Easy Operated Portable Aluminium a Frame Lifting Gantry Crane On Sale

- Category: >>>

- Supplier: Henan Huasui Heavy Industry Machinery Equipment Co. Ltd.Henan Ltd.

Share on (1601297654290):

Product Overview

Description

Products Description

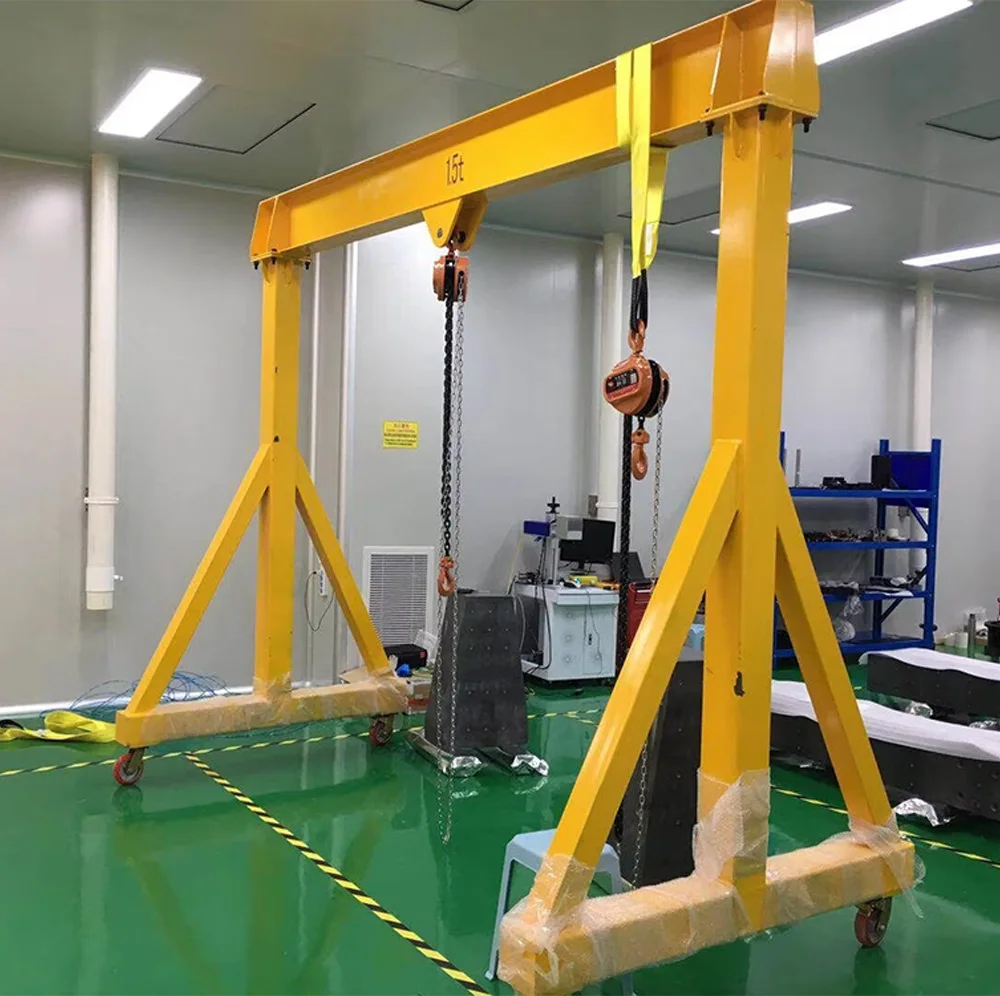

Easy Operated Portable Aluminium a Frame Lifting Gantry Crane On Sale is a type of crane that is designed to be easily transported from one location to another. It consists of a horizontal beam or "gantry" that is supported by legs or wheels and can be raised or lowered by a large electric motor. The gantry can also be moved horizontally along the length of the crane, allowing it to reach over long distances. The crane typically has a control cabin mounted on the gantry, which houses the controls for the crane's movement and lifting capabilities. The operator sits in the cabin and uses a joystick or other controls to move the crane and lift loads.

