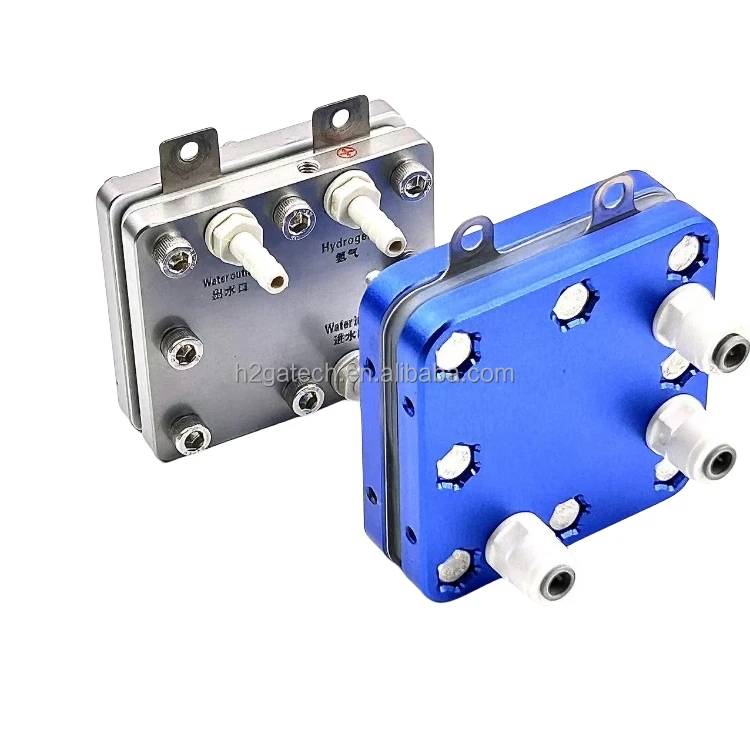

OEM PEM Hydrogen Breathing Machine 900ml Electrolyzer with Nafion N117 Membrane Hydrogen Generator

- Category: >>>

- Supplier: Gatechn New Energy Technology (shanghai) Co. Ltd.Gatechn Ltd.

Share on (1601298948660):

Product Overview

Description

Product Description

Product Presentation

Advantages of PEM:

1. Pure water used by PEM electrolyzer avoids potential environmental pollution and is friendly to the environment;

2. PEM has low resistance and gas permeability, making the current density, working efficiency and gas purity high;

3. The fast response of PEM electrolyzer makes it adaptive to the volatility of renewable energy.

Type | H2G-900ml |

Hydrogen Production ( ml/min) | 900 |

DCA (Rated Current) | 49 |

DCV (Voltage Range) | 5.4-7.5 |

Energy Consumption (kW·h/m3) | ≤4.50 |

Numbers of Cell | 3 |

Electrolysis Efficiency | 80% |

Operating Temperature (℃) | 40-50 |

Water Quality Requirement (MΩ·cm²) | ≥15 |

Hydrogen Side Pressure (MPa) | ≤0.5 |

Water Side Pressure(MPa) | ≤0.5 |

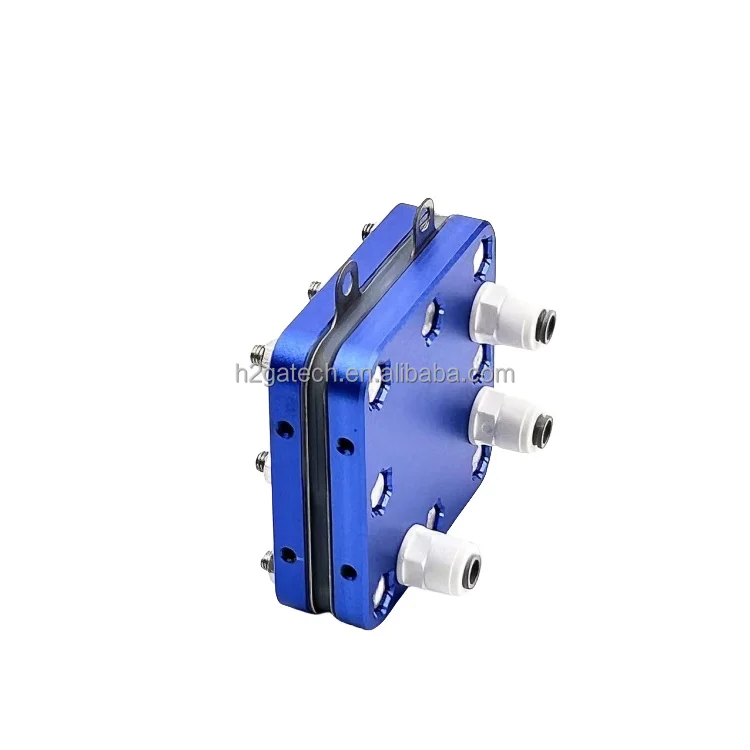

Electrolyzer Dimensions (mm) | 145*124*45 |

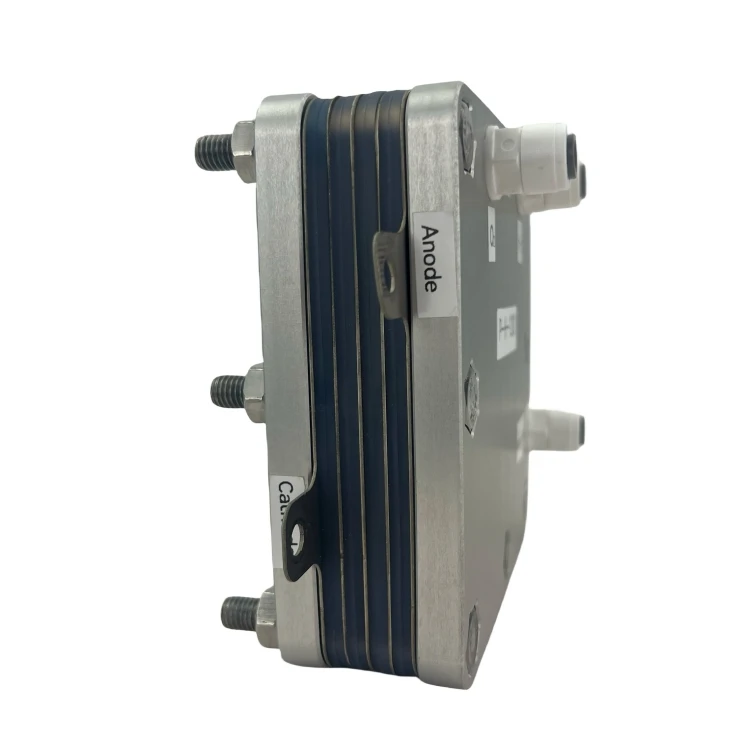

Electrolyzer Structure

PEM Electrolyze Cell

PEM electrolyze is typically composed of end plate, diffusion layer, catalyst layer and proton exchange membrane.

The role of end plate is to fix components, guide current and help distribution of water and gas.

The diffusion layer plays a role as current collector and promote gas-liquid transport.

The role of end plate is to fix components, guide current and help distribution of water and gas.

The diffusion layer plays a role as current collector and promote gas-liquid transport.

H2gatech-Structure diagram of PEM Electrolyze

The core of the catalyst layer is the Triple Phase Boundary (TPB) consisting of catalyst, electron and proton conduction medium, where the electrochemical reactions take place.

For higher hydrogen production rates, a PEM electrolyze is typically stacked with 5 to 100 cells in series.

For higher hydrogen production rates, a PEM electrolyze is typically stacked with 5 to 100 cells in series.

Detailed Images

Core component of electrolyzer: Ordered Membrane Electrode

MEA (Membrane Electrode Assembly) is composed of diffusion layer, catalyst layer and proton exchange membrane.

MEA (Membrane Electrode Assembly) is composed of diffusion layer, catalyst layer and proton exchange membrane.

High specific surface area: compared with ordinary membrane electrode, the active area is increased by more than 50%.

High electron conductivity: the electron conductivity is improved with arrayed catalyst.

Corrosion resistance at high potential: our electrolyzer can work normally at higher potential.

Mesoporous structure: can improve mass transport at the interface.

High electron conductivity: the electron conductivity is improved with arrayed catalyst.

Corrosion resistance at high potential: our electrolyzer can work normally at higher potential.

Mesoporous structure: can improve mass transport at the interface.

Proton Exchange Membrane

Customized catalyst

Customized Membrane Electrode

Electrolyzer Assembly

The electrolyzer adopts zero - distance structure to improve assembly efficiency and maintain strong sealing and low contact resistance.

The energy consumption of the electrolyzer has been greatly reduced with the overall efficiency increased from 73% to 84%.

The energy consumption of the electrolyzer has been greatly reduced with the overall efficiency increased from 73% to 84%.

Product detail drawing

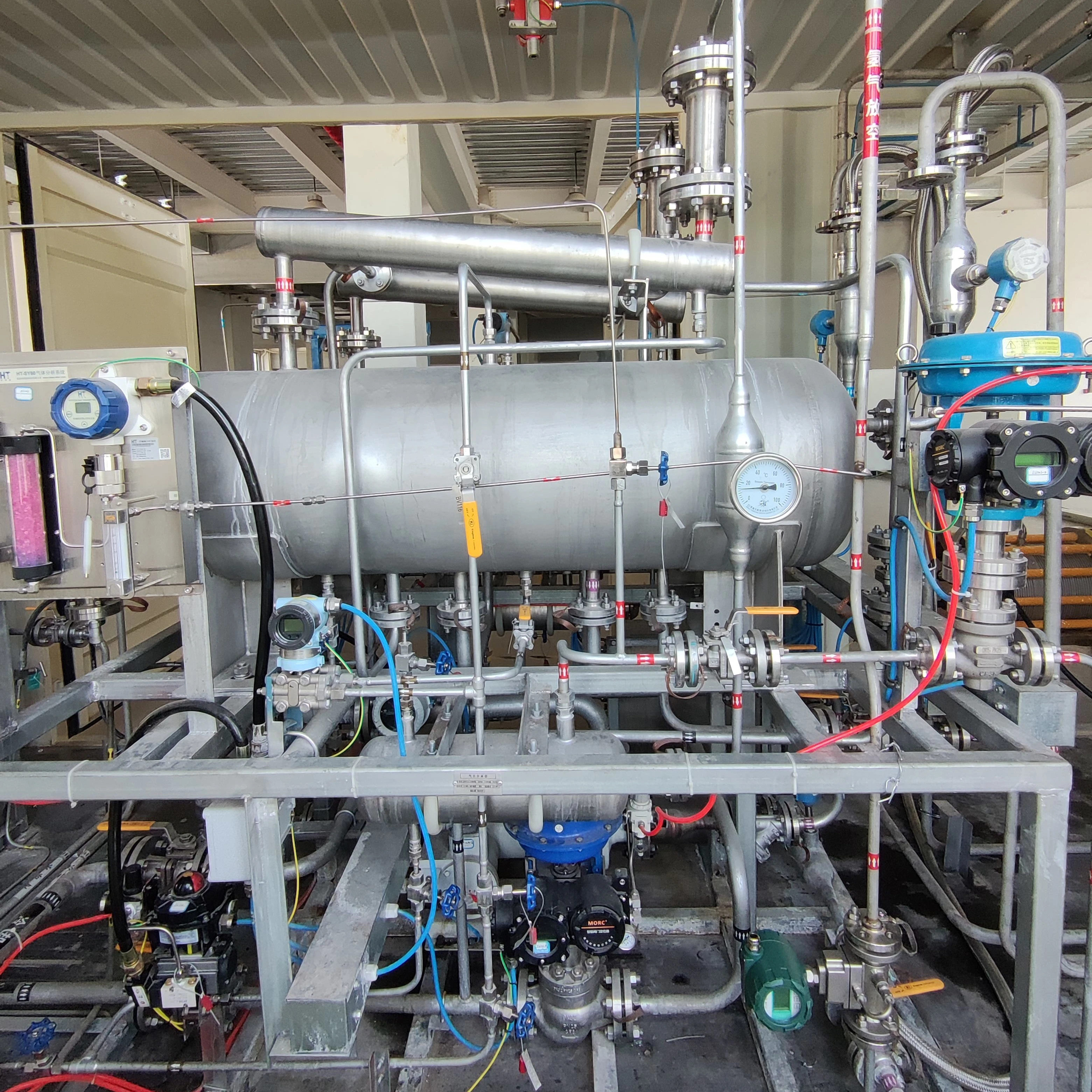

Application showcase

Hydrogen & Oxygen Generator

The Hydrogen & Oxygen Generator is a high-tech product that produces pure hydrogen through electrolysis of water. Hydrogen molecules enter the human body directly from the respiratory system and diffuse to the nose, lungs and brain.

After the hydrogen enters the human body, the hydrogen combines with the malignant oxygen free radicals in the human body and reduces to water, which is excreted in the form of water. After eliminating the malignant free radicals, the human cells return to a balanced state

After the hydrogen enters the human body, the hydrogen combines with the malignant oxygen free radicals in the human body and reduces to water, which is excreted in the form of water. After eliminating the malignant free radicals, the human cells return to a balanced state

Company Introduction

Gatechn New Energy Technology (Shanghai) Co.,Ltd. focuses on the research, development and manufacturing of hydrogen fuel cells, its core materials and key components. It’s a high-tech company and which is dedicated to the Hydrogen Fuel Cell membrane electrode (MEA), hydrogen fuel cell stack system and other related equipment.

The company has developed core materials of hydrogen fuel cell independently, mastered the core technologies of producing various catalysts and membrane electrodes, hydrogen fuel cell stacks and hydrogen fuel cell power systems. The company has developed the whole industrial chain involving hydrogen production and consumption, as well as the application of by-products generated in hydrogen production, etc. the 8 fuel cells production related patents. Moreover, the company has drafted several enterprise standards of "hydrogen fuel cell stack" and "multi-function hydrogen rich machine" production, which have been reviewed and approved by experts.

Our products and services are widely used in many fields such as automotive companies, industrial handling vehicles, communication base stations, unmanned aerial vehicles, standby power supplies, field demonstration emergency power supplies, gas sensors, etc.

The company has developed core materials of hydrogen fuel cell independently, mastered the core technologies of producing various catalysts and membrane electrodes, hydrogen fuel cell stacks and hydrogen fuel cell power systems. The company has developed the whole industrial chain involving hydrogen production and consumption, as well as the application of by-products generated in hydrogen production, etc. the 8 fuel cells production related patents. Moreover, the company has drafted several enterprise standards of "hydrogen fuel cell stack" and "multi-function hydrogen rich machine" production, which have been reviewed and approved by experts.

Our products and services are widely used in many fields such as automotive companies, industrial handling vehicles, communication base stations, unmanned aerial vehicles, standby power supplies, field demonstration emergency power supplies, gas sensors, etc.

Exhibition display

We have applied for 25 fuel cell-related patents, with 5 of them granted.

Packing&Shipping

FAQ

When was your company established? What are your advantages?

We were established in 2019 with the participation of many industry experts. The company is headquartered in Shanghai and the new factory is located in Yangzhou, Jiangsu. Our operations team consists of technical experts with more than 20 years of experience in hydrogen fuel cell research and development.

We have established comprehensive cooperative relationships with many well-known domestic universities and research institutes to provide advanced technical knowledge and resource support for hydrogen fuel cell research and development.

We have exported our products to countries and regions including the United States, Canada, Mexico, France, Spain, Chile, South Korea, Malaysia, India, and Taiwan.

What is the minimum order quantity for your products?

One piece

Do you have it in stock?

No, our products need to be ordered and produced.

What is your delivery time?

Delivery time varies from 5 to 20 business days depending on the order.

Do you provide samples?How to get samples?

Samples are available upon placing an order.

What are your payment terms?

Prepayment 100%

We were established in 2019 with the participation of many industry experts. The company is headquartered in Shanghai and the new factory is located in Yangzhou, Jiangsu. Our operations team consists of technical experts with more than 20 years of experience in hydrogen fuel cell research and development.

We have established comprehensive cooperative relationships with many well-known domestic universities and research institutes to provide advanced technical knowledge and resource support for hydrogen fuel cell research and development.

We have exported our products to countries and regions including the United States, Canada, Mexico, France, Spain, Chile, South Korea, Malaysia, India, and Taiwan.

What are your main products?

Hydrogen Fuel Cell membrane electrode (MEA),PEM CCM, hydrogen fuel cell stack system and other related equipment.

Hydrogen Fuel Cell membrane electrode (MEA),PEM CCM, hydrogen fuel cell stack system and other related equipment.

What is the minimum order quantity for your products?

One piece

Do you have it in stock?

No, our products need to be ordered and produced.

What is your delivery time?

Delivery time varies from 5 to 20 business days depending on the order.

Do you provide samples?How to get samples?

Samples are available upon placing an order.

What are your payment terms?

Prepayment 100%

We Recommend

New Arrivals

New products from manufacturers at wholesale prices