

Name | Christopher Lee |

Whatsapp | +8613721998799 |

Email | yingchao.lee@hotmail.com |

We Recommend

New Arrivals

New products from manufacturers at wholesale prices