Portable gantry cranes are commonly used in construction, manufacturing, and material handling industries for tasks such as lifting and moving heavy objects, loading and unloading trucks and railcars, and positioning materials and equipment. They are particularly useful in situations where a fixed crane is not feasible or practical, such as in remote locations or on job sites with limited space.

Features

Lightweight and Durable

Made from lightweight but sturdy materials like aluminum or steel. Aluminum models are ideal for easy transport, while steel options provide more strength for heavier loads.

Adjustable Height and Span

Telescoping legs enable height adjustment to accommodate different working environments or ceiling heights. The span of the crane can often be adjusted to fit the width of the load or workspace.

Quick Assembly and Disassembly

Designed for fast setup and takedown, making it convenient for temporary or mobile work sites. Can often be broken down into components for easy storage or transport.

Customizable Options

Available with options like motorized movement, hoists, or trolleys to cater to specific lifting needs.

Mobility

Equipped with swivel casters or wheels, allowing it to be easily moved across flat surfaces.

Detailed Images

Hoist

A lifting mechanism mounted on a trolley, used to raise or lower a load. Depending on the purpose of the crane, it can be a manual hoist, electric chain hoist or wire rope hoist.

Casters (Wheels)

Swivel or fixed wheels attached to the bottom of the legs for mobility. Typically made of steel, rubber, or polyurethane, depending on the operating environment.

Legs

A lifting mechanism mounted on a trolley, used to raise or lower a load. Depending on the purpose of the crane, it can be a manual hoist, electric chain hoist or wire rope hoist.

I-Beam (Horizontal Beam)

This is the horizontal beam spans between the two legs of the crane. The hoist and trolley system typically move along this beam to lift and transport loads.

Technical Parameter

Item | Parameters | ||||||||||

Capacity | 0.5 ton | 1 ton | 2 ton | 3 ton | 5 ton | 10 ton | |||||

Span | 2m~12m (as your require) | ||||||||||

Height | 1-10m (as your require) | ||||||||||

Wheel | 4 | ||||||||||

Lifting Mechanism | Manual/Electric wire rope or Chain hoist | ||||||||||

Power | 380V 50HZ 3P or customized | ||||||||||

Note | customized deisgn is acceptable | ||||||||||

Workshops and Small Factories

Ideal for small to medium-sized loads that need to be moved within confined spaces.

Construction Sites

Transporting materials like steel beams, tools, and construction components around the site.

Warehouse Operations

Move heavy pallets, load and unload trucks, or relocate products within storage areas.

About Our Factory

Certifications

Packing & Delivery

FAQ

1. What types of cranes do you offer?

As a manufacturer with over 20 years’ experience, Huasui provide a range of cranes, including gantry cranes, overhead cranes, RTG cranes, jib cranes, and customized lifting solutions tailored to specific industry needs, such as for steel, precast concrete, and container handling.

2. How do I know which crane is suitable for my project?

Our team of experts is here to help! By understanding your lifting capacity requirements, operational environment, and usage frequency, we can recommend the ideal crane solution for your project. Contact us for a free consultation.

3. How to choose the right crane?

The following factors need to be considered when choosing a crane: Load capacity, Lifting height, Working environment, Frequency of operation.

4. What maintenance services do you offer?

We offer comprehensive maintenance plans, including preventive maintenance, inspection, repair, and spare parts replacement, to keep your crane running efficiently and safely. Our service team is available for scheduled and emergency support.

5. Are your cranes compliant with international safety standards?

Absolutely. Our cranes are manufactured in compliance with major international standards such as ISO, EN, and GB/T. Additionally, we ensure that each crane undergoes rigorous testing and inspection before delivery.

6. What are your delivery and installation timelines?

Delivery and installation timelines vary based on the type and customization of the crane. Generally, standard cranes can be delivered within 6–8 weeks, while customized solutions may require additional time. We aim to provide accurate timelines upfront to ensure smooth project planning.

7. Do you offer installation services?

Yes, we provide comprehensive training programs for crane operators, including safety training, maintenance guidelines, and operational best practices to ensure your team is fully prepared to operate the crane safely and efficiently.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices