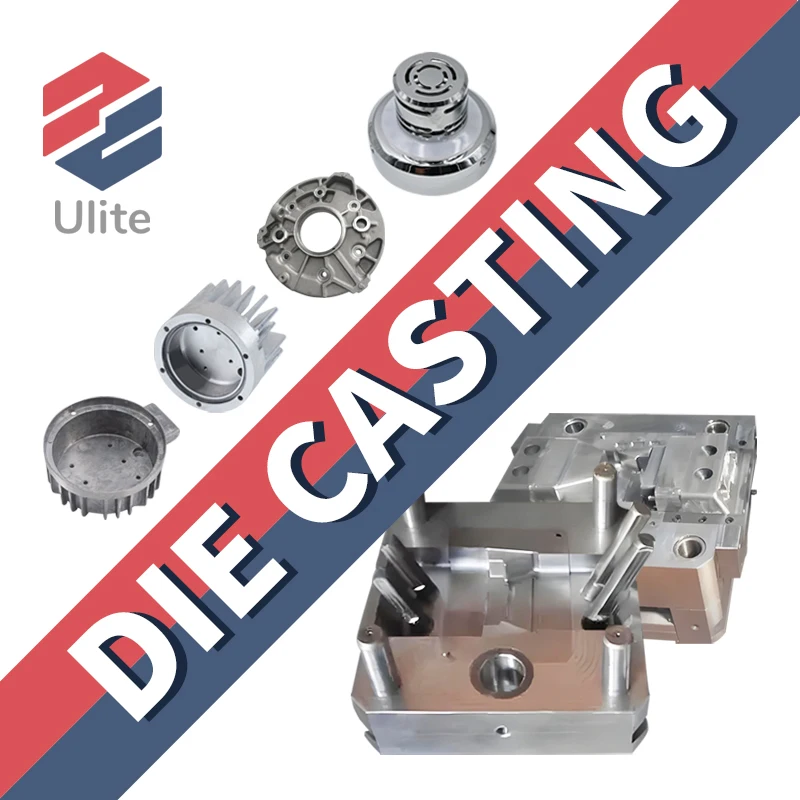

Ulite Die Casting Manufacturers Custom Aluminum Die Casting Mold

- Category: >>>

- Supplier: Shenzhen Ulite Precision Tech LimitedShenzhen Limited

Share on (1601296892015):

Product Overview

Description

Our Service

One-stop Injection Mold Manufacturing & Plastic Parts Production Assembly

1) 3D File (STEP/STP/IGS/STL format)

2) Part Material

3) Order Quantity

4) Surface Finish & Color (if required)

Detailed and comprehensive information will be more effective in moving forward.

☞ >Click on Send Inquiry or Chat Now

We will quickly provide you with professional advice to save mold costs and maintain high quality.

☞ >Click on Send Inquiry or Chat Now

We will quickly provide you with professional advice to save mold costs and maintain high quality.

How To Start Order

Mold Description

Mould Details -

Name | Plastic Injecition Mold |

Mould core | P20,NAK80,SKD11,S316,S50C,S45C,718H,718 or customers' appointed |

Mould base | LKM, HASCO, DME or upon customer's requirement |

Type of plastic mold | 3-plate mold,2-plate mold |

Cavity | Single/Multi 1*1,1+1,1*2,1+1+1,etc |

Mode Gate | Fan gate,Sub gate,Pin Point gate,Valve |

Ejection system | Stripper plate,Lifter,Push Bar,Ejection Pin etc |

Runner | Hot/cold type |

Plastic material | HDPE, PP, nylon, PEEK, LDPE, ABS, styrene, acrylic, acetal, PE, PTFE, PEI, and PES |

Mould life | 300,000-1,000,000 shots |

Lead time | 15-35days after deposit received |

Specification | Follow the 3D final drawing |

Packaging details | covering with film for anti rust and packed with wooden Case |

Parts Production Details -

Product Material | ABS,AS,PP,PPS,PC,PE,POM,PMMA,PS,HDPE,TPE,TPU etc |

Surface finish | Polishing finish,Texture Finish,Glossy Finish,Painting,Slik print,Rubber Painting etc |

MOQ | 500 PCS |

Packaging details | Carton box or wooden Case upon product weight and customer's requirements. |

Shipping | By sea or by air as customer requirement |

Export Country | Janpan,Europe,USA,Mexico,Australia,Middle East,Korea,Asia etc |

Typical Used For | Housings, containers, caps, fittings,including as below Power-tool housing, Disposable razors, Electrical Switches,Crates/Recycling boxes Automotive dash boards,Television Cabinets,Drug Inhalation Units,Automotive bumpers, Wheelie bins ,Syringes,Telephone handsets ,Washing-up bowls,DVDs, Bottle Lids/closures,Battery Casings |

Range of markets | industrial, consumer, food processing, aviation, seals/gaskets, lighting, packaging, filter, healthcare, telecommunications, mechanical, water treatment, appliance, recreation, lawn and garden, educational, oil and gas, government, construction, plumbing, surveillance, pumps, marine, motors, gears, RFID tags, electronics, and fasteners. |

Plastic Applications

FAQ

Q1: What is die casting?

A1: Die casting is a common metalworking process in which molten metal is injected under high pressure into a metal die casting mold and then cooled and solidified in the mold to form the desired part or product.

Q2: Are you an Parts or molds factory?

A2: Yes, We can provide one-stop service for mold making and plastic/metal parts production and assembly

Q3: What is your die-casting process ?

A3.: We use advanced die casting process, including cold chamber die casting and hot chamber die casting technology, to ensure the precision and quality of our products.

Q4. How do you ensure product quality?

A4. We have ISO9001 ISO14001 and other quality management system certifications, including the whole process control from raw material procurement to final product testing, to ensure that our products meet the technical requirements and standards of our customers.

Q5. How much does it cost to make die casting molds and parts?

A5. We will provide detailed quotations according to the design drawings and requirements provided by customers, and also provide discount policies according to the size of the order to ensure that customers get competitive price advantages.

Q6: What is your production lead time ?

A6: Usually 3-5 weeks, the fastest is 1 week, depending on the specification of the mold and the complexity of the structure. For your urgent projects, we can work overtime to shorten the delivery time.

Q3: What is your die-casting process ?

A3.: We use advanced die casting process, including cold chamber die casting and hot chamber die casting technology, to ensure the precision and quality of our products.

Q4. How do you ensure product quality?

A4. We have ISO9001 ISO14001 and other quality management system certifications, including the whole process control from raw material procurement to final product testing, to ensure that our products meet the technical requirements and standards of our customers.

Q5. How much does it cost to make die casting molds and parts?

A5. We will provide detailed quotations according to the design drawings and requirements provided by customers, and also provide discount policies according to the size of the order to ensure that customers get competitive price advantages.

Q6: What is your production lead time ?

A6: Usually 3-5 weeks, the fastest is 1 week, depending on the specification of the mold and the complexity of the structure. For your urgent projects, we can work overtime to shorten the delivery time.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices