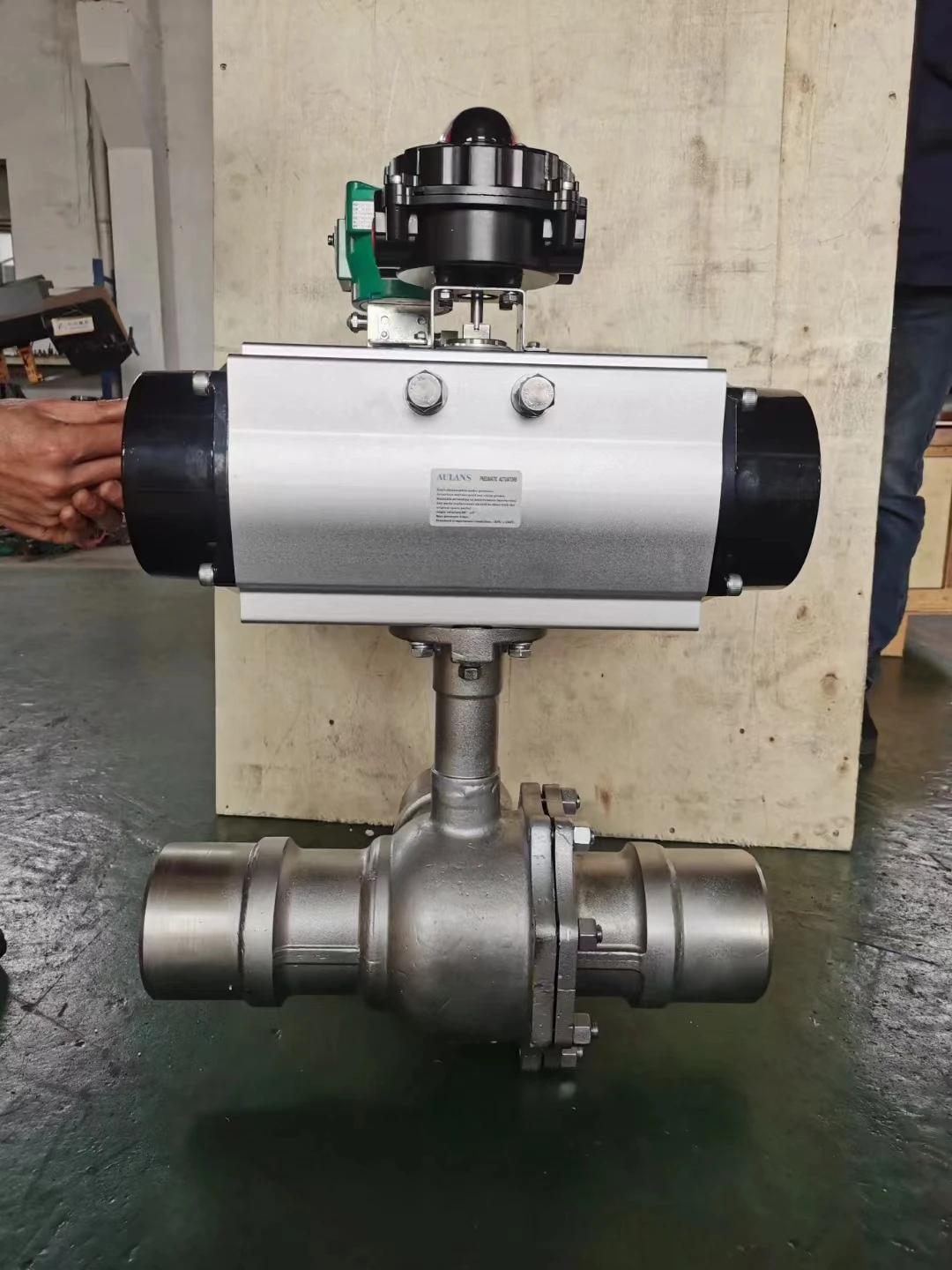

196degree Ultra Low Temperature SS304 Extended Stem Female Welded Pneumatic Cryogenic Ball Valve for liquid oxygen

- Category: >>>

- Supplier: Shanghai Bomo Electromechanical Co. Ltd.Shanghai Ltd.

Share on (1601298481411):

Product Overview

Description

Product specification: | ||||||||

Nominal diameter | PN1.6MPA | |||||||

Applicable medium | liquid nitrogen, liquid oxygen, liquefied natural gas, etc | |||||||

Applicable temperature | - 196 ℃~+80 ℃ | |||||||

2. The sealing surface is made of fluoroplastic, and the sealing pair materials are matched reasonably with long service life.

3. The ball and PTFE valve seat are tightly sealed, with zero leakage function, and can use its plastic deformation to automatically compensate the error caused by wear, so as to achieve good sealing performance and long service life. In order to ensure the sealing at the valve stem, a stuffing box and a gland are added on the valve body for sealing.

4. Various pipe flange standards and flange sealing surface types can be selected, and manual, worm gear drive, electric, pneumatic, hydraulic and other drive modes can also be selected to meet the different needs of users.

The main parts of the cryogenic ball valve shall be subject to low-temperature treatment and each batch of samples shall be subject to low-temperature impact test to ensure that the valve will not be brittle under low-temperature working conditions and can withstand the impact of low-temperature medium.

2. Upper sealing test at room temperature and low pressure;

3. Low temperature upper seal air tightness test (when there is upper seal);

4. Low temperature gas seal test, etc., to ensure that the whole low temperature valve meets the requirements of the standard;

5. Low temperature treatment shall be carried out for main parts and components, and low temperature impact test shall be carried out for each batch of sampling to ensure that the valve will not be brittle under low temperature working condition and can withstand the impact of low temperature medium

Q1. Can I have a sample order for valve?

A: Yes, welcome sample order to test and check quality.Mixed samples are acceptable.

Q2. How do you ship the goods and how long does it take to arrive?

A: We usually ship by sea. It usually takes 15-20 days to arrive.Airline shipping also optional.

Q3. How to proceed an order for valve?

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

Q4. The logo and the color can be customized?

A. Yes, we welcome you to sample custom.

Q5. Any other good service your company can provide?

A. Yes,we can provide good after-sale and fast delivery.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices